Overview

Applications

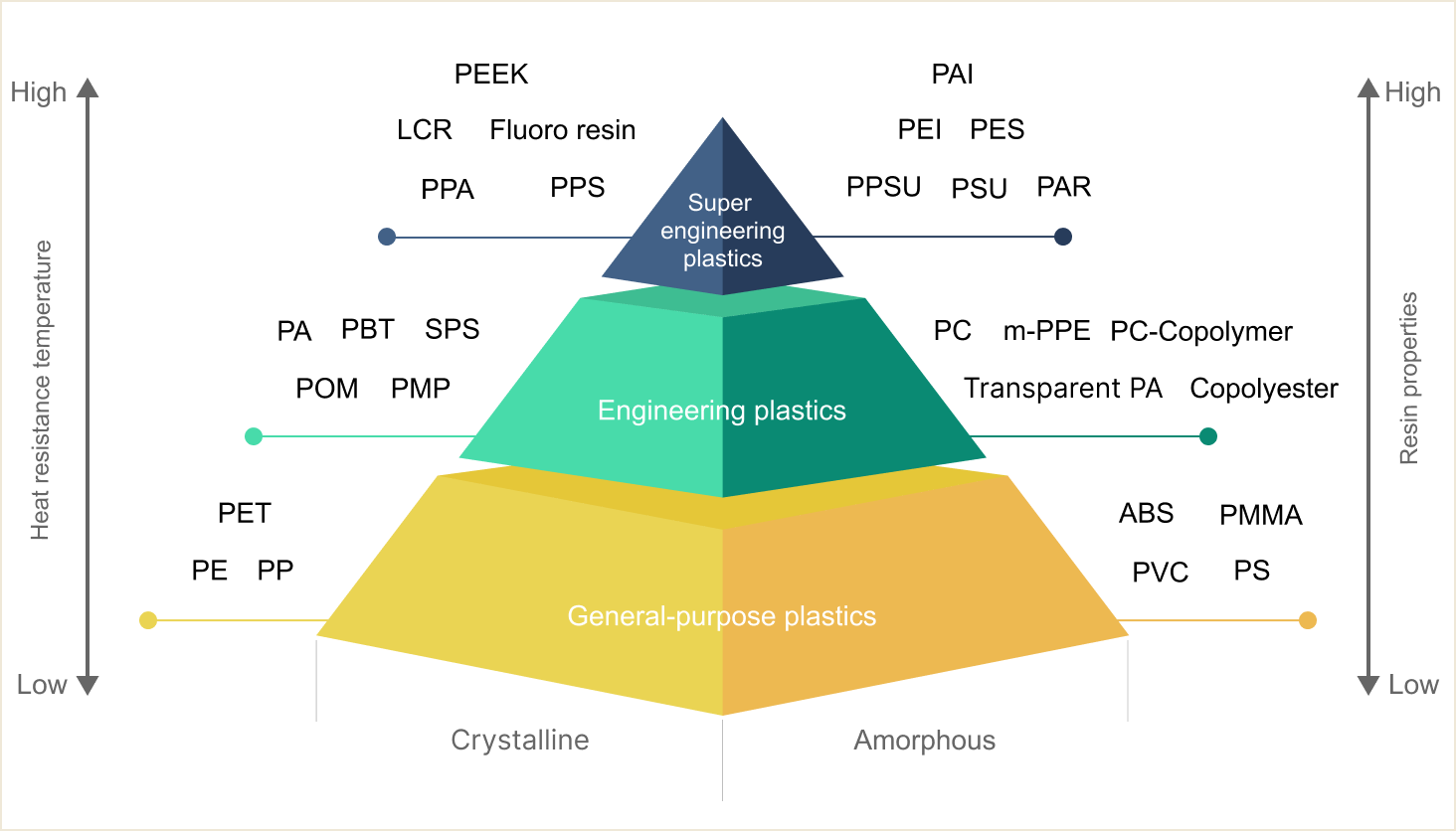

Comparison

Chemical formula

※PTFE

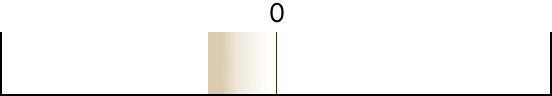

Specific gravity

1.7-2.2

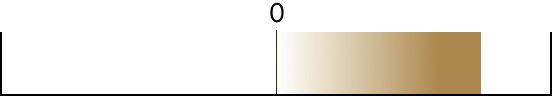

Thermal properties

-40

Tg(℃)

170~

Tm(℃)

Characteristics

Heat resistance

Cold resistance

Sliding property

Non-adhesiveness

Flame retardancy

Chemical resistance

Weatherabilty

Electrical properties

Flow ability

Commentary

A group of polymers obtained by polymerizing fluorine. There are variations with different properties, such as fully fluorinated, partially fluorinated, and copolymers with other polymers.

PTFE: Continuous use temperature 260℃, most commonly used among fluororesins, cutting from compression molded blocks, coating for frying pans, etc.

FEP: Continuous use temperature 200℃, thermal melt molding possible

PFA: Continuous use temperature 260℃, thermal melt molding possible, transparency

ETFE: Continuous use temperature 150℃, copolymer with ethylene, has intermediate properties between PTFE and PE, hot melt molding possible

PCTFE: Continuous use temperature 120℃, good water vapor barrier properties, thermal melt molding possible

PVDF: Continuous use temperature 130℃, good mechanical properties and impact strength among fluororesins

ECTFE: Continuous use temperature 160℃, specific gravity is small among fluororesins

Key points

- Continuous use temperature is about 260℃. It is also highly flame-retardant and slippery, so it is famous for its use as a coating for frying pans.

- It is also used as an exterior wall material for facilities because it has good weather resistance, low wear and friction, water and oil repellency, chemical resistance, and an oxygen index of 95 or higher, making it highly flame-retardant.

Frying pan coating (Teflon coated)

Reason for adoption

Resistant to heat, slides well, does not stick, and is not flammable

Airport Roofing Materials

Reason for adoption

Easily coated, stain resistance (non-adhesiveness), weather resistance, moisture resistance

Surgical and N95 air filtration masks

Reason for adoption

Electric field spinnability in nanofiber production, air permeability, and maintenance of filter performance over a long period of time (high durability)

Source www.solvay.com

Crystalline

Polyethylene

Polypropylene

Polyethylene

Terephthalate

Polyoxymetylene /

Polyacetal

Polybutylene

Terephthalate

Polyamide 6 /

Polyamide 66

Syndiotactic

Polystyrene

Poly Phenylene Sulfide

Polyphthalamide

Liquid Crystal Polymer

Fluorocarbon Polymers

Polyether-etherketone

Polymethyl-pentene