Nikkei Online Advertising Feature

30 Years of Trehalose Innovation

A Sweet Partnership with Tradition

Executive Director of

Japan Wagashi Association

Mitsuo Yabu

President of

Nagase Viita

Takahiko Mandai

Thirty years after Nagase Viita (formerly Hayashibara) first succeeded in mass-producing trehalose, TREHA™, the rare sugar has become a quiet but indispensable ingredient across Japan’s traditional confectionery sector. What began as a breakthrough in enzyme technology has grown into a long-running partnership between industrial science and artisanship—one that continues to influence how wagashi is made, distributed, and enjoyed.

To mark the anniversary, Nagase Viita President Takahiko Mandai and Japan Wagashi Association Executive Director Mitsuo Yabu spoke about trehalose’s origins, its impact on century-old confectionery practices, and what the future may hold for the ingredient.

From Rare Commodity

to Everyday Ingredient

Trehalose(TREHA™)occurs naturally in mushrooms, plants, and microorganisms, but extracting it at scale was once extremely expensive. Before 1995, the cost could reach tens of thousands of yen per kilogram. “Our discovery enabled trehalose production from starch, bringing the cost down to one - hundredth of its original level,” Mandai explains. “That shift made it possible for the ingredient to enter mainstream markets.”

While trehalose is now widely used in food, personal care, and pharmaceuticals, its earliest and most enthusiastic adopters emerged from the craftsmen of wagashi, Japan’s traditional sweets.

“Wagashi makers gave us invaluable feedback in the beginning,” Mandai says. “In many ways, their support shaped how trehalose developed as an ingredient and for that I’d like to express my heartfelt gratitude.”

A Skeptical Start Gives Way to Widespread Adoption

“At first, I honestly thought trehalose would ruin wagashi,” Yabu says with a laugh. “It was marketed as a ‘low-sweetness sweetener’ at a time when people were cutting back on sugar. But to me, sweetness is essential to wagashi. Reducing it felt wrong.”

Mitsuo Yabu

Executive Director of

Japan Wagashi Association

His skepticism softened only when he began experimenting with the ingredient himself, a hands-on approach many artisans shared. The more he tested, the more impressed he became.

“I read the materials brought by Nagase Viita’s executives—6 centimeters thick, but ultimately the real understanding came from trying it myself,” he explains. “As I experimented, I saw the benefits clearly: moisture retention, heat stability, and the ability to slow starch aging. Trehalose didn’t diminish wagashi—it enhanced it.”

Why Moisture Control Matters in Wagashi

Wagashi may look simple, but it is built on delicate chemistry. Small shifts in moisture, temperature, and starch behavior can dramatically change texture and flavor. That’s where trehalose quietly excelled.

“Of all its characteristics, its ability to retain moisture is the most impressive,” Yabu explains. “Sugar does this too, but trehalose does it better.”

Take monaka—a crisp wafer filled with sweet bean paste. Any excess moisture causes the shell to soften quickly, so confectioners traditionally add syrup or sugar to control water migration. But that also increases sweetness.

“Trehalose keeps the filling moist without oversweetening,” Yabu says. “You get a crisp shell and a balanced flavor. That was a big moment of realization for us.”

Trehalose also stabilizes texture, resists heat and acidity, slows starch retrogradation, and prevents undesirable crystallization—all critical in handcrafted wagashi.

Finding the “Golden Point”

Through Collaboration

Perfecting the proper amount of trehalose was an early challenge. Too little had no effect; too much caused crystallization or off-textures.

“At our application lab, L’Plaza, our researchers worked closely with wagashi artisans to figure out the optimal amount—the ‘golden point,’ ” Mandai says. “It was true trial-and-error innovation, done side by side.”

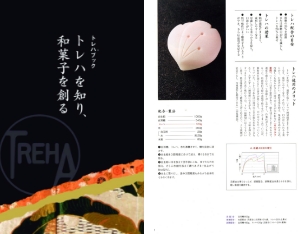

This collaboration culminated in the 2011 publication of The TREHA™ BOOK, co-created by Yabu and leading wagashi artisans from across Japan. The book categorized trehalose’s functional properties and offered scientifically validated recipes and bridged the gap between intuition and science.

“For artisans who have relied on inherited knowledge for generations, it was meaningful to explore wagashi from a scientific viewpoint,” Yabu says. “The data confirmed what many had sensed intuitively and gave younger confectioners a foundation for experimenting with confidence.”

The Unsung “Supporting Player” Behind Modern Wagashi

Trehalose’s appeal lies in its ability to complement—rather than replace—traditional ingredients. Known among artisans as a “supporting player,” trehalose enhances texture, stability, and moisture control without altering the core flavor profile.

In egg-based sweets, trehalose produces finer, more stable meringues. In mochi (rice cakes), it slows starch retrogradation, allowing products to remain soft longer and withstand freezing and thawing. These functional benefits have expanded distribution possibilities for wagashi, particularly outside major urban centers.

“Extended shelf life improves not only product quality but also reduces food waste,” Mandai notes. “This aligns well with broader sustainability goals.”

Today, Yabu estimates that more than 90% of wagashi makers use trehalose in some form. Adoption in Western-style confectionery, however, remains limited.

“I often introduce trehalose to chefs when I visit restaurants,” Yabu says. “There is still enormous potential outside the wagashi world.”

Takahiko Mandai

President of Nagase Viita

Looking Forward

Tradition, Innovation, and Health

As trehalose enters its fourth decade, both men see new opportunities on the horizon.

“Some consumers avoid trehalose because it is categorized as a food additive, even though it is naturally present in foods like bread and yeast,” Yabu says. “There is room to increase public understanding. TREHA™, the trehalose produced by Nagase Viita, is made from starch. It’s safe and well-regulated.” He also sees demand for reduced-calorie solutions. “If there were a sugar with fewer calories but the same sweetness, it would help people who must limit sweets for health reasons enjoy wagashi again.”

Mandai sees such challenges as an invitation for continued innovation. “Our early work with wagashi artisans taught us the value of co-creation. Moving forward, we will continue to explore new possibilities together, building on tradition while embracing scientific advancement.”

A Tradition Strengthened by Technology

What began as a biochemical breakthrough has become an example of how centuries-old craftsmanship and modern food science can evolve together. Trehalose’s story is not only about an ingredient—it is about collaboration across generations and disciplines.

As TREHA™ celebrates 30 years of commercial production, its future seems poised to expand even further—into new industries, new markets, and perhaps even home kitchens worldwide.

One of its greatest achievements is how it helped preserve and elevate one of Japan’s most cherished cultural crafts. Mandai adds, “Our collaboration with the wagashi industry has led to meaningful improvements in quality and consistency, and we will continue experimenting, evolving, and overcoming future challenges together with our customers.”

※Copyright: Nikkei Inc. (2025 Nikkei Online Advertising Feature). Unauthorized reproduction, reprinting, public transmission, etc., of all content including articles, photos, illustrations, etc., is prohibited.