Manufacturing Utilizing Microorganisms

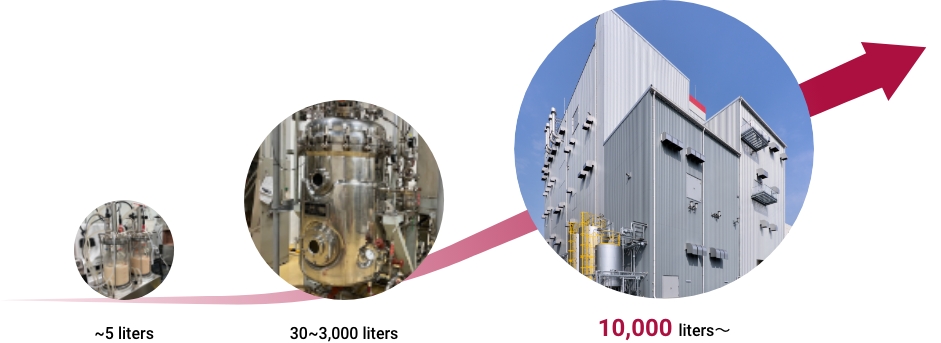

Using microbiology and cultivation expertise to transform processes from "lab-made" to "mass-produced."

Microorganism growth is influenced by a variety of environmental factors, including nutrient availability, oxygen supply, and temperature.

Cultivating in test tubes and tanks of several thousand liters cannot be done in the same way.

We use accumulated cultivation experience and data to seamlessly transition microorganisms discovered during initial research through the manufacturing process technology development department, resulting in effective cultivation scale-up and product delivery to the world.

Precision Design of Microorganisms for Seamless Implementation

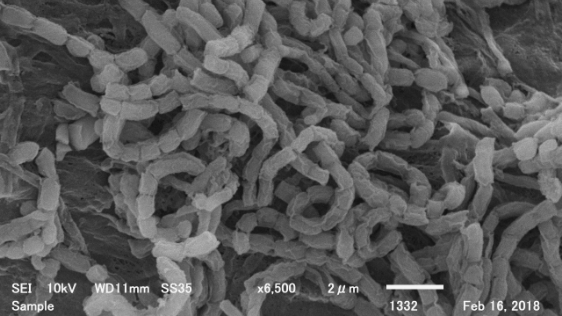

With years of experience with actinomycetes, we have developed an in-house technology known as N-STePP® (NAGASE's Streptomyces technology for Precious Products), which allows for the free expression of enzymes derived from the Streptomyces genus of actinomycetes.

Using this technology, we can introduce new enzymatic products to the market every one to two years by utilizing microbes suitable for industrial manufacturing and developing cultivation processes that use these microorganisms.

Based on our exclusive library, we also have a collection of enzymes that have already met regulatory requirements (please refer to the table below).

We have not only laboratory R&D knowledge, but also regulatory compliance expertise, which is essential for bringing products to market.

Unique enzyme libraries which comply with Japanese food regulations

| Production strain | |

|---|---|

| phospholipase D | S.violaceoruber pTOMO11 |

| phospholipase A2 | S.violaceoruber AS-10 |

| chitinase | S.violaceoruber pNAG |

| chitinase | S.violaceoruber pCHI |

| glucanase | S.violaceoruber pGlu |

| protease | S.violaceoruber pCol |

| phospholipase | S.violaceoruber pLPL |

| phospholipase | S.violaceoruber pPDN |

| peptidase | S.violaceoruber pSSA |

| peptidase | S.violaceoruber pXPO |

| chitinase | S.violaceoruber pCHC |

| phospholipase | S.violaceoruber pPDX |

| Production strain | |

|---|---|

| phospholipase | S.violaceoruber pLPL |

| phospholipase | S.violaceoruber pPDN |

| peptidase | S.violaceoruber pSSA |

| peptidase | S.violaceoruber pXPO |

| chitinase | S.violaceoruber pCHC |

| phospholipase | S.violaceoruber pPDX |

(Provided by Dr. Hideki Yamamura, University of Yamanashi)

From Mixtures of Components to High-Purity Products

The liquid produced by microorganism cultivation or enzymatic reactions contains a variety of components.

We are committed to purifying and extracting the desired substances, bringing high-purity products to the world.

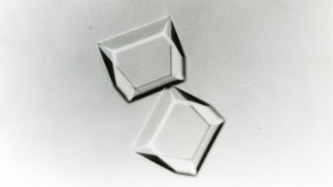

In this process, we use crystallization control techniques that have been honed with sugars and sugar derivatives, with the goal of achieving high recovery rates and designing waste-minimizing processes.

Recommended Content

Exploring Useful Substances from Nature

Discovering new enzymes from natural samples such as soil.

Formulation Design Utilizing Ingredients

We conduct prototyping of food and personal care products to ensure that differences can be felt by people before quantifying product characteristics using instrumental analysis and developing theories about their mechanisms of action.

Functional Verification of Materials with Respect to Living Organisms

By investigating the effects of materials on living organisms, we can ensure their safety and create new value that promotes healthy lifestyles.

Quality and Safety

We see our responsibility as being two-fold: firstly, we have a responsibility for the safety and quality of our products, and we also have a responsibility to contribute to making society a place where everyone is safe and can live a healthy life.

Inquiries

Please contact us if you have any questions for details about proprietary technologies.

Contact Us