Overview

Applications

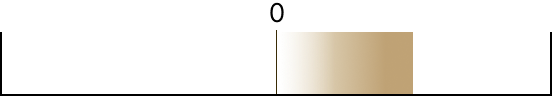

Comparison

Chemical formula

Specific gravity

1.08

Thermal properties

100~

Tg(℃)

N/A

Tm(℃)

Characteristics

Dimensional stability

Flame retardancy

Balance of mechanical properties

Heat resistance

Water resistance

Electrical properties

Acid/alkali resistance

Oil resistance

Commentary

Amorphous PPE is formed by oxidative coupling polymerization of 2,6-xylenol. This PPE alone is not suitable for injection molding, but by blending it with PS, it becomes an easy-to-use material.

-PPE/PS: This is the mainstream of m-PPE, and has a good balance of heat resistance, flame retardancy, and mechanical properties.

-PPE/PA: PPE is used as a heat-resistant organic filler for PA, improving PA's dimensional stability, paintability, and low-temperature impact resistance.

-PPE/PP: PPE is used as a heat-resistant organic filler for PP, improving PP's dimensional stability, heat resistance, and impact resistance.

Key points

- PPE/PS: PPE and PS are completely compatible and have a glass transition temperature (Tg) of one point. Therefore, heat resistance differs depending on the mixing ratio of PPE and PS.

- It is also possible to obtain a high level of flame retardancy without using bromine- or chlorine-based flame retardants.

- Easily yellows when exposed to ultraviolet rays.

EV Battery Module

Reason for adoption

Balanced mechanical properties, good at electrical insulation, resistant to acids, alkalis and humidity, it has a low specific gravity among engineering plastics

Source PressReleaseFinderFender (PPE/PA type)

Reason for adoption

Can be painted in the same way as the body on the body painting line (heat resistance, dimensional stability, impact resistance) Lighter than sheet metal (low specific gravity)

Source PressReleaseFinderPiping Valves

Reason for adoption

Little change in physical properties due to water (water resistance, low water absorption rate), withstands water pressure (creep fracture resistance), complies with drinking water certifications in various countries around the world

Source PressReleaseFinder

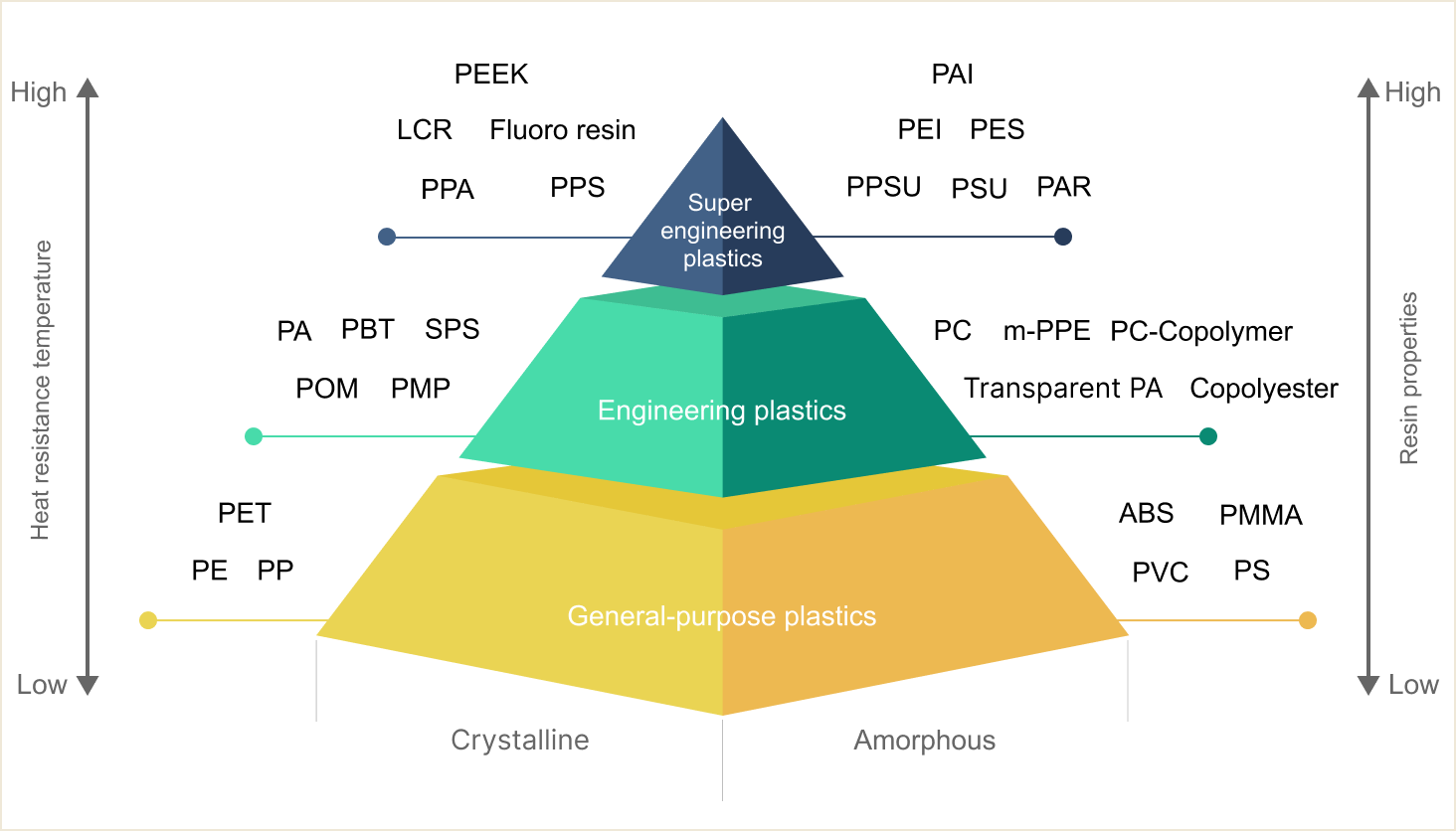

Crystalline

Polyethylene

Polypropylene

Polyethylene

Terephthalate

Polyoxymetylene /

Polyacetal

Polybutylene

Terephthalate

Polyamide 6 /

Polyamide 66

Syndiotactic

Polystyrene

Poly Phenylene Sulfide

Polyphthalamide

Liquid Crystal Polymer

Fluorocarbon Polymers

Polyether-etherketone

Polymethyl-pentene