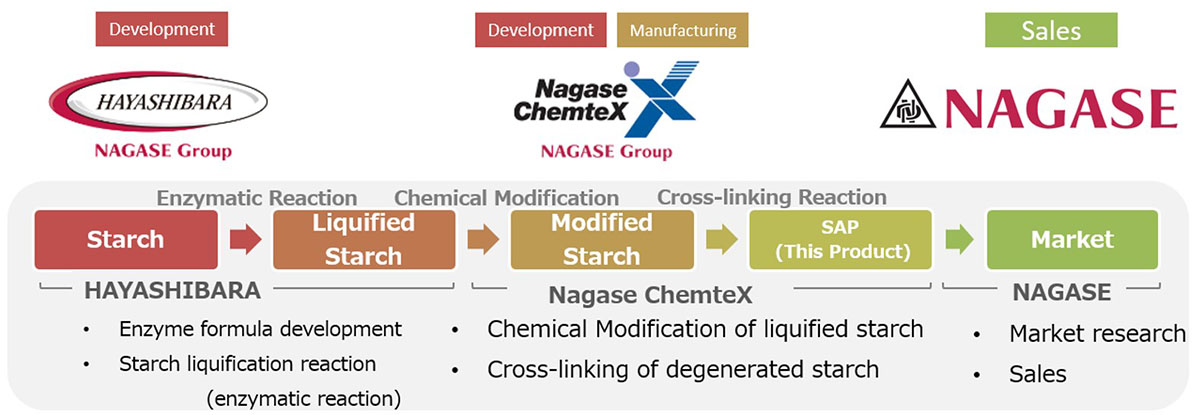

NAGASE & CO., LTD. (Head office: Chiyoda-ku, Tokyo; Representative Director and President: Kenji Asakura) and the NAGASE Group’s core manufacturing company Nagase ChemteX Corporation (Head office: Osaka; President and CEO: Satoru Fujii), along with Hayashibara Co., Ltd. (Head office: Okayama; Representative Director: Naoki Yasuba), have successfully jointly developed a super absorbent polymer (SAP) with absorption properties equal or greater than existing products (*1), while having a high biomass content from an increased proportion of bio-based materials. Aiming for a launch as soon as fiscal 2025, progress is being made on establishing techniques for mass production and building a production system. Nagase ChemteX will handle manufacturing, with NAGASE & CO., LTD. selling the product in Japan and internationally.

SAPs are polymers with high absorbability, and is used in a wide variety of fields, from sanitary products such as paper diapers and pads, to agricultural, greening, and cosmetics products. Most existing SAPs are polyacrylic, with acrylic acid being a main ingredient, and the large environmental burden they have due to being petroleum based and non-biodegradable is an issue. In response, research and development was carried out on biodegradable SAPs with a low environmental burden made from natural materials, using polysaccharides such as starch and cellulose, which are natural polymers, as the primary ingredients, but they did not have sufficient absorbability, and were considered inviable as final products.

The NAGASE Group focused on significantly changing absorption properties through enzymatic conversion of the structure of starch. Combining the enzyme technologies of Hayashibara and the resin manufacturing techniques of Nagase ChemteX, they succeeded in creating an SAP with higher absorbability despite starch being the primary material used.

By contributing to a reduced environmental burden due to being bio-based and biodegradable (*2), this product is planned to be sold to businesses and local governments focusing on developing environmentally-friendly products. It will also be included in solution proposals to create a new sustainable market.

As a biotech company, the NAGASE Group aims to “realize a sustainable world where people live with peace of mind” by contributing to a sustainable society.

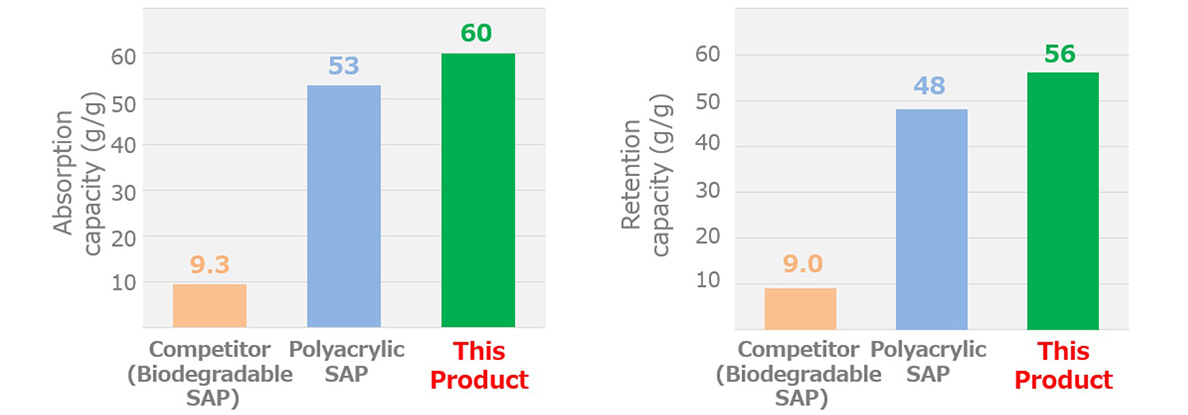

*1: This product was confirmed to have greater absorbability with a saline solution (see Figure 2 below)

*2: The rate of biodegradation varies by grade

■Figure 1: Conceptual Diagram of Joint Development

■Figure 2: Comparison with Competitor’s Biodegradable SAP and Polyacrylic SAP

<Absorbability and Water Retention of Saline Solution>

Absorption capacity: Amount of saline solution (g) absorbed per 1 g of SAP [Based on JIS K 7223-1996]

Retention capacity: Amount retained after dehydrating the SAP with 150 G of centrifugal force for 90 seconds after the absorption test

⇒Compared to both competitor’s SAP and existing polyacrylic SAP, indicated greater absorbability with saline solution

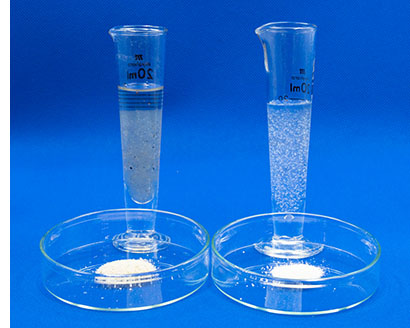

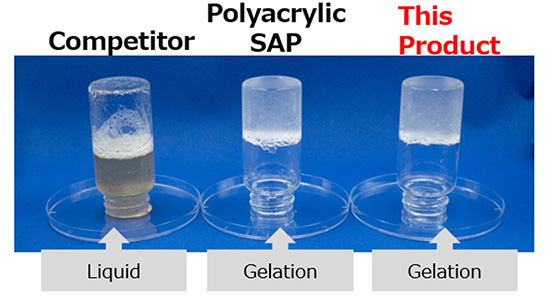

<Comparison Images>

◆Inquiries

Business Planning and Management Office, Colors & Advanced Processing Dept., NAGASE & CO., LTD.

Bio-sap@nagase.co.jp https://www.nagase.co.jp/english/

Sales: Public Relations & Branding Office, Corporate Sustainability Dept., NAGASE & CO., LTD.

Tel: +81-3-3665-3640 https://www.nagase.co.jp/english/

Development/Manufacturing: Corporate Planning Office, Corporate Planning Dept., Nagase ChemteX Corporation

https://www.nagasechemtex.co.jp/en/inquiry/form_company.html

Development: Corporate Design Dept., Hayashibara Co., Ltd.

Tel: +81-86-224-4315 https://www.nagase.com/viita/en/