Overview

Applications

Comparison

Chemical formula

Specific gravity

1.21

Thermal properties

193

Tg(℃)

N/A

Tm(℃)

Characteristics

Dimensional stability

Impact resistance

Flame retardancy

Weatherabilty

Elastic deformation recovery characteristics

Electrical properties

Chemical resistance

Difficult to injection mold

Commentary

It is synthesized by interfacial polymerization of bisphenol A and dicarboxylic acid chloride.

Key points

- An amorphous transparent resin with heat resistance of 193℃.

- Features include high impact strength, weather resistance, and creep resistance.

- It is similar to polycarbonate resin in performance, and it is often used when the heat resistance and chemical resistance of polycarbonate resin is insufficient.

- Reflow solder process compatible grades with even higher heat resistance (Tg265°C) and alloy grades with improved chemical resistance by alloying with polyester are also available.

Automotive lamp reflectors

Reason for adoption

Shape retention in areas close to heat sources (heat resistance), lightweight due to thin-wall molding (high flowability)

Source UNITIKASensor lens, sensor cover

Reason for adoption

Transparency usable as a sensor, chemical resistance (especially to oil, alcohol, etc.), control of transmission wavelength and appearance (color-tuning technology)

Source UNITIKAImplant Kit Case

Reason for adoption

Endure at Autoclave heat (heat and moisture resistant), transparent

Source UNITIKA

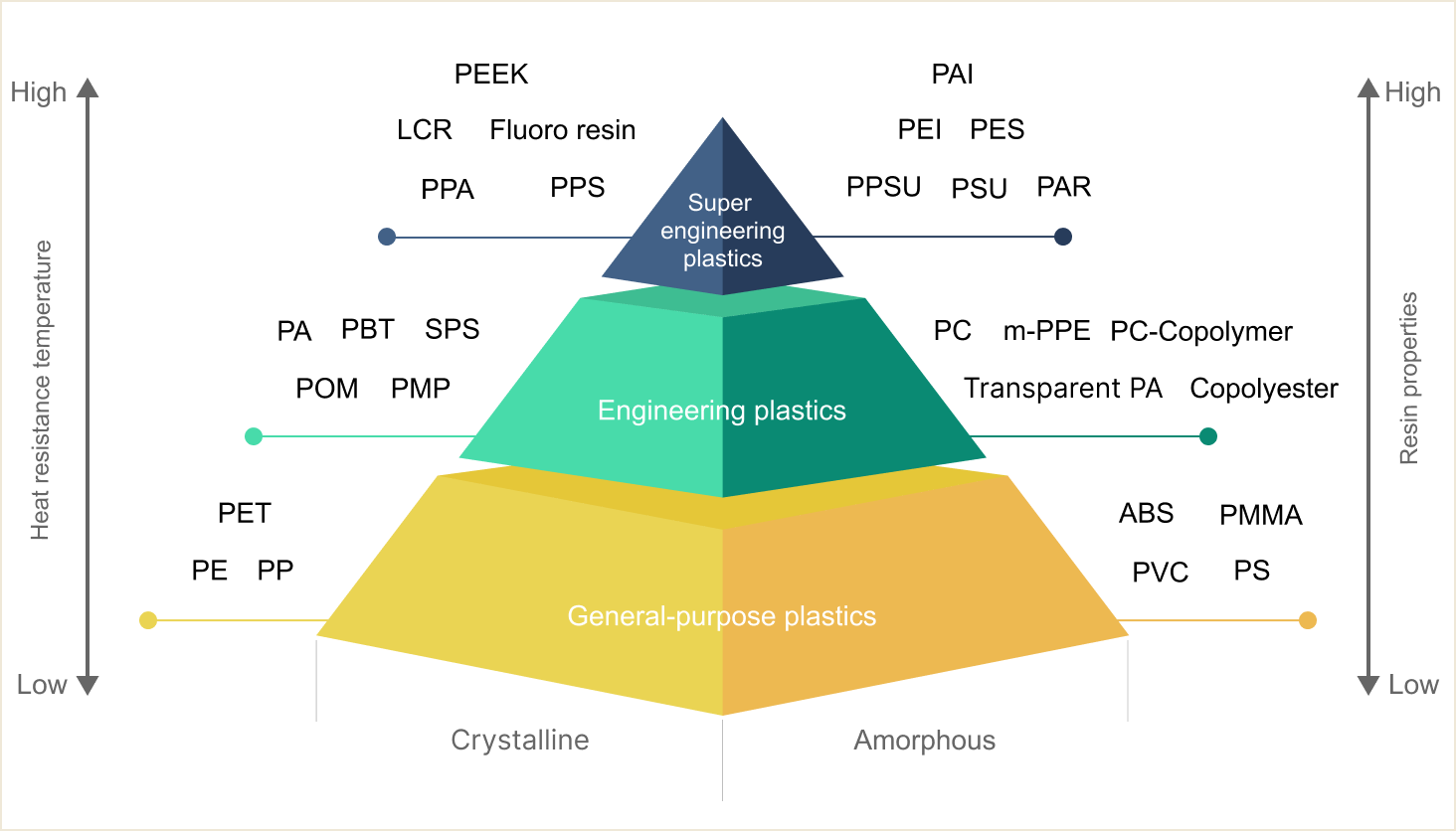

Crystalline

Polyethylene

Polypropylene

Polyethylene

Terephthalate

Polyoxymetylene /

Polyacetal

Polybutylene

Terephthalate

Polyamide 6 /

Polyamide 66

Syndiotactic

Polystyrene

Poly Phenylene Sulfide

Polyphthalamide

Liquid Crystal Polymer

Fluorocarbon Polymers

Polyether-etherketone

Polymethyl-pentene