Epoxy Reactive Diluent Explained: Market Trends, Benefits, & Uses

What is epoxy reactive diluents?

Reactive diluents are commonly used to adjust high-viscosity resins to low viscosity. A well-known diluent is “thinner,” and its purpose is to improve workability. Epoxy reactive diluents incorporate the epoxy group of the diluent into the molecule through a chemical reaction during curing, making it possible to adjust viscosity while suppressing a decline in performance.

Diluents can be divided into two categories: reactive diluents and no-reactive diluents. No-reactive diluents are diluents that are not incorporated into the resin network during curing, lowering the viscosity, and have the same role as plasticizers.

Market growth forecast

The global reactive diluent market was valued at approximately USD 952.04 million in 2020 and is expected to grow by over 6.6% during the forecast period 2021–2027.

In particular, investments in the construction and industrial fields are increasing in the Asia-Pacific region, and infrastructure facilities are expected to increase due to population growth, so the region is considered an important one that will gain market share among the target regions.

Based on this, it is predicted that the period from 2020 to 2027 will show the highest growth compared to other overseas regions.

Effects on epoxy resin

What kind of changes or effects can be seen on epoxy resins by using epoxy reactive diluents? Positive changes and influences make them easier to handle and more widely used.

1. Decrease viscosity

Epoxy resins are typically highly viscous materials. Therefore, there are times when they feel difficult to handle. For example, when using paints and coatings, the use of diluents improves workability and increases efficiency.

They are characterized by the fact that the number of functional groups present in the diluent molecule increases from mono to di to tri, increasing the viscosity of the diluent itself and weakening its ability to reduce viscosity.

2. Improve mechanical properties

It has been shown that the mechanical properties of epoxy resins can be improved by using diluents.Reactive diluents are incorporated into the structure of the epoxy resin as it cures, helping to create a uniform crosslinking structure, thereby increasing strength and tensile properties.

On the other hand, epoxy reactive diluents with more functional groups will reduce the density of the crosslinked structure, reducing strength and modulus, but providing additional flexibility.

3. Improve thermal stability

Resin is inherently unstable to heat and light, so exposure to heat and sunlight can cause oxidation and deterioration. In this deterioration reaction, hydrogen and chlorine in the resin structure are eliminated by heat and light, generating hydrogen chloride and causing a chain reaction of decomposition.

Epoxy reactive diluents are expected to improve thermal stability by capturing generated hydrogen chloride and preventing decomposition and deterioration.

4. Reduce VOC emissions

VOC is an abbreviation for volatile organic compounds, which refers to organic solvents that evaporate. Inhaling VOCs above a certain level into the body can affect the respiratory system and cause various diseases. Therefore, it is important to set regulations for VOC emissions.

By replacing the solvent used to mix the pigment and resin with a reactive diluent, VOC emissions can be reduced as the solvent is fully incorporated into the curing system without being removed during curing.

Example uses

Here are some examples where epoxy reactive diluents are used:

1. Coatings

Epoxy reactive diluents are also added to coating agents intended for architecture, construction, and the protection and preservation of cultural properties. They are resistant to the elements, especially outdoors where they are constantly exposed to light, heat, and rain.

2. Adhesives

They are also added to many types of adhesives, including metal, glass, wood, and concrete. When using adhesives, an important factor that determines adhesion is the influence of the hydrophilicity and hydrophobicity of the resin surface. In addition to acting as a diluent, they may also act as a resin improver.

3.Paint

As previously mentioned, epoxy reactive diluents are used to facilitate the mixing of pigments and resins. In the case of solvents, two coats may be necessary, as the film becomes thinner as the VOC evaporates and evaporates. On the other hand, epoxy reactive diluents do not generate VOCs and do not change the film thickness, so there is no need to reapply.

A versatile epoxy reactive diluent: DENACOL

What is DENACOL as epoxy reactive diluents?

DENACOL, which is used as epoxy reactive diluents, is introduced below. You can check the lineup of each product on our website. Below, we will introduce some of our representative products.

Mono-functional type

Representative monofunctional epoxy reactive diluents include "EX-121," "EX-141," and "EX-146." We will introduce the features of each.

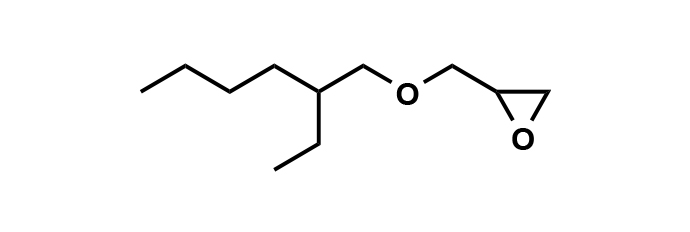

EX-121

This product is an aliphatic monofunctional epoxy compound called 2-ethylhexylglycidyl ether. Its features include monofunctionality, hydrophobicity, low viscosity, and low chlorine content, so it can be used not only as a reactive diluent but also as a resin stabilizer.

SWIPE

| Epoxy equivalent (g/eq.) |

Viscosity (mPa・s) |

Total chlorine content(%) |

Color value (APHA) |

Water solubility(%) | Packaging |

|---|---|---|---|---|---|

| 187 | 4 | 0.01 | 10 | Insoluble | 16kg、180kg |

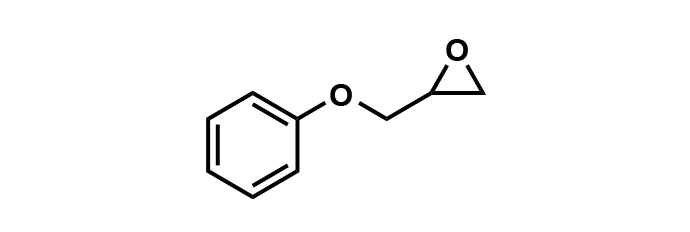

EX-141

This product is an aromatic monofunctional epoxy compound called phenyl glycidyl ether. Its features include monofunctionality, hydrophobicity, low viscosity, and low chlorine content, allowing it to be used not only as a reactive diluent but also as a resin stabilizer.

SWIPE

| Epoxy equivalent (g/eq.) |

Viscosity (mPa・s) |

Total chlorine content(%) |

Color value (APHA) |

Water solubility(%) | Packaging |

|---|---|---|---|---|---|

| 151 | 8 | 0.02 | 10 | Insoluble | 18kg、200kg |

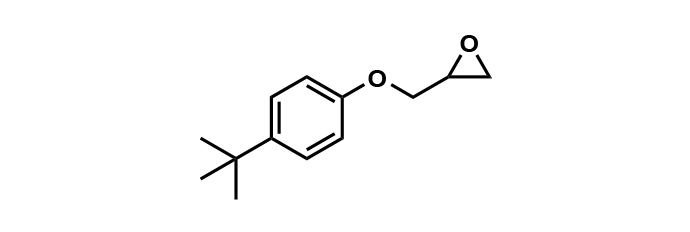

EX-146

This product is an aromatic monofunctional epoxy compound called p-tert-butylphenyl glycidyl ether. Its features include monofunctionality, hydrophobicity, low viscosity, and low chlorine content, allowing it to be used as a reactive diluent.

SWIPE

| Epoxy equivalent (g/eq.) |

Viscosity (mPa・s) |

Total chlorine content(%) |

Color value (APHA) |

Water solubility(%) | Packaging |

|---|---|---|---|---|---|

| 225 | 20 | 0.3 | <1 | Insoluble | 18kg、200kg |

Di-functional type

Representative di-functional epoxy reactive diluents include "EX-211" and "EX-810." We will introduce the characteristics of each.

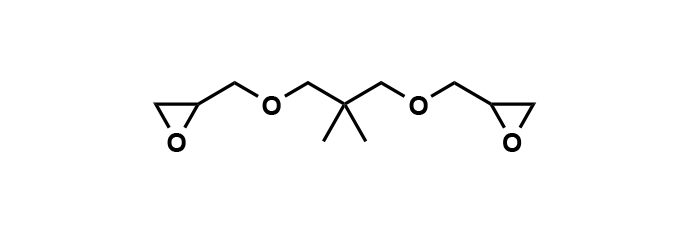

EX-211

This product is an aliphatic difunctional epoxy compound called neopentyl glycol diglycidyl ether. Its features include bifunctionality, hydrophobicity, and low viscosity, allowing it to be used as a reactive diluent.

SWIPE

| Epoxy equivalent (g/eq.) |

Viscosity (mPa・s) |

Total chlorine content(%) |

Color value (APHA) |

Water solubility(%) | Packaging |

|---|---|---|---|---|---|

| 138 | 20 | 5.7 | 10 | Insoluble | 18kg、200kg |

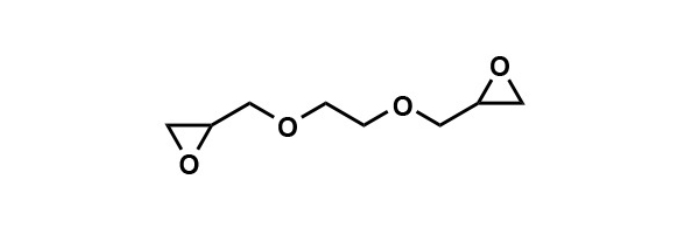

EX-810

This product is an aliphatic difunctional epoxy compound called ethylene glycol diglycidyl ether. Its features include bifunctionality, water solubility, low viscosity, and low chlorine content, allowing it to be used as a crosslinking agent for water-based resins, a hydrophilic agent, a flexibility agent, and a reactive diluent.

SWIPE

| Epoxy equivalent (g/eq.) |

Viscosity (mPa・s) |

Total chlorine content(%) |

Color value (APHA) |

Water solubility(%) | Packaging |

|---|---|---|---|---|---|

| 113 | 20 | 0.6 | 20 | 100 | 20kg、220kg |

Multi-functional type

Representative products of multifunctional epoxy reactive diluents include "EX-313," "EX-321," and "EX-321L." We will introduce the characteristics of each.

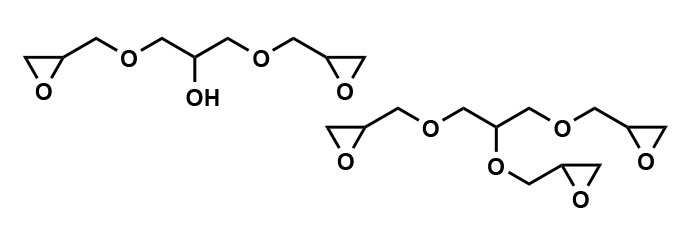

EX-313

This product is an aliphatic polyfunctional epoxy compound called glycerol polyglycidyl ether. Its characteristics include multifunctionality, water solubility, low viscosity, and high reactivity, making it suitable for use in water-based paints, crosslinking agents for adhesives, surface treatment agents for fibers, and reactive diluents.

SWIPE

| Epoxy equivalent (g/eq.) |

Viscosity (mPa・s) |

Total chlorine content(%) |

Color value (APHA) |

Water solubility(%) | Packaging |

|---|---|---|---|---|---|

| 141 | 150 | 9 | 10 | 99 | 20kg、220kg |

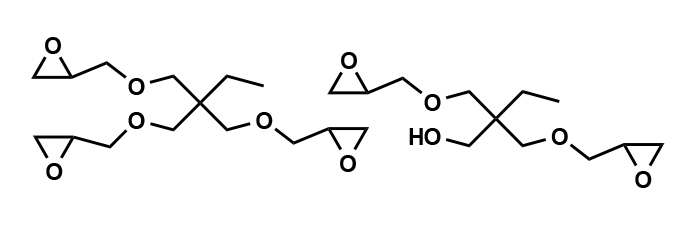

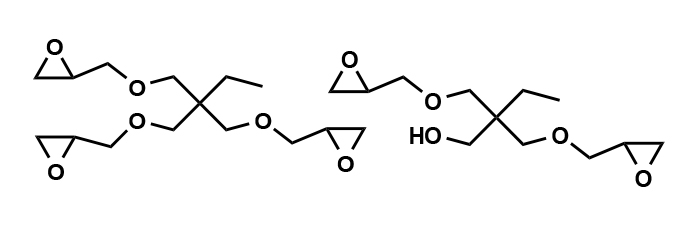

EX-321

This product is an aliphatic polyfunctional epoxy compound called trimethylolpropane polyglycidyl ether. Its features include multifunctionality, low viscosity, and high reactivity, making it useful as a crosslinking agent and reactive diluent for paints and adhesives.

SWIPE

| Epoxy equivalent (g/eq.) |

Viscosity (mPa・s) |

Total chlorine content(%) |

Color value (APHA) |

Water solubility(%) | Packaging |

|---|---|---|---|---|---|

| 140 | 130 | 7.5 | 10 | 27 | 20kg、200kg |

EX-321L

This product is an aliphatic polyfunctional epoxy compound called trimethylolpropane polyglycidyl ether. Its features include multifunctionality, hydrophobicity, low viscosity, low chlorine, and high reactivity, making it suitable for use as a reactive diluent for electronic materials.

SWIPE

| Epoxy equivalent (g/eq.) |

Viscosity (mPa・s) |

Total chlorine content(%) |

Color value (APHA) |

Water solubility(%) | Packaging |

|---|---|---|---|---|---|

| 130 | 300 | 0.3 | 30 | Insoluble | 18kg |

Get in touch!

For inquiries or to request a sample of DENACOL, our epoxy reactive diluent, please reach out to our team. We're ready to assist you with personalized service and expertise.