Polymer/Resin Stabilizers | Enhance Durability with Halogen Catchers

What is a Polymer/Resin Stabilizer?

Plastics are inherently unstable against heat and light. Due to factors such as molding processes or exposure to sunlight, they can oxidize or deteriorate. Polymer/resin stabilizers are additives used to suppress this oxidation and degradation, enhancing the durability of the resin. Many types of resins, including polyvinyl chloride (PVC) resin, are incorporated with these stabilizers.

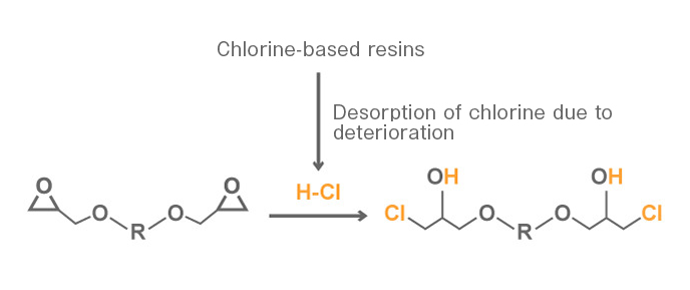

In the case of chlorinated resins like PVC, exposure to heat and light can cause the detachment of hydrogen and chlorine, leading to the release of hydrochloric acid (HCl) and triggering a chain reaction of decomposition. Resin stabilizers can capture the released HCl, thereby inhibiting this decomposition. Compounds that capture substances like HCl are commonly referred to as "halogen catchers."

Why is it Important?

To prevent oxidation and deterioration of resins, it's crucial to eliminate the factors causing them. This requires a thorough understanding of the causes of degradation and the properties of resin stabilizers. Plastic products are used in various applications and environments, and to ensure they meet the desired functionalities and characteristics, selecting the appropriate resin stabilizer is of utmost importance.

Types of Polymer/Resin Stabilizer

There are various types of resin stabilizers. Let's introduce some of the representative ones:

Halogen Catchers (Acid Scavengers)

Halogen catchers, also known as acid scavengers, are additives that effectively capture acids contained in resins, enabling the production of stable resins. They are compounds used to neutralize and capture acidic substances, especially HCl, which are produced from the thermal or photolytic decomposition of halogenated compounds (especially those containing a high amount of chlorine).

Thermal and Humidity Stabilizers

Thermal stabilizers are used to prevent degradation caused by heat. Humidity stabilizers are additives used to maintain and enhance the performance and lifespan of resins or polymer materials under high humidity or moisture conditions. By inhibiting the permeation or absorption of moisture, humidity stabilizers are used to minimize the physical and chemical deterioration of resins or materials.

Ultraviolet (UV) Stabilizers

UV stabilizers are additives used to protect resins from UV degradation. They come in various types, such as benzophenone compounds, benzotriazole compounds, and benzoate compounds. However, some have been pointed out for their environmental harm, and certain types are regulated by laws.

Antioxidants

Antioxidants are additives used to prevent oxidation or degradation caused by atmospheric oxygen. Oxidation can lead to a decrease in the strength of resins, cracking, and discoloration. To prevent these effects, antioxidants are used. Common types include phenolic, phosphate ester, and sulfur-based compounds.

Light Stabilizers

Light stabilizers are additives used to prevent oxidative degradation caused by light. When resins are exposed to sunlight or other light sources, photo-induced reactions can occur, leading to a reduction in properties and discoloration. The addition of light stabilizers can suppress these photo-induced reactions.

Applications of Polymer/Resin Stabilizers

Stabilization of PVC Resin

Stabilizers used for PVC resin include metals, such as calcium, zinc, tin, and lead. However, due to concerns about the toxicity of lead, its use has been decreasing. Consequently, there's a growing demand for calcium-zinc-based stabilizers. Epoxy plasticizers are sometimes added to enhance the function of stabilizers. While epoxy plasticizers serve as plasticizers, they are effective in improving heat and light resistance. They are essential for barium-zinc-based and calcium-zinc-based stabilizers. PVC resin, when processed, can release HCl. To prevent this, stabilizers are added.

Stabilization of PBT Resin

Polybutylene Terephthalate (PBT) is a type of polyester engineering plastic. Due to its high crystallinity, it has a semi-transparent appearance and is superior in mechanical, chemical, and electrical properties. However, because it has an ester group in its molecular structure, it is prone to hydrolysis. Therefore, polyolefin-based modifiers are usually added to PBT to enhance its hydrolysis resistance and thermal shock resistance. PBT is used for various purposes, such as electrical parts and automobile parts, and is especially widely used in automotive electrical components.

Mechanism of Action of Halogen Catchers (Acid Scavengers)

The mechanism of action of halogen catchers progresses as follows:

- 1.Starting the decomposition process

- 2.Activating the acid protection

- 3.Evening out the acid levels

- 4.Ensuring polymer stability

- 5.Distributing the salt evenly

- 6.Maintaining continuous protection

In the case of chlorinated resins like PVC, decomposition of the resin occurs first due to heat or light, producing HCl. Without stabilizers, the molecular structure becomes unstable, and the release of HCl accelerates, causing a chain reaction of decomposition. However, with the presence of halogen catchers, the released HCl is neutralized, suppressing the decomposition reaction. As a result of the action of these halogen catchers, the resin can be continuously stabilized.

Points To Consider When Choosing Resin Stabilizers

By selecting the appropriate resin stabilizer, you can achieve the desired functions and characteristics of the resin. Here are some points to consider when selecting resin stabilizers:

Compatibility With the Polymer

It's essential to choose a resin stabilizer that is compatible with the resin (base polymer) whose function or properties you wish to enhance. Resin stabilizers vary in properties, such as hydrophobicity, hydrophilicity, and viscosity. It's crucial to understand their chemical structure and physical properties. Interactions between additives are also an important consideration.

Desired Functions and Properties

The primary purpose of using a resin stabilizer is to improve the stability of the base resin against various destabilizing factors, such as heat, light (UV rays), and humidity. Depending on the application and environment, other functions and properties might also be required. It's essential to ensure that adding a resin stabilizer doesn't compromise these functions. For instance, considerations such as the desired molecular weight, acceptable chlorine content, and whether the stabilizer is aliphatic or aromatic are critical when selecting a resin stabilizer.

DENACOL | Extending the Life of Chlorinated Resins

Nagase ChemteX offers a wide range of epoxy compounds under the name "DENACOL." As resin stabilizers, these products can be used as halogen catchers and for improving hydrolysis resistance.

Below, we introduce the features and physical properties of some of our representative products. Please use them according to your application and purpose.

Halogen Catcher (Acid Scavenger)

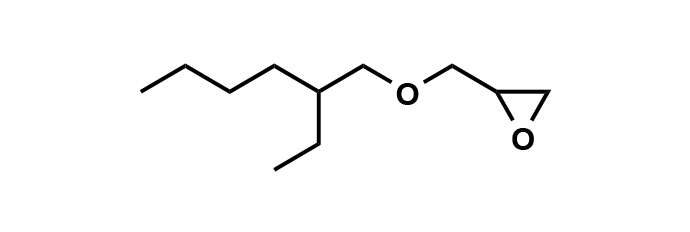

DENACOL EX-121

This product is a monofunctional epoxy compound called 2-ethylhexyl glycidyl ether. It is characterized by its hydrophobicity, low viscosity, and low chlorine content. In addition to being a resin stabilizer, it can also be used as a reactive diluent.

SWIPE

| Epoxy equivalent(g/eq.) | Viscosity (mPa・s) |

Total chlorine content(%) | Color Value (APHA) | Water solubility(%) | Packaging |

|---|---|---|---|---|---|

| 187 | 4 | 0.01 | 10 | Insoluble | 16kg, 180kg |

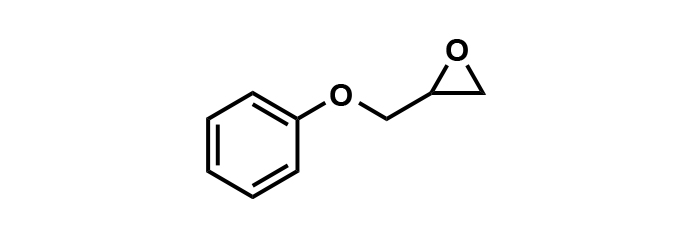

DENACOL EX-141

This product is a monofunctional epoxy compound called phenyl glycidyl ether. Its features include hydrophobicity, low viscosity,

and low chlorine content. It can be used as a resin stabilizer as well as a reactive diluent.

SWIPE

| Epoxy equivalent(g/eq.) | Viscosity (mPa・s) |

Total chlorine content(%) | Color Value (APHA) | Water solubility(%) | Packaging |

|---|---|---|---|---|---|

| 151 | 8 | 0.02 | 10 | Insoluble | 18kg, 180kg |

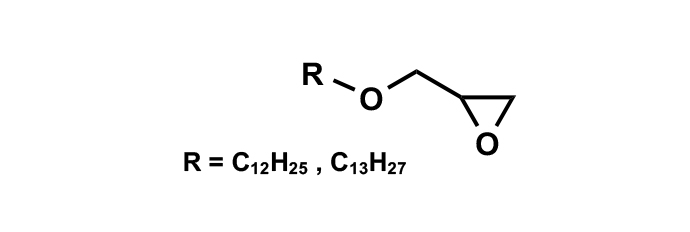

DENACOL EX-192

This product is a monofunctional epoxy compound called C12,C13 mixed-alcohol glycidyl ether. Its features include hydrophobicity and low viscosity. It can be used as a resin stabilizer as well as a reactive diluent.

SWIPE

| Epoxy equivalent(g/eq.) | Viscosity (mPa・s) |

Total chlorine content(%) | Color Value (APHA) | Water solubility(%) | Packaging |

|---|---|---|---|---|---|

| 281 | 8 | 4 | 10 | Insoluble | 15kg,170kg |

Hydrolysis Resistance

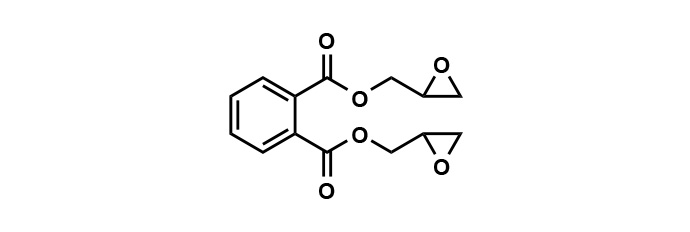

DENACOL EX-721

This product is a difunctional epoxy compound called phthalic acid diglycidyl ester. Its features include hydrophobicity, heat resistance, and high reactivity. It can be used as a resin stabilizer as well as structural material. Moreover, improved hydrolysis resistance can be expected. When 1% of this product was added to PBT resin and subjected to a hydrolysis promotion test using a pressure cooker (120°C, 100% RH), no significant changes were observed in tensile strength or elongation at break.

SWIPE

| Epoxy equivalent(g/eq.) | Viscosity (mPa・s) |

Total chlorine content(%) | Color Value (APHA) | Water solubility(%) | Packaging |

|---|---|---|---|---|---|

| 154 | 980 | 0.9 | 2 | Insoluble | 20kg |