- Isomaltodextrin is a water-soluble dietary fiber with various bioactive functions, including regulating the intestinal microbiome and bowel movement, immunity, and blood glucose. Since isomaltodextrin is colorless and odorless in an aqueous solution, it can be easily formulated in foods, including those with a white appearance such as cooked rice and udon noodles. Because it is odorless it can be used in many foods without interfering with the natural flavor of the foods.

Although research on isomaltodextrin started more than ten years ago it took years to realize its commercial value. The following provides the history and the many challenges that accompanied its journey from development to commercialization.

Bacterial colonies

Bacterial colonies

(photographed on a black paper)

Dietary fiber produced by enzymes

The starting point for the development of isomaltodextrin goes back to 2003. After the launch of trehalose, which is a major product of Nagase Viita (formerly Hayashibara Co., Ltd.) first commercialized in 1995, the company was actively searching for another major product. In response to this, a development goal was established to create a new indigestible polysaccharide (dietary fiber) using Nagase Viita’s expertise in enzyme technology.

For this it was obviously necessary to identify an enzyme or enzymes that could cut the molecular bonds of starch and rearrange them to produce a non-digestible structure. Nagase Viita started the research by collecting soil samples in the same way as for trehalose development. Microorganisms in thousands of soil samples were isolated and carefully examined.

These microorganisms in fluid culture were observed for by-products from their interaction with starch. Any by-products were further observed for interaction with gut digestive enzymes. If a by-product was not decomposed into glucose molecules by the digestive enzymes, the microorganism was assumed to produce an enzyme that transformed starch into indigestive polysaccharides.

For this it was obviously necessary to identify an enzyme or enzymes that could cut the molecular bonds of starch and rearrange them to produce a non-digestible structure. Nagase Viita started the research by collecting soil samples in the same way as for trehalose development. Microorganisms in thousands of soil samples were isolated and carefully examined.

These microorganisms in fluid culture were observed for by-products from their interaction with starch. Any by-products were further observed for interaction with gut digestive enzymes. If a by-product was not decomposed into glucose molecules by the digestive enzymes, the microorganism was assumed to produce an enzyme that transformed starch into indigestive polysaccharides.

Success in mass production

through a long detour

A microorganism with the desired activity was found among the thousands of soil samples. When reacted with starch, the microorganism in the culture solution produced a polysaccharide that was not decomposed by digestive enzymes. It was found that the polysaccharide has a unique structure with many branches. The research team named this polysaccharide "isomaltodextrin" and identified the specific enzyme that produces it in culture.

However, for unknown reasons, the research team was not able to reproduce isomaltodextrin using the same enzyme after many experiments. In addition, this microorganism formed a very viscous solution during cultivation, which was unsuitable for industrial use. For approximately two years, the development team search for a solution for these problems. In 2006, Nagase Viita decided to break the development impasse and replaced the original team with new scientists.

The research was taken over by a different team, to which a researcher, Dr. Hikaru Watanabe belonged. Dr. Watanabe, who had watched the struggles of the previous team, came up with a hypothesis as to why there had been the problems. He speculated that two enzymes maybe needed to produce isomaltodextrin. In fact, trehalose and other sugars also have been shown to require the participation of two enzymes. The new team conducted their research based on his hypothesis.

However, for unknown reasons, the research team was not able to reproduce isomaltodextrin using the same enzyme after many experiments. In addition, this microorganism formed a very viscous solution during cultivation, which was unsuitable for industrial use. For approximately two years, the development team search for a solution for these problems. In 2006, Nagase Viita decided to break the development impasse and replaced the original team with new scientists.

The research was taken over by a different team, to which a researcher, Dr. Hikaru Watanabe belonged. Dr. Watanabe, who had watched the struggles of the previous team, came up with a hypothesis as to why there had been the problems. He speculated that two enzymes maybe needed to produce isomaltodextrin. In fact, trehalose and other sugars also have been shown to require the participation of two enzymes. The new team conducted their research based on his hypothesis.

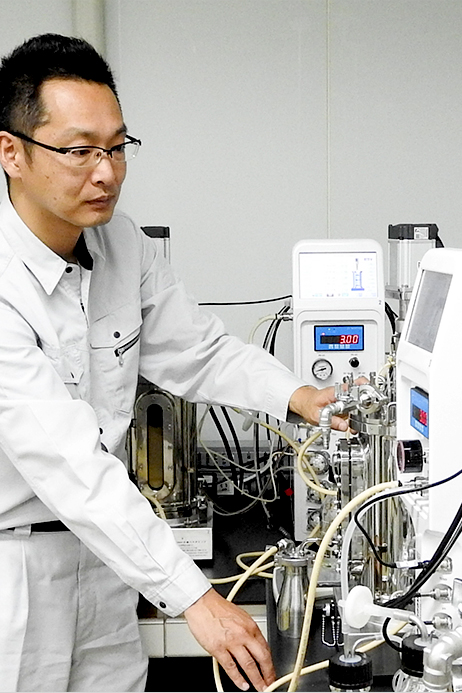

Dr. Hikaru Watanabe, the researcher who discovered

Dr. Hikaru Watanabe, the researcher who discovered

the second enzyme

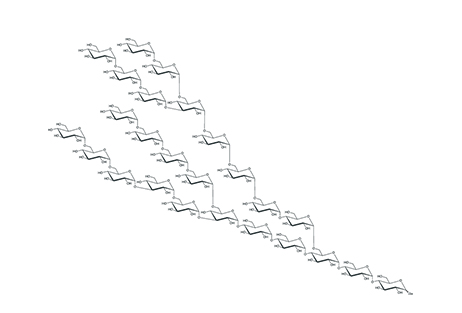

Structural formula of isomaltodextrin

Structural formula of isomaltodextrin Bacteria were proliferated under various conditions, such as

Bacteria were proliferated under various conditions, such as

nutrition and temperature.

Dr. Watanabe discovered that the bacteria actually produce two enzymes during cell proliferation, which acted on the starch and changed it into a substance that is resistant to digestion. However, problems persisted as the bacteria that produced the two enzymes was difficult to use on a production scale due to the highly viscous nature of the solution. The next major step was to search for a bacterium that could produce the two necessary enzymes on without the prohibitive viscosity. Even after a relentless screening process, an alternative bacterium was not identified. This led the team to the determination that the only viable option would be to “reduce the viscous producing nature of the original bacteria".

An expert team within Nagase Viita was formed to optimize the desired properties of the bacteria. Bacteria were proliferated in 100 or more flasks with various conditions including nutrition, temperature, and other parameters. Among the test samples, the bacteria with a less viscous nature were screened for the specific enzyme production. After one year, bacteria that did not create high viscosity was optimized for mass-production.

The improved bacteria contributed to the successful production of isomaltodextrin in a large-scale production process of several hundred kilograms in 2007. The team was now very confident about the launch of isomaltodextrin.

An expert team within Nagase Viita was formed to optimize the desired properties of the bacteria. Bacteria were proliferated in 100 or more flasks with various conditions including nutrition, temperature, and other parameters. Among the test samples, the bacteria with a less viscous nature were screened for the specific enzyme production. After one year, bacteria that did not create high viscosity was optimized for mass-production.

The improved bacteria contributed to the successful production of isomaltodextrin in a large-scale production process of several hundred kilograms in 2007. The team was now very confident about the launch of isomaltodextrin.

Data on physical properties and functionalities were accumulated

Data on physical properties and functionalities were accumulated

point by point.

In need of

more distinctive characteristics

However, even after a few years, isomaltodextrin still remained in the research phase. At that time Nagase Viita employed a system allowing the Research team to work on research of their own choosing, whereas the Product Development team screened materials in the research phase and commercialized the materials that appeared to be marketable. According to the Product Development team, isomaltodextrin was impossible to commercialize without more distinctive characteristics.

Because it is produced by an enzymatic reaction, isomaltodextrin is colorless and odorless compared to other water-soluble dietary fibers manufactured under high heat and acidic conditions. In addition, it has beneficial physical properties such as stability to heat and freeze-thaw cycles. Furthermore, the researchers verified that isomaltodextrin has a number of bioactive functions, such as promoting healthy intestinal environment, blood glucose and blood triglyceride.

Unfortunately, in February 2011 Hayashibara (Nagase Viita at present) applied for the Corporate Reorganization Act, and the research was temporarily suspended.

Because it is produced by an enzymatic reaction, isomaltodextrin is colorless and odorless compared to other water-soluble dietary fibers manufactured under high heat and acidic conditions. In addition, it has beneficial physical properties such as stability to heat and freeze-thaw cycles. Furthermore, the researchers verified that isomaltodextrin has a number of bioactive functions, such as promoting healthy intestinal environment, blood glucose and blood triglyceride.

Unfortunately, in February 2011 Hayashibara (Nagase Viita at present) applied for the Corporate Reorganization Act, and the research was temporarily suspended.

The Company's first cross-departmental

collaboration project

"It was a tough time, but we were grateful that the industry, government, and academia encouraged and supported us during that time," said Dr. Watanabe. Under the supportive environment, the team continued to work on the project. In October 2011, Nagase Viita’s isomaltodextrin was presented at a conference held in the United States. The response was so enthusiastic that the information packets quickly ran out. The result assured Dr. Watanabe that there was a place for isomaltodextrin among the many dietary fiber products on the market.

In February 2012, the corporate reorganization had finally been resolved. Nagase Viita resumed business activities as a subsidiary of Nagase & Co., Ltd. As a symbol of the rebirth and continued vigor of Nagase & Co., Ltd. it was decided that a new product should be launched by the company. Isomaltodextrin was selected to be the product to serve this purpose. It was also a time when the demand for dietary fibers was emerging globally.

After overcoming a big crisis like legal corporate reorganization and being purchased by another company, new hope and a renewed desire to succeed was rising within the company. To harness all the power within the new Nagase Viita all the various departments, that had been separate entities in the past, were integrated. These departments joined together to form the company’s fist cross-departmental project. "Team Isomaltodextrin" was initiated in April 2013.

In February 2012, the corporate reorganization had finally been resolved. Nagase Viita resumed business activities as a subsidiary of Nagase & Co., Ltd. As a symbol of the rebirth and continued vigor of Nagase & Co., Ltd. it was decided that a new product should be launched by the company. Isomaltodextrin was selected to be the product to serve this purpose. It was also a time when the demand for dietary fibers was emerging globally.

After overcoming a big crisis like legal corporate reorganization and being purchased by another company, new hope and a renewed desire to succeed was rising within the company. To harness all the power within the new Nagase Viita all the various departments, that had been separate entities in the past, were integrated. These departments joined together to form the company’s fist cross-departmental project. "Team Isomaltodextrin" was initiated in April 2013.

Project team members

Project team members

As the leader of the project team, Dr. Watanabe managed R&D and oversaw the whole project. Foreseeing the overseas expansion of isomaltodextrin, an international product manager in charge of Nagase Viita products was transferred from Nagase & Co., Ltd. In addition, staff members were recruited from the manufacturing department and from "L’ Plaza" where food applications and recipes are developed. After many years all the pieces for the launch of isomaltodextrin were finally in place.

Nagase Viita hired external institutions to evaluate the effects of isomaltodextrin on health and other supporting data were accumulated. In addition, Nagase Viita obtained a "GRAS" status from the U.S. Food and Drug Administration (FDA), which showed that isomaltodextrin is safe in foods. Nagase Viita made every effort to generate the data needed for isomaltodextrin to be approved throughout the world because of its novel properties.

In 2015, a new water-soluble dietary fiber material, isomaltodextrin, was finally released.

Nagase Viita hired external institutions to evaluate the effects of isomaltodextrin on health and other supporting data were accumulated. In addition, Nagase Viita obtained a "GRAS" status from the U.S. Food and Drug Administration (FDA), which showed that isomaltodextrin is safe in foods. Nagase Viita made every effort to generate the data needed for isomaltodextrin to be approved throughout the world because of its novel properties.

In 2015, a new water-soluble dietary fiber material, isomaltodextrin, was finally released.

Working to develop materials desired by the world

Physiological functions and benefits in formulation appealed to

Physiological functions and benefits in formulation appealed to

audiences at exhibitions

Launching a product is not the only goal of this project. Nagase Viita’s efforts will continue to increase the acceptance of this material and help deliver delicious and healthy foods to people around the world.