Overview

Applications

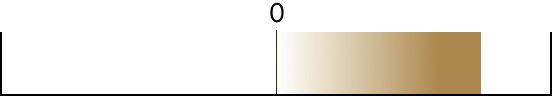

Comparison

Chemical formula

Specific gravity

1.24 (PSU)

Thermal properties

187

Tg(℃)

N/A

Tm(℃)

Characteristics

Heat resistance

Chemical resistance

Low smoke generation

Flow ability

Mechanical properties

Brownish transparency

Commentary

It is a molecular chain composed of sulfone groups and aromatics. The sulfone groups provide thermal and oxidative stability, while the aromatic groups provide heat and chemical resistance.

・PSU: Polycondensation of dichlorophenylsulfone and bisphenol A

・PES: Polycondensation using dichlorophenylsulfone as the main raw material

・PPSU: Polycondensation of dichlorophenylsulfone and biphenyldiol

Key points

- PSU: Continuous use temperature of 175℃, electrical properties, heat resistance, etc. are utilized for connectors, printed circuit boards, etc. Also resistant to hydrolysis, acid, alkali, and oil, and used in food processing and medical equipment

- PES: Continuous use temperature of 180℃, small linear expansion coefficient, high temperature resistance, flame retardant/low smoke, used for severe applications such as automobile and aircraft parts

- PPSU: Continuous use temperature of 180℃, rigid even at high temperatures, high impact resistance compared to PES and PSU, but poor weather resistance.

Large tray for surgical instruments (PPSU)

Reason for adoption

Resistance to long-term, repeated autoclave sterilization at 138°C, chemical resistance, and impact resistance

Source www.solvay.comParts for medical equipment such as ventilators (PSU)

Reason for adoption

Autoclave sterilization resistance and various certifications for medical devices

Source Solvay Specialty Polymers JapanBaby bottle (PPSU)

Reason for adoption

Resistance to boiling and steam disinfection (heat resistance, hydrolysis resistance), chemical resistance Resistance to cracking when dropped (toughness), transparency

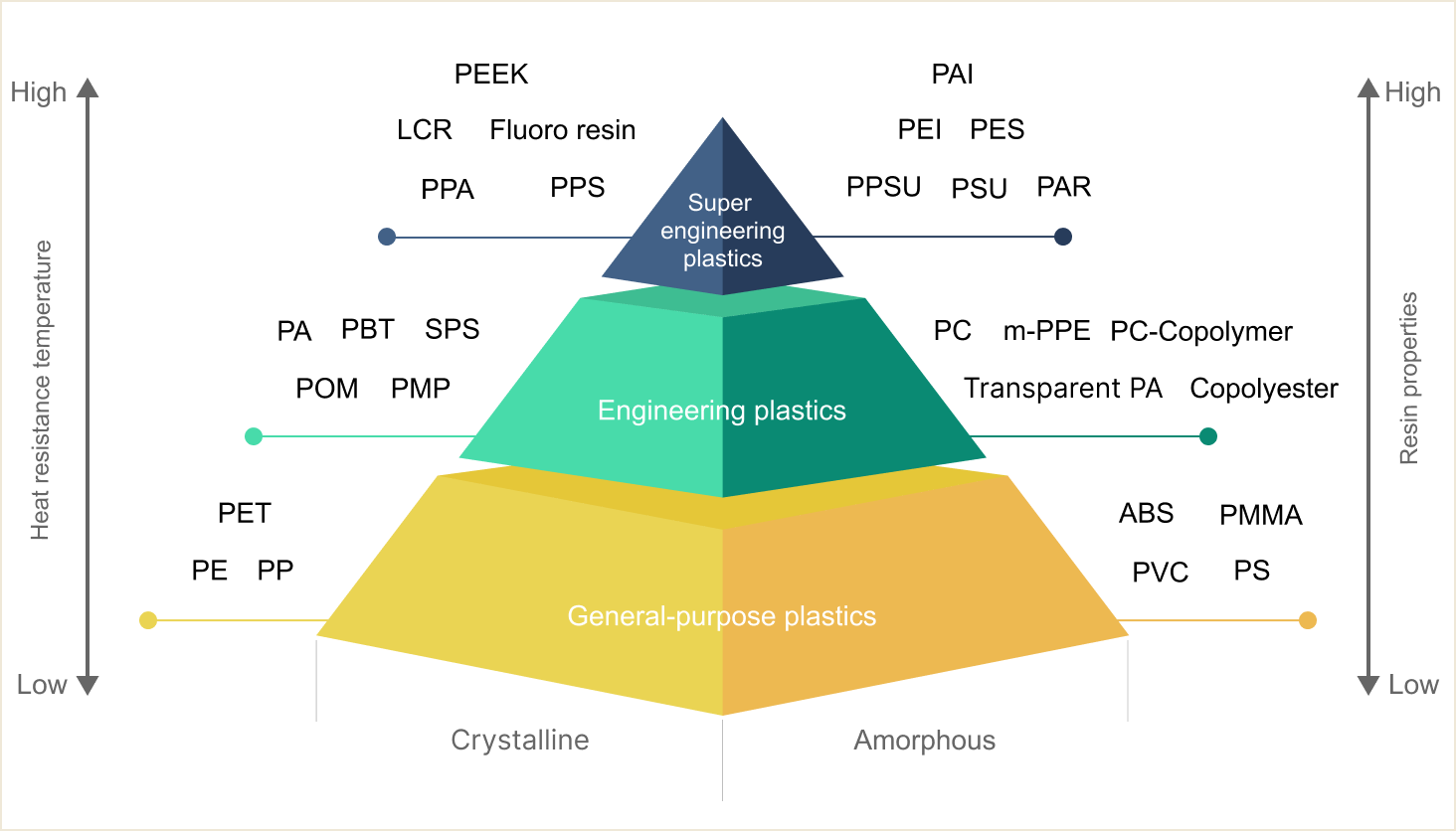

Crystalline

Polyethylene

Polypropylene

Polyethylene

Terephthalate

Polyoxymetylene /

Polyacetal

Polybutylene

Terephthalate

Polyamide 6 /

Polyamide 66

Syndiotactic

Polystyrene

Poly Phenylene Sulfide

Polyphthalamide

Liquid Crystal Polymer

Fluorocarbon Polymers

Polyether-etherketone

Polymethyl-pentene