From Starch Syrup

to Scientific Discovery

Redefining Saccharide Science

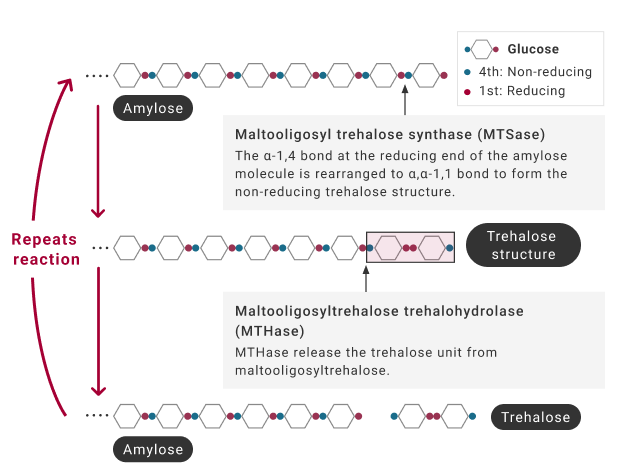

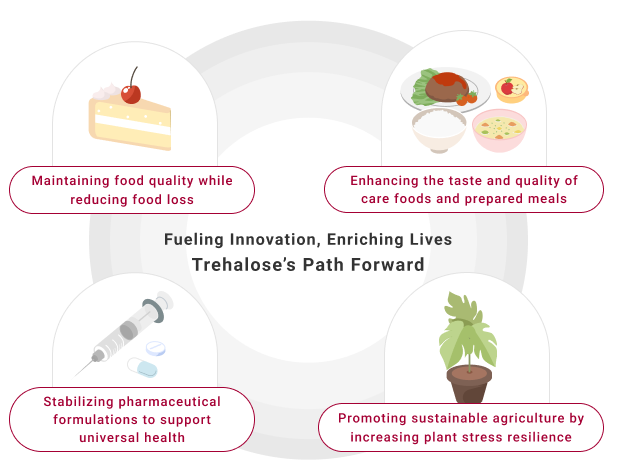

Nagase Viita traces its roots back to 1883 as a starch syrup producer. Over generations, the company built deep expertise in carbohydrate research, developing enzymatic methods to transform starch into valuable saccharides like glucose and maltose.

By the 1980s, nearly all commercially viable saccharides and sweeteners had already been industrialized, and the idea of creating entirely new sugars from starch was widely regarded as impossible. Yet, guided by the philosophy “Create what has never been done by challenging what others will not,” Nagase Viita researchers set out to break this barrier—ushering in one of the most important advances in carbohydrate biotransformation.