Sustainable Stories

Nagase Viita's WEB Magazine

04Story

August 09, 2022

Giving a new value to a locally produced Japanese paper materialYUNOKA Cosmetics with Mitsumata Extract

Mitsumata (oriental paperbush) was once widely cultivated in the mountain hamlet of Maniwa, Okayama Prefecture. Collaboration between industry and academia revealed that mitsumata, a plant used since ancient times in traditional Japanese washi paper and currency, had a new value—inhibiting melanin production. And thus, an original cosmetic brand, kind to both the skin and the environment, was created. Prompted by this development, the local area has also launched initiatives to revitalize mitsumata cultivation and pass down the culture of traditional Japanese paper making.

A homegrown cosmetic brand based on the concept of beautiful Japanese skin

Yunoka is a cosmetics series using mitsumata from the Kashimura area. The series currently includes three items, serum, lift lotion and soap. These products are rapidly gaining fans for delivering hydrated, firm and clear skin.

These are the first cosmetics in the world to use mitsumata bark extract as a cosmetic ingredient. The man who realized that mitsumata bark had melanin inhibiting properties and commercialized it was Yasushi Naito, a corporate executive previously unrelated to cosmetics in any way.

Taking hints from the beautiful hands of traditional Japanese paper artisans

▲Paper making. Boiling and soaking the mitsumata bark, and mixing in starch to create the paper liquid. The artisan moves the suketa frame back-and-forth and side-to-side, making the fibers contained in the paper liquid thin and uniform. The Japanese washi paper is finished once the water is drained away and the paper is dried. Traditionally, papermaking is done during the coldest part of winter when the starch is most effective.

▲Paper making. Boiling and soaking the mitsumata bark, and mixing in starch to create the paper liquid. The artisan moves the suketa frame back-and-forth and side-to-side, making the fibers contained in the paper liquid thin and uniform. The Japanese washi paper is finished once the water is drained away and the paper is dried. Traditionally, papermaking is done during the coldest part of winter when the starch is most effective.

HK Corporation, where Naito serves as chairperson, had handled fuel and rice as its primary business for many years. Naito explains that he first got the idea for developing cosmetics when he visited a local Japanese paper factory about creating the packaging for a rice gift product he was planning.

▲Yasushi Naito (President of YUNOKA Co., Ltd. / Chairperson of HK Corporation)

▲Yasushi Naito (President of YUNOKA Co., Ltd. / Chairperson of HK Corporation)

▲Yasushi Naito (President of YUNOKA Co., Ltd. / Chairperson of HK Corporation)

▲Yasushi Naito (President of YUNOKA Co., Ltd. / Chairperson of HK Corporation)

“I want to create a new value for mitsumata, this local, specialty product.” His idea gathered energy and got local people involved.

Naito didn’t know the first thing about cosmetics development when he first started, but he received numerous introductions over the course of his inquiries, eventually leading him to meet cosmetic science expert Professor Hideya Ando of the Okayama University of Science. Naito promptly boiled down the mitsumata bark himself and brought the liquid extract to Professor Ando for evaluation. After completing detailed analysis, even the professor himself was surprised, remarking “This is the most significant discovery I’ve been involved with!” His analysis revealed that the extract clearly inhibited melanin production.

Naito would then overcome numerous hurdles to move forward with commercialization, and four long years after the original idea, he was finally able to launch Yunoka White Serum in 2017.

The product attracted attention as an original cosmetic created in a traditional Japanese paper-making town. And the year following the product launch, Yunoka White Serum received the grand prize from the 2018 47 Club Konna no Arunda Awards, determined by recommendations and evaluations from regional newspapers nationwide, over approximately 35,000 other regional products. Then in 2020, the Okayama University of Science and HK Corporation collaborated and successfully obtained a patent for the invention of “a melanin-production reducing agent.”

Cosmetics that bring happiness to customers, manufacturers and local communities

As you would expect, the mitsumata used in Yunoka is all produced locally in Maniwa. And after the extract has been taken, the remaining fibers are ready to be made into paper, so disposal loss can be prevented.

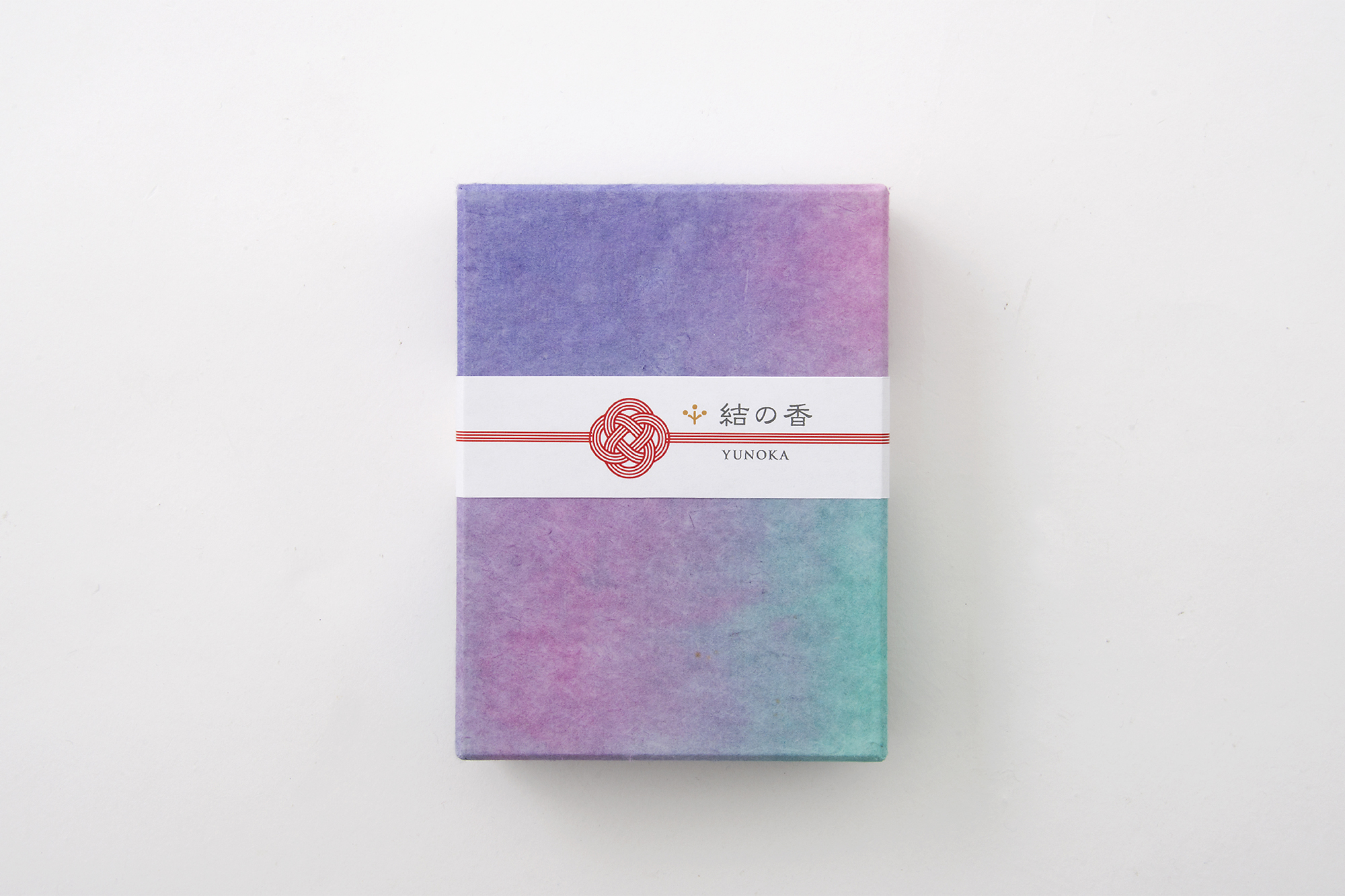

The original mitsumata Japanese paper packaging for the product set is a special item that symbolizes the Yunoka brand. Each piece with its own unique beauty, this traditional Japanese paper is made and dyed locally at the Kashinishi Japanese Paper Factory. Many customers report that they keep and use the empty box with great care, leading to a rediscovered appreciation for the charms of traditional Japanese paper.

The development of Yunoka also led to increased interest in revitalizing mitsumata cultivation in the Kashimura area. In 2019, local volunteers launched a crowdfunding effort and achieved their target financial goal. They used this funding for activities such as mitsumata cultivation and interactive learning experiences, etc., helping to pass this traditional culture on to children.

The original mitsumata Japanese paper packaging for the product set is a special item that symbolizes the Yunoka brand. Each piece with its own unique beauty, this traditional Japanese paper is made and dyed locally at the Kashinishi Japanese Paper Factory. Many customers report that they keep and use the empty box with great care, leading to a rediscovered appreciation for the charms of traditional Japanese paper.

The development of Yunoka also led to increased interest in revitalizing mitsumata cultivation in the Kashimura area. In 2019, local volunteers launched a crowdfunding effort and achieved their target financial goal. They used this funding for activities such as mitsumata cultivation and interactive learning experiences, etc., helping to pass this traditional culture on to children.

(Right)Local volunteers planting mitsumata in an effort to revitalize this traditional mitsumata town

Naito says that “Because I’d learned by chance that this local resource, mitsumata, had an amazing quality, I wanted that value to benefit the local community somehow, and that was my entire focus. If I’d just wanted to make money, I couldn’t have worked as hard as I did.”

The more they are used, the more these products both moisturize the skin and energize local industry and culture. Naito hopes to continue expanding the network of people who agree and use these products.

The more they are used, the more these products both moisturize the skin and energize local industry and culture. Naito hopes to continue expanding the network of people who agree and use these products.

The Nagase Viita personal care ingredients used in Yunoka

Yunoka products also use Nagase Viita ingredients as cosmetic ingredients.

In addition to mitsumata, Naito wanted to use local ingredients connected to Okayama as much as possible while developing his products, so he chose Nagase Viita ingredients.

The AA2G™(Ascorbyl Glucoside) contained in the serum is a vitamin C derivative featuring Nagase Viita enzymatic technology that stabilizes easily changeable vitamin C by binding it to glucose. With a proven record as an active ingredient in quasi-drugs, this ingredient inhibits melanin production to reduce age spots and freckles.

The Glucosyl Naringin used in the lift lotion binds glucose to citrus fruit-derived flavonoid component Naringin with the power of enzymes, for improved water solubility allowing it to be used in cosmetics, etc. It is a new ingredient that promotes density in the skin’s elastin network, which serves to support collagen fibers, and increases skin’s firmness and elasticity

In addition to mitsumata, Naito wanted to use local ingredients connected to Okayama as much as possible while developing his products, so he chose Nagase Viita ingredients.

The AA2G™(Ascorbyl Glucoside) contained in the serum is a vitamin C derivative featuring Nagase Viita enzymatic technology that stabilizes easily changeable vitamin C by binding it to glucose. With a proven record as an active ingredient in quasi-drugs, this ingredient inhibits melanin production to reduce age spots and freckles.

The Glucosyl Naringin used in the lift lotion binds glucose to citrus fruit-derived flavonoid component Naringin with the power of enzymes, for improved water solubility allowing it to be used in cosmetics, etc. It is a new ingredient that promotes density in the skin’s elastin network, which serves to support collagen fibers, and increases skin’s firmness and elasticity

Bringing a sustainable viewpoint to the cosmetics industry

(Right) The Gold Medal awarded to Hayashibara (Nagase Viita at present) by EcoVadis

Glucosyl Naringin is made from citrus fruits that are picked early or fall during cultivation. Nagase Viita upsycles (give new and improved value to) fruit that won’t be used as food into cosmetic ingredients, reducing disposal waste. And with AA2G™, we make effective use of the nutritionally rich by-products released during the manufacturing process, contributing to reducing the environmental burden of disposal.

In recent years, cosmetic product manufacturers have grown increasingly conscious of creating ethical products that are kind to both people and the planet. And similarly, Nagase Viita seriously considers the environment and human rights during development and manufacturing of the cosmetic ingredients that we supply. Our initiatives earned praise and received a Gold rating, denoting the top 5% of companies, from French sustainability evaluation body EcoVadis in their 2022 survey.

Yunoka may be a new brand just recently created in Maniwa, but the sincere community spirit that inspired it really touches people’s hearts. And at Nagase Viita, we also want to continue supporting products with that spirit as a trustworthy supplier.

In recent years, cosmetic product manufacturers have grown increasingly conscious of creating ethical products that are kind to both people and the planet. And similarly, Nagase Viita seriously considers the environment and human rights during development and manufacturing of the cosmetic ingredients that we supply. Our initiatives earned praise and received a Gold rating, denoting the top 5% of companies, from French sustainability evaluation body EcoVadis in their 2022 survey.

Yunoka may be a new brand just recently created in Maniwa, but the sincere community spirit that inspired it really touches people’s hearts. And at Nagase Viita, we also want to continue supporting products with that spirit as a trustworthy supplier.

- ■Official brand website for Yunoka (Japanese):https://www.yunokapj.jp/

YUNOKA Co., Ltd.

YUNOKA Co., Ltd.

- Nagase Viita’s Sustainability Focus Points:

- ●Highlights the new value of local resource mitsumata as a cosmetic ingredient and commercializes it to contribute to community revitalization

- ●Uses locally grown mitsumata as an ingredient to support a revival of mitsumata cultivation

- ●Uses locally produced Japanese paper packaging to support local traditional manufacturing and the culture of Japanese traditional paper making