Sustainable Stories

10story

2025.03.26

Supporting Sudan from Okayama Across the SeasMaking a Global Impact with a Small-Town Factory's Food Dryer

Top Food Dryer Manufacturer in the Japanese Market

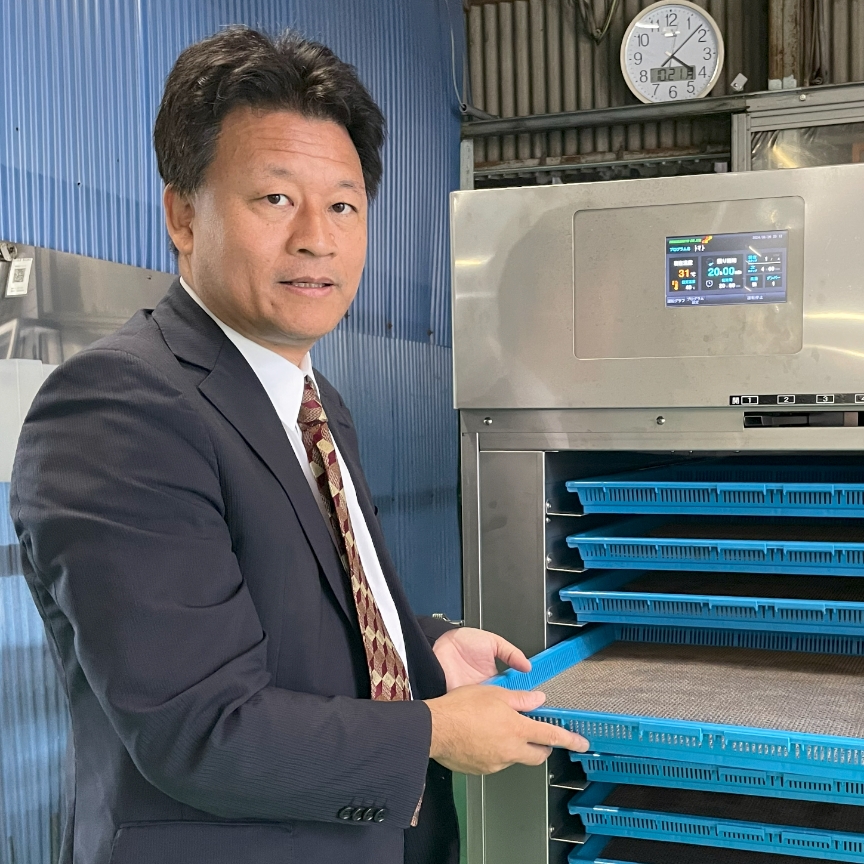

Located in Kita Ward of Okayama City, Taiki Sangyo Co., Ltd. is a specialist manufacturer of food dryers, with its headquarters and factory in the region. Since its founding in 1948, the company initially concentrated on producing kerosene dryers for tobacco leaves before shifting its focus to food dryers. In 2008, a year after Soichiro Yasuhara stepped up as the third-generation president, Taiki Sangyo launched the industry’s first electric food dryer.

The company later developed a new model that is safe, economical, and compatible with household power outlets. This advancement significantly enhanced the production of dried fruits and vegetable chips. It also supports value-added agriculture, allowing farmers to turn their produce into marketable products. Today, Taiki Sangyo holds the largest market share in Japan’s food dehydrator sector and boasts large industrial models that remain unmatched globally.

Product Potential Met with Sudan’s Needs

The development of the electric dryer represented a significant expansion opportunity for the company. Since kerosene quality varies by country, leading to potential malfunctions in kerosene-fueled machines, the shift to electricity provides a distinct advantage. Users can easily plug in the machine, which reduces maintenance needs and minimizes breakdowns, making it highly suitable for the international market. Initially leveraging installations in overseas factories of Japanese food manufacturers, the company has expanded its distribution from Southeast Asia, including Vietnam and Indonesia, to Africa and the Americas.

At that time, a consultant assisting with the company's international business development approached Mr. Yasuhara with a proposal. ”Why not explore Sudan? The needs of Sudan and your technology and products are a perfect match,” he suggested.

In the Republic of Sudan, located in Northeast Africa, onions are a staple crop, and dried onions, which are highly preservable, are widely used in home cooking. However, the unstable political situation forced the shutdown of industrial onion-drying facilities. This disruption resulted in a glut of fresh produce on the market, causing onion prices to plummet and forcing farmers to abandon their produce. Additionally, in the hot and humid environment without adequate refrigeration, unused produce spoiled in fields and markets, contributing to significant food loss.

To address these challenges, there was a demand for food dehydrators that farmers could operate. Given Sudan's access to affordable electricity thanks to abundant hydroelectric power, electric dryers became preferred over kerosene-fueled models. Taiki Sangyo is the only company in Japan capable of providing large electric dryers that can operate seamlessly in Africa’s harsh conditions and are easy for anyone to handle safely. Recognized for this unique technology, the company was encouraged to apply for a support project led by JICA (Japan International Cooperation Agency).

As president, Mr. Yasuhara had long desired to expand further into international markets and make a global impact. The JICA project was perfectly aligned with these aspirations, offering a real opportunity to fulfill these goals.

However, Sudan has unstable political conditions ruled by the military. Traveling there from Japan alone involves considerable effort, and it's uncertain whether the business will be sustainable in the long term. Understandably, there were voices of concern within the company about pursuing this venture.

Although there were concerns, President Yasuhara remained committed. "Yet, this is something only we can do. Despite the uncertainties, I decided that we must take on this challenge. After all, our success with the electric food dryer came from venturing into uncharted territory," he explains.

Journey to Sudan with the Product: Demonstrating Its True Value On-Site

The first project, launched in 2015, began with a survey to assess local needs. "However, I didn't think that simply going there and promoting the benefits of our food dryers would be enough, as words alone cannot fully convey our commitment. I believed that demonstrating the machines in actual use would better represent our earnest approach," Mr. Yasuhara noted. Accordingly, the company shipped the latest electric dryer to Sudan and installed it at its own expense.

When we conducted a demonstration of the machine on-site, a large crowd of locals gathered, eager to see the Japanese machine. "Everyone was inquisitive, and I felt a tremendous eagerness. People from the neighborhood, not directly involved in the operations, also joined in, asking various questions and creating a lively atmosphere," he recalled.

The locally sold sun-dried onions were brownish, scorched by UV rays, and gritty with sand. In contrast, the onions dried in the electric dryer were pure white and seemed as fresh as they had been prepared minutes ago. The product's superiority was immediately apparent to the locals, who enthusiastically endorsed its marketability.

Building Cooperatives for Independent Income Among Female Farmers

After confirming the local acceptance of its dryer, the company decided to proceed to the next phase in 2018.

The new venture involved setting up small-scale cooperatives organized by local female farmers, enabling each cooperative to manufacture and sell dried onions. This initiative draws inspiration from a successful approach in Japan, where female farmers used dryers to commercialize their agricultural products effectively.

The unemployment rate among Sudanese women is notably high, with nearly half of the younger generation unable to find jobs. By introducing an equipment package that includes electric dryers, slicers, and packaging machines, women who may not be suited for physically demanding labor can now manufacture dried onions themselves. This setup enables them to produce their goods and earn income by selling them.

"Sudan is a predominantly Islamic country, where women tend to be less visible in public forums. Men typically sit in the front, while women sit on mats at the back at our workshops. Their cultural norms make it challenging to casually converse with the women who would directly use the machines. However, their involvement became active and vibrant once the cooperatives were established. They even developed original recipes to make the products more appealing to buyers, demonstrating a strong desire to sustain their businesses," Mr. Yasuhara recounts his experiences in Sudan.

In addition to the JICA project, the company has also participated in the Japan’s ODA (Official Development Assistance) program hosted by the Ministry of Foreign Affairs of Japan, introducing over 30 electric dryers to Sudan. These efforts have reduced the waste of fresh onions while increasing farmers' incomes and supporting women's employment.

This initiative has led to the spread of the dryers into other African countries, including Botswana and Malawi, further enlarging the company's overseas market presence. Mr. Yasuhara comments, "The fact that our machines have been operating without issues in Africa's unforgiving climate for over five years is a testament to their durability and ease of maintenance, which has visibly boosted our credibility." The company serves clients worldwide, delivering products to over 30 countries.

Enhancing Value and Utilizing Non-Standard Agricultural Produce

Needless to say, the company's food dryers are also making significant contributions within Japan. Traditionally, many dried fruits were imported, but these dryers have made it possible to produce high-quality dried fruits using fresh, locally produced fruits. A major appeal is the ability to effectively utilize fruits and vegetables that are slightly damaged or oddly shaped, which would otherwise not meet commercial standards. For instance, creating high-value products such as macarons infused with dried vegetable powder or bread loaded with large raisins from Okayama Pione grapes has become feasible. This innovation has led to widespread adoption by agricultural corporations, bakeries, and major food manufacturers.

Nagase Viita has been part of these marketing efforts. Collaborating with Taiki Sangyo, the product application development section, "L'Plaza," has developed recipes for dried fruits using trehalose. Taiki Sangyo then uses these as samples during presentations to potential customers.

"Showing a catalog is one thing, but having people taste the product to verify its outcome is far more persuasive," Mr. Yasuhara explains with a smile. "By showcasing the combined benefits of trehalose, which enhances the quality of sweets, and the capabilities of our food dryers, we can present a compelling case that highlights the synergistic effects of both."

How a Small Regional Company Succeeded in Tackling a World-Class Challenge

Recognized for its efforts in Sudan, the company received the "Okayama SDGs Award 2021 for Outstanding Initiatives" and the "Innovation in Manufacturing and Services Expo 2023 SDGs Award for Excellence." Increased media coverage has not only raised the company's profile but has also led to more inquiries and enhanced awareness within the company of the global impact of its products.

Additionally, the company has received numerous requests for lectures and tours, particularly for educational programs focused on the SDGs. "Even a small company from our hometown of Okayama can make a significant social impact as far away as Africa with our unique products. I want to convey this to the younger generation," says Mr. Yasuhara. Despite his busy schedule, he actively responds to these requests.

Nagase Viita will continue to support Taiki Sangyo through collaborative efforts by providing technical advice such as formulation development.

Taiki Sangyo Co., Ltd.

Taiki Sangyo Co., Ltd.

- Nagase Viita's Sustainability Focus Points:

- ● Utilizes unique product features to reduce food loss in Africa and Southeast Asia, improving income in impoverished rural areas and promoting women's employment.

- ● Bolsters agricultural diversification by repurposing non-standard agricultural products and turning them into value-added goods.

- ● Advances SDG initiatives in the company's hometown of Okayama, actively engaging local communities through lectures and factory tours.