Overview

Applications

Comparison

Chemical formula

Specific gravity

1.27

Thermal properties

217

Tg(℃)

N/A

Tm(℃)

Characteristics

Heat resistance

Mechanical properties

Flame retardancy

Low smoke generation

Chemical resistance

Brownish transparency

Hydrolysis resistance

Flow ability

Commentary

It is obtained by synthesizing 2,2-bis[4-(3,4-dicarboxyphenoxy)phenyl]propane and m-phenylenediamine in the presence of organic solvents. It combines imide bonding (excellent heat resistance and strength) with ether bonding (good processability).

Key points

- It is used for aircraft interior parts because of its high flame resistance and low smoke and toxic gas emission even if it burns.

- It has similar performance to sulfone super engineering plastics, and PEI is selected for applications and processes where sulfur should be avoided.

Fiber Optic Communication Connectors

Reason for adoption

Near-infrared transparency, withstands PCB reflow soldering (260°C) without filler reinforcement (heat resistance, low coefficient of linear expansion, dimensional stability)

Source PressReleaseFinderWDM (wavelength division multiplexing) module

Reason for adoption

High level infrared transmittance (over 88% at 850-1550nm), high refractive index, dimensional stability at high temperatures, more design flexibility than aspherical glass lenses, mass production and high speed production are possible.

Source PressReleaseFinderAR Smart Glasses Temples

Reason for adoption

Thinner temples with a balance of ductility and rigidity (to reduce weight and provide space for electronic components)

Source PressReleaseFinder

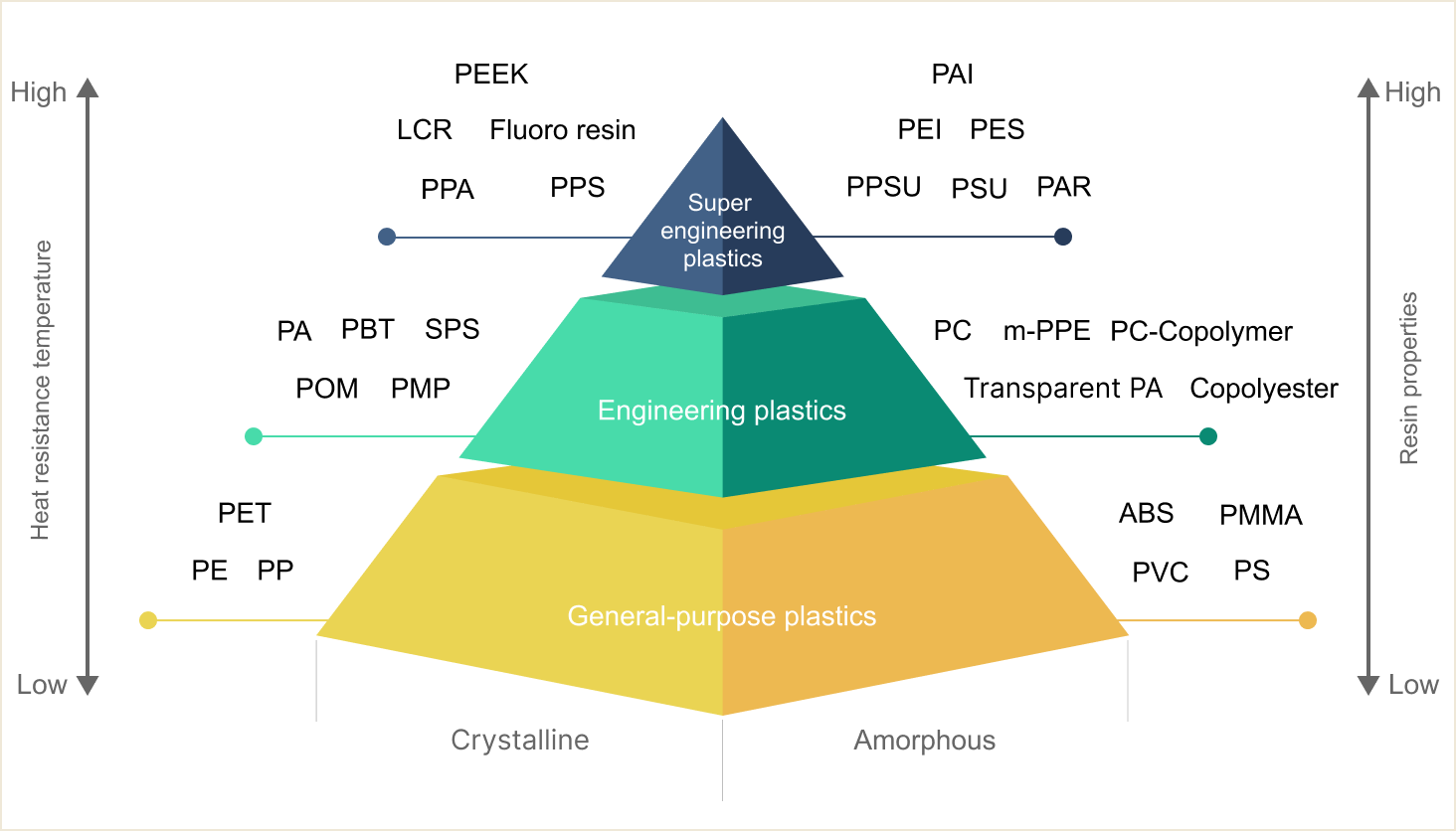

Crystalline

Polyethylene

Polypropylene

Polyethylene

Terephthalate

Polyoxymetylene /

Polyacetal

Polybutylene

Terephthalate

Polyamide 6 /

Polyamide 66

Syndiotactic

Polystyrene

Poly Phenylene Sulfide

Polyphthalamide

Liquid Crystal Polymer

Fluorocarbon Polymers

Polyether-etherketone

Polymethyl-pentene