Overview

Applications

Comparison

Chemical formula

※Typical example

Specific gravity

1.62 (GF30%)

Thermal properties

N/A

Tg(℃)

280~

Tm(℃)

Characteristics

Heat resistance

Good flowability

Low thermal expansion

Low water absorption

Low molding shrinkage

Mechanical strength

Electrical properties

Impact resistance

Wear resistanse

Outgassing

Commentary

The structure is based on para-hydroxybenzoic acid.

Classified into Type I, II, and III according to heat resistance level.

No obviousTg or Tm, gradually softens with temperature

Key points

- Generally, crystalline plastics are decrystallized when melted (molded).

- However, LCP melts in a state where the molecules are regularly arranged (liquid crystal state) due to strong intermolecular forces.

- As a result, shrinkage is less likely to occur and the viscosity is low, making it possible to accommodate fine designs, and it has a linear expansion coefficient close to that of metals and high dimensional stability.

Electronics for surface mount technology

Reason for adoption

Capable of withstanding high temperatures, fine design molding (heat resistance, good flowability, low shrinkage, low linear expansion, mechanical strength in MD direction)

Narrow Pitch Connectors

Reason for adoption

Moldability for detailed design (good flowability, low shrinkage, low linear expansion, mechanical strength in MD direction)

Camera Module

Reason for adoption

Moldability for detailed design (good flowability, low shrinkage, low linear expansion, mechanical strength in MD direction) and dimensional stability

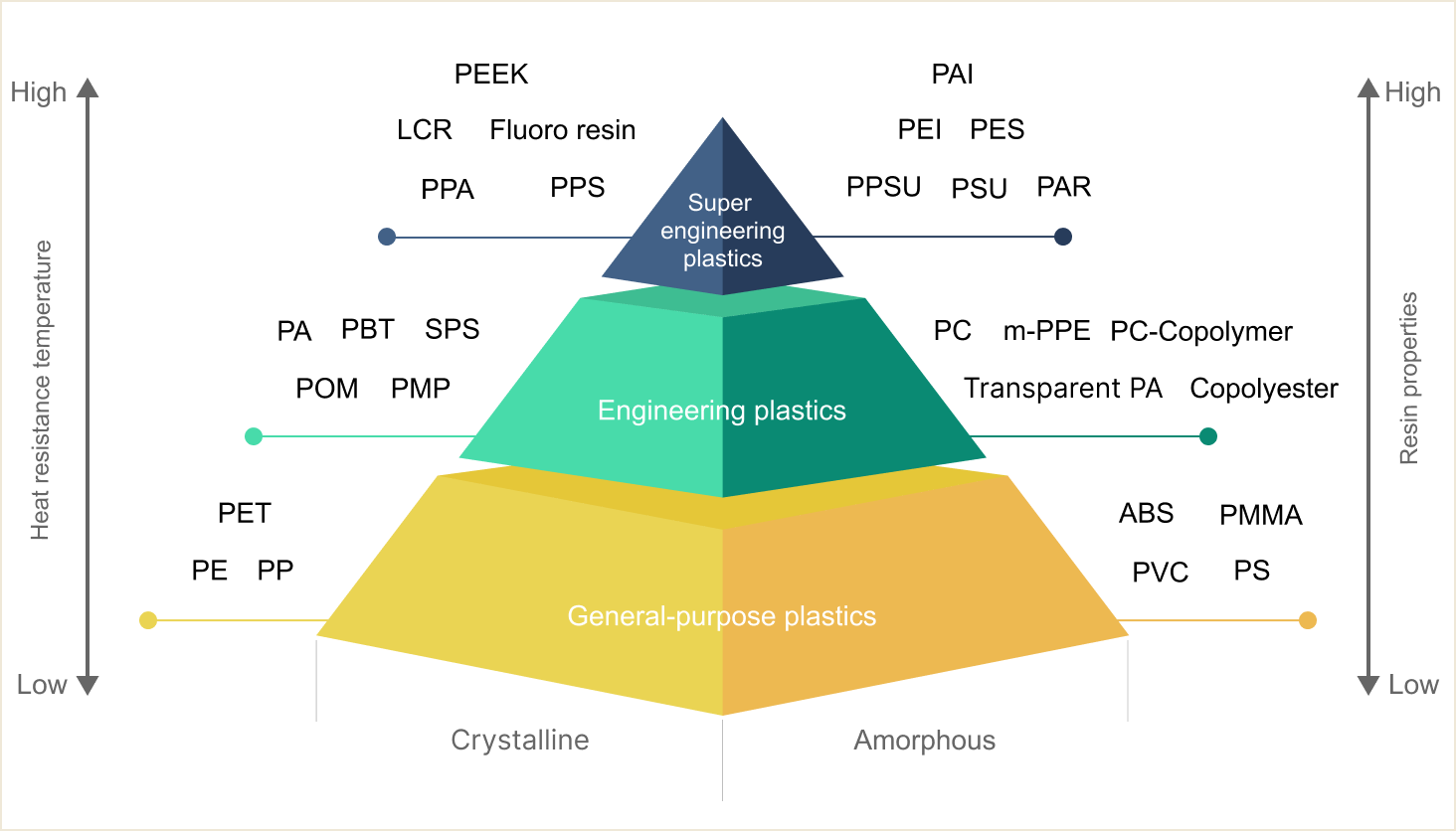

Crystalline

Polyethylene

Polypropylene

Polyethylene

Terephthalate

Polyoxymetylene /

Polyacetal

Polybutylene

Terephthalate

Polyamide 6 /

Polyamide 66

Syndiotactic

Polystyrene

Poly Phenylene Sulfide

Polyphthalamide

Liquid Crystal Polymer

Fluorocarbon Polymers

Polyether-etherketone

Polymethyl-pentene