Overview

Applications

Comparison

Chemical formula

Specific gravity

1.04

Thermal properties

100

Tg(℃)

N/A

Tm(℃)

Characteristics

Balance of physical properties

Moldability

Paintability

Plating

Dimensional stability

Flame retardancy

Commentary

・ABS:Ternary copolymers of acrylonitrile, butadiene, and styrene.

・AS: acrilonitrile and stylene without butadiene

・AAS: polymerized with acrylic rubber instead of butadiene

・ACS:polymerized withchlorinatedPEinstead of butadiene

・AES:polymerized withEPDMinstead of butadiene

Key points

- Molding materials with excellent balance of heat resistance, mechanical properties, impact resistance, moldability, paintability, etc.

- And it is used in many applications.

Front grill

Reason for adoption

Metallic appearance (platability), hard to deform, rigid, and hard to crack (balance of physical properties)

Toner cartridge

Reason for adoption

Few deformation over time due to use (balance of physical properties), Good at injection molding and secondary processing (assembly, welding, etc.)

Helmets for construction sites

Reason for adoption

Crack-resistant and lightweight (impact resistance, low specific gravity)

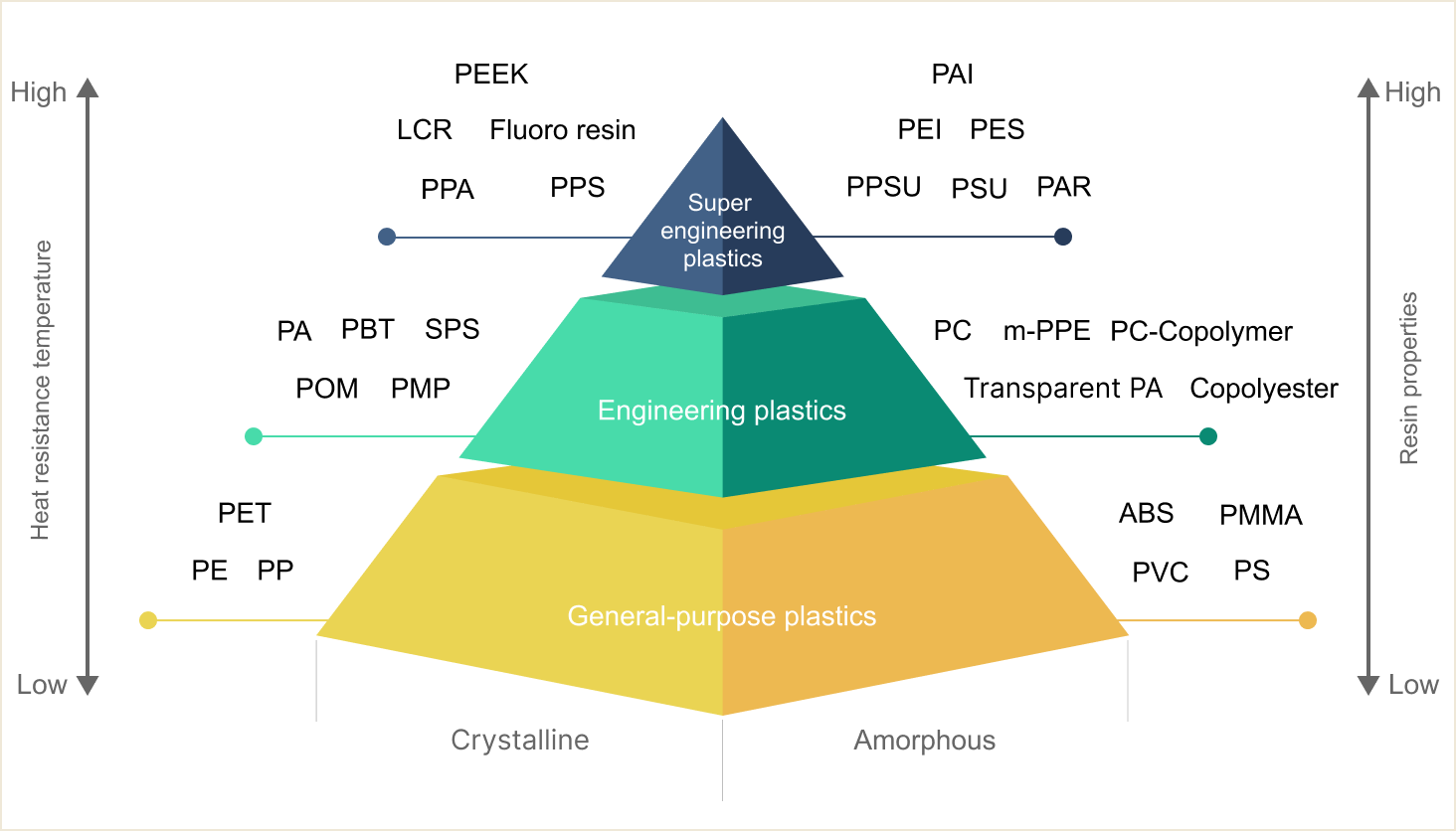

Crystalline

Polyethylene

Polypropylene

Polyethylene

Terephthalate

Polyoxymetylene /

Polyacetal

Polybutylene

Terephthalate

Polyamide 6 /

Polyamide 66

Syndiotactic

Polystyrene

Poly Phenylene Sulfide

Polyphthalamide

Liquid Crystal Polymer

Fluorocarbon Polymers

Polyether-etherketone

Polymethyl-pentene