Overview

Applications

Comparison

Chemical formula

Specific gravity

1.66 (GF40%)

Thermal properties

90

Tg(℃)

280

Tm(℃)

Characteristics

Ultra heat resistance

Mechanical properties

Chemical resistance

Low water absorption

Molding dimensional accuracy

Electrical insulation

Flame retardancy

Impact resistance

Commentary

A polymer consisting of benzene rings linked by sulfur, produced by polycondensation of paradichlorobenzene and sodium sulfide. It is a material with good flowability and is easily reinforced with filler. 40% glass fiber grades is the standard.

Key points

- Unreinforced products are easily cracked by impact. Therefore, many grades are reinforced with fillers such as glass fiber.

- Filler-reinforced products have good mechanical properties and are chemically resistant, heat resistant, and flame retardant.

- Since the main chain contains sulfur, corrosive gases may be generated during high-temperature molding.

Connection ring

Reason for adoption

High insulation, high volume resistivity, excellent strength and fatigue resistance under severe heat cycles

Source PressReleaseFinderPiping fittings for hot water

Reason for adoption

Hydrolysis resistance (to hot water), impact resistance (to water hammer), high rigidity, low water absorption

Source Nix, Inc.48-volt inverter module

Reason for adoption

Insert formability with copper (approximate coefficient of thermal expansion), thermal shock resistance, virtually zero water absorption

Source PressReleaseFinder

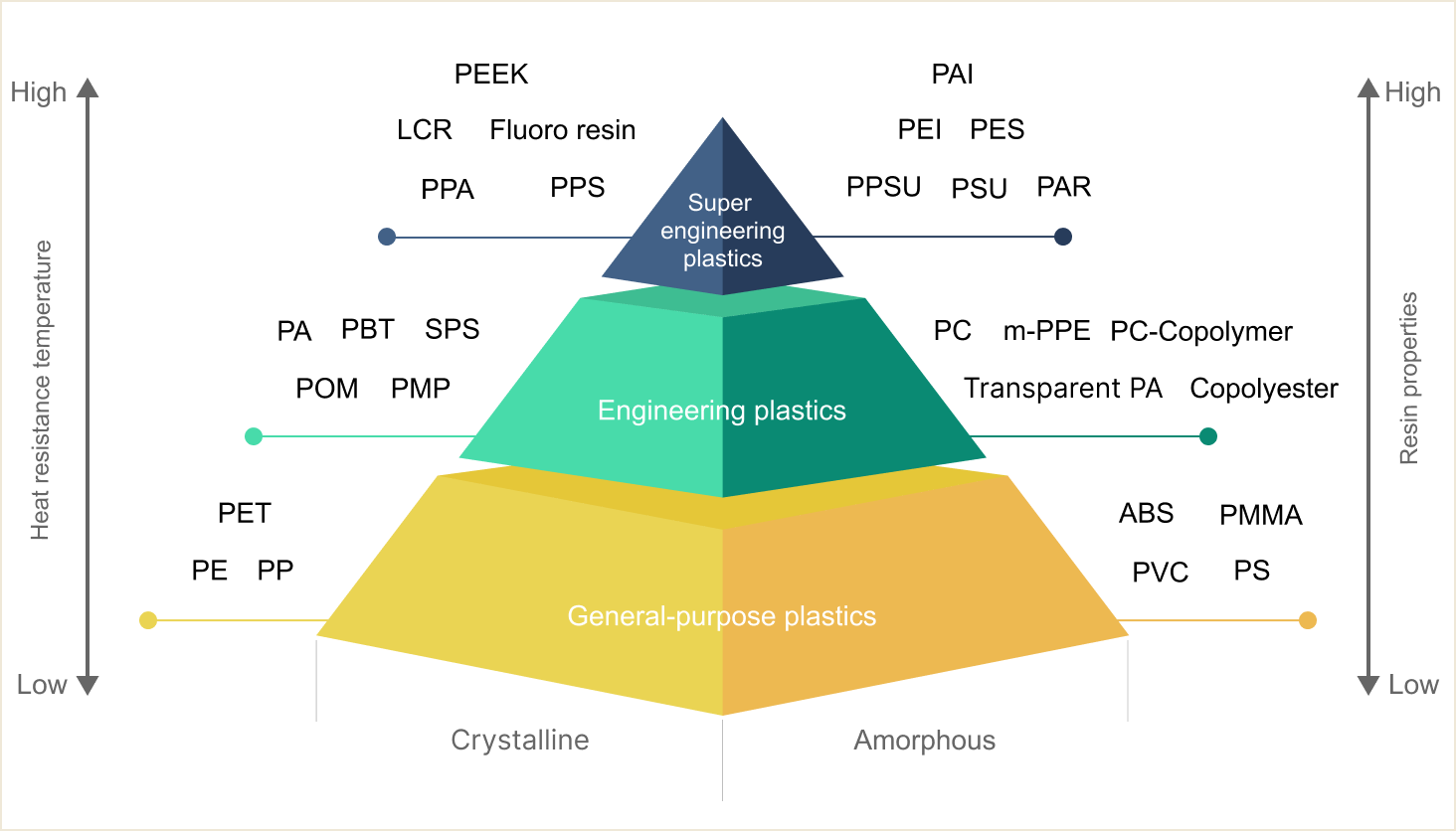

Crystalline

Polyethylene

Polypropylene

Polyethylene

Terephthalate

Polyoxymetylene /

Polyacetal

Polybutylene

Terephthalate

Polyamide 6 /

Polyamide 66

Syndiotactic

Polystyrene

Poly Phenylene Sulfide

Polyphthalamide

Liquid Crystal Polymer

Fluorocarbon Polymers

Polyether-etherketone

Polymethyl-pentene