Overview

Applications

Comparison

Chemical formula

Specific gravity

1.42

Thermal properties

275

Tg(℃)

N/A

Tm(℃)

Characteristics

Ultra heat resistance

Impact resistance

Fatigue resistance

Sliding resistance

Low CTE

Low creep

Chemical resistance

Moldability

Commentary

It is synthesized by the decarboxylation reaction of trimellitic anhydride and methylene diphenyl isocyanate. In order to improve the moldability of PI (polyimide), an amide bond is incorporated into the main chain.

Key points

- Although it is amorphous, it has chemical resistance and abrasion resistance, and can withstand high continuous use temperatures (approximately 275°C), so it is used in sliding gears that can withstand high temperatures.

- To make molding easier, the molding process is carried out with a relatively low molecular weight, and a post-cure process is carried out to improve the performance of the molded parts.

- If molding is interrupted or the molding cycle is too long, there is a risk that hardening will begin inside the cylinder.

Labyrinth Seal

Reason for adoption

Dimensional stability (low coefficient of linear expansion, creep resistance), corrosion resistance, friction and wear resistance under all temperature environments

Source Solvay Specialty Polymers JapanAircraft Engine Shroud

Reason for adoption

Weight reduction by metal substitution

Source Solvay Specialty Polymers JapanAircraft Connectors

Reason for adoption

Toughness and thermal properties for long-term use, excellent flame resistance and electrical insulation

Source Solvay Specialty Polymers Japan

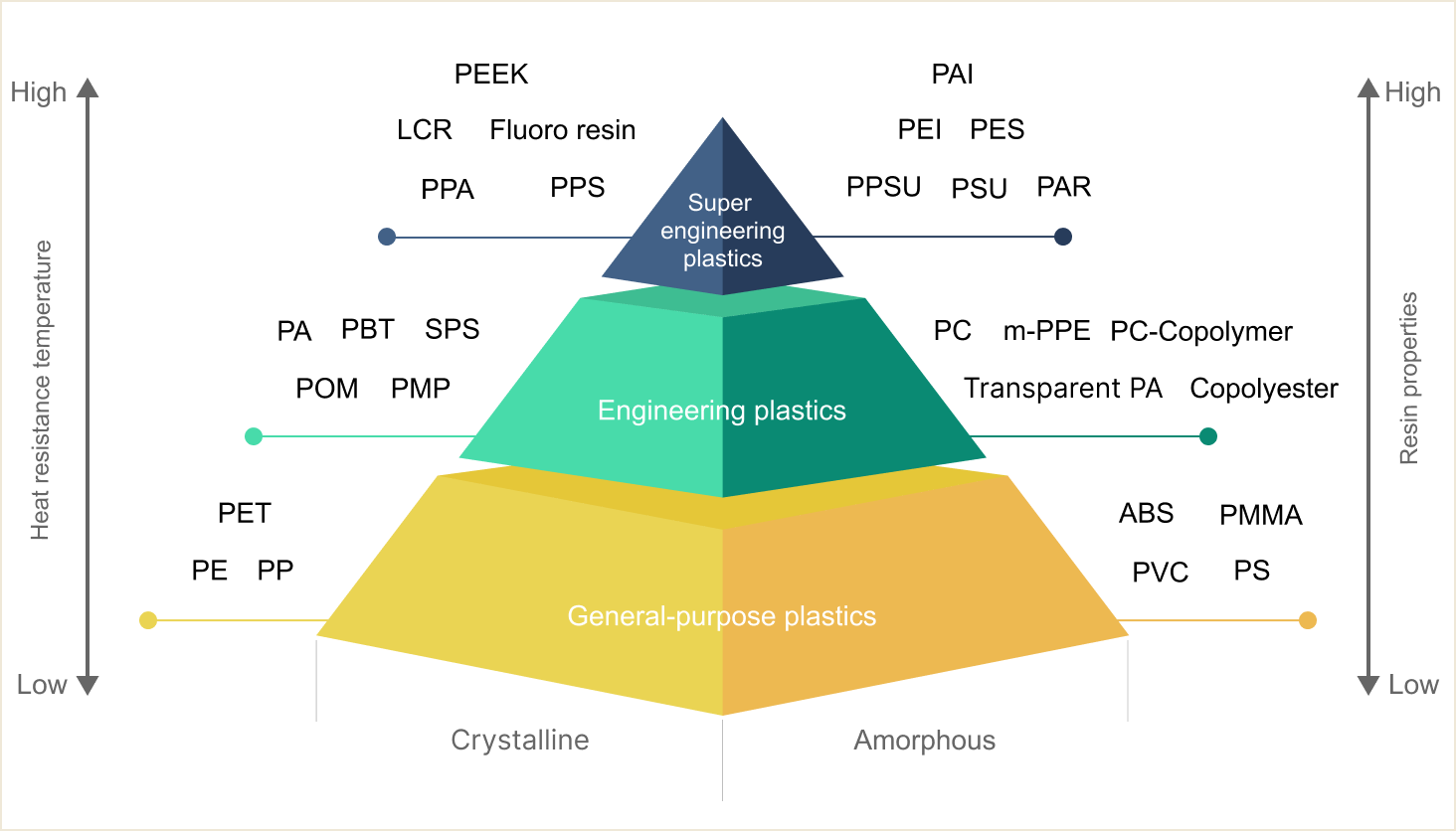

Crystalline

Polyethylene

Polypropylene

Polyethylene

Terephthalate

Polyoxymetylene /

Polyacetal

Polybutylene

Terephthalate

Polyamide 6 /

Polyamide 66

Syndiotactic

Polystyrene

Poly Phenylene Sulfide

Polyphthalamide

Liquid Crystal Polymer

Fluorocarbon Polymers

Polyether-etherketone

Polymethyl-pentene