Sustainable Stories

Nagase Viita's WEB Magazine

07story

December 20, 2023

The Trehalose Application in an Unexplored Area: Conserving Buried Cultural Properties for the Future

Trehalose, primarily known for its exceptional functionality in food, pharmaceuticals, and personal care products, is now expanding into a unique field: cultural property conservation.

Since research began in 2008, this trehalose-based approach has proven highly effective in conserving precious historical materials for future generations.

Since research began in 2008, this trehalose-based approach has proven highly effective in conserving precious historical materials for future generations.

Photo courtesy of the Matsuura City Board of Education (right: anchor impregnation treatment)

Precious Archaeological Objects Found Under Ground and in the Water

Wood objects, such as ships, containers, and farming tools, are often excavated from soils and underwater sites.

While they normally decay over the years, these objects can sometimes remain intact for centuries, even millennia. This state of conservation is largely due to environments with high moisture and low oxygen levels, where microbial activity that typically decomposes wood is halted.

While these objects retain their shape, their wooden components often decompose or leach out, leading to excessive moisture absorption. Carelessly drying after excavation can cause severe shrinkage, damaging their shape.

Extensive research on conservation techniques for wood objects (waterlogged wood objects) has been carried out worldwide. The predominant method globally has been the polyethylene glycol impregnation method, commonly called the "PEG method." This involves reinforcing wood objects by soaking them in a polyethylene glycol (PEG) solution.

However, the PEG method, involving a time-consuming impregnation process, presents challenges, including potential deformation of objects. Additionally, in hot and humid environments, the PEG substance may leach out of the treated objects.

While they normally decay over the years, these objects can sometimes remain intact for centuries, even millennia. This state of conservation is largely due to environments with high moisture and low oxygen levels, where microbial activity that typically decomposes wood is halted.

While these objects retain their shape, their wooden components often decompose or leach out, leading to excessive moisture absorption. Carelessly drying after excavation can cause severe shrinkage, damaging their shape.

Extensive research on conservation techniques for wood objects (waterlogged wood objects) has been carried out worldwide. The predominant method globally has been the polyethylene glycol impregnation method, commonly called the "PEG method." This involves reinforcing wood objects by soaking them in a polyethylene glycol (PEG) solution.

However, the PEG method, involving a time-consuming impregnation process, presents challenges, including potential deformation of objects. Additionally, in hot and humid environments, the PEG substance may leach out of the treated objects.

(Photo courtesy of Prof. Koji Ito)

Seeking solutions, Prof. Setsuo Imazu, then with the Archaeological Institute of Kashihara in Nara Prefecture and now Nara University's President, started researching a sugar-based impregnation method.

Prof. Koji Ito of the Institute for Conservation of Cultural Property at Tohoku University of Art & Design, whom we interviewed for this article, was captivated by this approach and subsequently joined the research efforts.

Improving Treatment Methods with Sugars

At that time, Prof. Ito belonged to the Osaka City Cultural Properties Association, researching techniques for conserving buried cultural objects. Prof. Imazu and Ito, who had joined the project, first tackled a method involving impregnating objects with lactitol, a type of sugar alcohol.

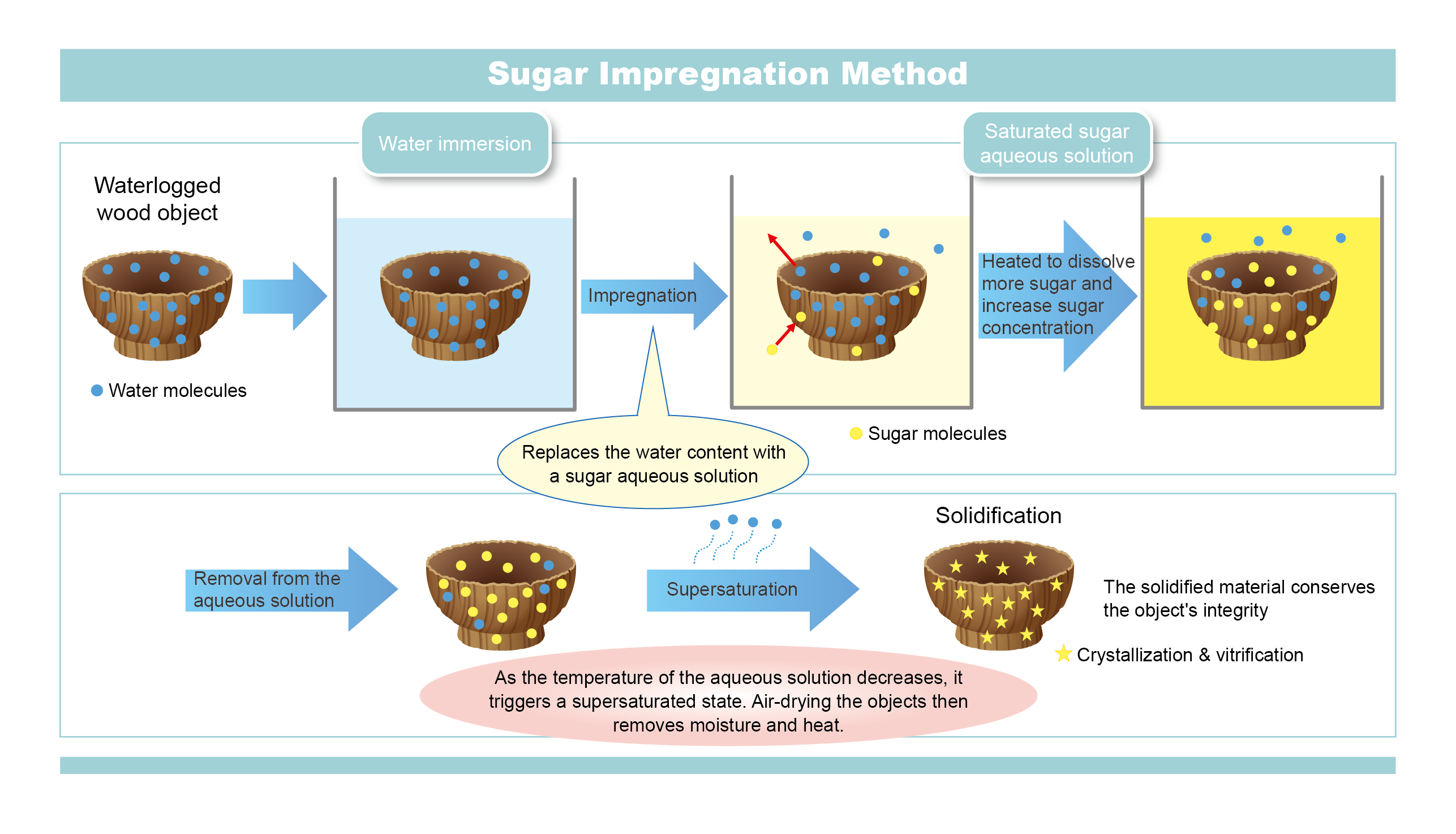

In the sugar impregnation, objects are immersed in a sugar aqueous solution. This solution is heated to increase the solubility of sugar. This allows for the dissolution of more sugar, increasing its concentration and enabling thorough penetration into the interior of the wood. When the object is removed from the sugar aqueous solution, the sugar solidifies due to a supersaturated state as the temperature drops. Finally, the object is air-dried to evaporate the water, concentrating and solidifying the residual sugar solution.

In the sugar impregnation, objects are immersed in a sugar aqueous solution. This solution is heated to increase the solubility of sugar. This allows for the dissolution of more sugar, increasing its concentration and enabling thorough penetration into the interior of the wood. When the object is removed from the sugar aqueous solution, the sugar solidifies due to a supersaturated state as the temperature drops. Finally, the object is air-dried to evaporate the water, concentrating and solidifying the residual sugar solution.

With its small molecular weight and ease of penetration, lactitol was a highly effective alternative to PEG, but this was also not without imperfections.

Prof. Ito explains, "If crystalized properly, lactitol can maintain objects in a very stable state of conservation. Achieving proper crystallization is key since inappropriate crystal formation can lead to damage or destruction of the objects."

Lactitol has four crystalline forms, influenced by crystallization conditions like concentration and temperature. Successfully conserving objects requires appropriate crystalline, as each type has different properties. However, achieving this involves precise control over factors beyond concentration and temperature. This level of detail makes the process challenging, often leading to errors, particularly for those less experienced.

Prof. Ito explains, "If crystalized properly, lactitol can maintain objects in a very stable state of conservation. Achieving proper crystallization is key since inappropriate crystal formation can lead to damage or destruction of the objects."

Lactitol has four crystalline forms, influenced by crystallization conditions like concentration and temperature. Successfully conserving objects requires appropriate crystalline, as each type has different properties. However, achieving this involves precise control over factors beyond concentration and temperature. This level of detail makes the process challenging, often leading to errors, particularly for those less experienced.

Trehalose Provides Solutions for Complex Needs

Research on methods using trehalose began in 2008.

When Prof. Imazu began his research on the sugar methods in the early 1990s, trehalose was originally a candidate for the main ingredient. However, because trehalose was very expensive then, lactitol was selected as a substitute.

In 1995, Nagase Viita's (formerly Hayashibara) success in the industrial production of trehalose led to a significant reduction in its cost, about one-hundredth of its original price, making it more accessible. This and the instability in lactitol supply brought trehalose back into the spotlight.

When Prof. Imazu began his research on the sugar methods in the early 1990s, trehalose was originally a candidate for the main ingredient. However, because trehalose was very expensive then, lactitol was selected as a substitute.

In 1995, Nagase Viita's (formerly Hayashibara) success in the industrial production of trehalose led to a significant reduction in its cost, about one-hundredth of its original price, making it more accessible. This and the instability in lactitol supply brought trehalose back into the spotlight.

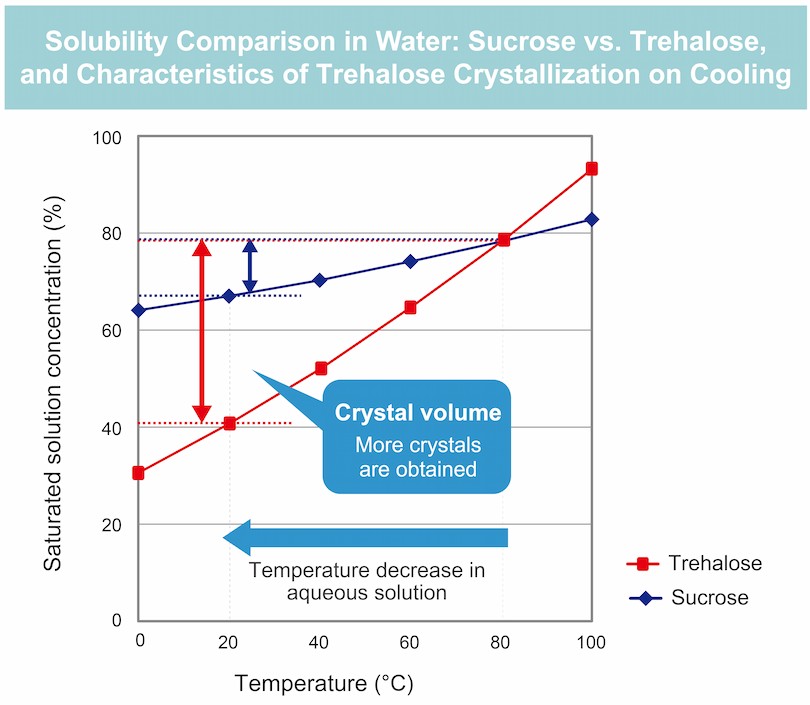

With its superior resistance to acid and heat over lactitol, trehalose remains stable, even in acidified, high-temperature impregnating solutions. Another key advantage is its significant increase in solubility with rising aqueous solution temperature, which allows for a higher yield of crystals when the temperature is subsequently lowered.

Trehalose crystals have very low hygroscopicity and can be easily stored after conservation treatment, even in hot and humid regions such as Japan.

The trehalose impregnation method allows treatment at lower concentrations for objects with minimal deterioration. Additionally, the solidification approach can be tailored to the objects's condition. For instance, objects like textiles, where retaining the original color is important, can be solidified in a "glass" state, offering higher transparency than a crystal form.

Thanks to these benefits, the scope of conservable objects that can be effectively conserved has significantly broadened to encompass delicate materials like cloth, rope, and lacquerware.

In the case of wood-iron composite materials, such as those with attached nails, the PEG method often leads to iron corrosion due to moisture absorption, causing damage to the surrounding wood after the conservation process. The trehalose impregnation method, however, utilizes its unique properties to prevent such corrosion of iron.

Nagase Viita researchers, highly knowledgeable about the properties of trehalose, provided guidance and advice on the crystallization/vitrification mechanism during this research.

Conservation Project of Bulkhead Plank of Sunken Mongolian Warship

The excavated object is a bulkhead plank, a partition board from within a ship that sank during the Mongolian invasion. The Mongolian invasion was a historical event in the Kamakura period (1185-1333) when Yuan fleets invaded Japan in 1274 and 1281.

Takashima Island (Takashima-cho, Matsuura City, Nagasaki Prefecture), located in Imari Bay, is an ancient battlefield of the Mongolian invasion, and many objects of the Mongolian invasion remain submerged on the surrounding seabed.

The bulkhead plank, a large wooden plank measuring approximately 5.6 meters long and weighing around 364 kg, was raised from the seasite in 2002. Since then, it has been stored in tap water at the Matsuura City Archaeological Center for 17 years.

Prof. Ito first fabricated a large impregnation tank to accommodate this bulkhead plank. He filled the impregnation tank with a trehalose solution and submerged the plank, warming the solution to 60-80°C and allowing it to permeate slowly over about two years.

Trehalose allowed the impregnation process to be completed in less than half the time compared to the conventional method. The bulkhead plank was removed in March 2021, and after several months of solidification and drying, a surface treatment was applied to complete the conservation process. Yumi Yasuki of the Matsuura City Archaeological Center worked on the project continuously for two years.

▲Impregnation in process (left) and bulkhead plank after completion of conservation process (right) (photo courtesy of the Matsuura City Board of Education)

▲Impregnation in process (left) and bulkhead plank after completion of conservation process (right) (photo courtesy of the Matsuura City Board of Education)

The Importance of Low-Cost and Simple Conservation Methods

During the impregnation process, huge costs are incurred for heating the sugar-aqueous solution with an electric heater for a long time. Beyond financial considerations, the environmental impact is also a substantial concern. There is a pressing demand for conservation methods that can be practiced in various parts of the world where electricity and fuel supplies are unreliable.

Therefore, a significant focus during the conservation of the bulkhead plank was on achieving favorable outcomes without substantial costs or environmental burdens.

Therefore, a significant focus during the conservation of the bulkhead plank was on achieving favorable outcomes without substantial costs or environmental burdens.

Prof. Ito is exploring additional techniques, such as impregnating objects by dripping trehalose aqueous solution directly onto them without using large tanks and recycling and reusing spent solutions. He remains constantly alert for inspiration from everyday occurrences, aiming to develop conservation methods that are more affordable, eco-friendly, and straightforward.

Prof. Ito states, "Conservation processes should not require specialized skills. My goal is to develop a method that is accessible and straightforward for anyone, anywhere, with a low risk of failure so we can conserve as much of the hidden cultural properties around the globe as possible. This is the purpose behind my research."

Conserving the precious objects left by our ancestors is a mission shared globally, aimed at future generations. Nagase Viita is committed to furthering this goal by continuing to support research and aid in the conservation of cultural properties, through the development and production of functional materials like trehalose.

Conservation techniques using trehalose for cultural properties are extending their reach.

The Matsuura City Archaeological Center is currently working on conserving a "single stone stock wooden anchor" from the Mongolian invasion shipwreck, which was raised from the Takashima underwater site in October 2022. The conservation process is expected to be finished by the fall of 2025.

Additionally, in Nagaoka City, Niigata Prefecture, the iron shaft of the Jundomaru, a paddle steamer owned by the Edo Shogunate at the end of the Edo period (a designated cultural property of Nagaoka City), was being treated with trehalose under the guidance of Prof. Ito. This is the first time that the trehalose impregnation method has been used for the conservation of a large metal object salvaged from the seabed, and there have already been requests for guidance from overseas.

Prof. Koji Ito conducted technical training on the trehalose impregnation method during a workshop held by UNESCO on October 27-28, 2023. For further details, refer to The press release* issued by Tohoku University of Art & Design.

Conservation of Buried Cultural Properties Using Trehalose

Conservation of Buried Cultural Properties Using Trehalose

- Sustainability Initiatives:

- ● Sugar impregnation techniques overcome the long processing times of the PEG method.

- ● The conservation process with trehalose is more adaptable and straightforward compared to existing techniques such as the PEG Method and sugar alcohol applications. It can cover a broader range of objects, helping to protect a greater number of cultural properties for future generations.

- ● Trehalose, often used for food processing, enables conservation treatments to be conducted safely and securely.

- ● Trehalose is very stable in its crystal and glass states, which prevent objects from deteriorating after conservation. This stability eases the burden and costs associated with storing and displaying these items.