Polymer/Resin Modifier | Boosting Epoxy Performance with DENACOL

1. What are Polymer/Resin Modifiers?

Polymer/resin modifiers are substances added to improve the functions and properties of resins. For example, they confer hydrophilic or hydrophobic properties on the resin, prevent deterioration or oxidation, and improve mechanical properties. Over the years, many polymer/resin modifiers have been developed, and when dealing with resins, it is important to understand the types of resin modifiers and choose the appropriate one.

Note: In this article, the term "polymer/resin modifier" will be referred to as "resin modifier" for the sake of simplicity.

Why is it important?

Resins are used for various purposes, and the required functions and properties differ depending on the purpose. When it is difficult to satisfy the required functions with a resin alone, the use of polymer/resin modifiers is indispensable. By using resin modifiers, new functions can be added to a resin or its properties can be improved effectively and economically with small amounts of modifiers.

2. Types of Resin Modifiers

Resin modifiers come in various types. A few representative ones are described below:

2.1 Impact Modifiers

Impact modifiers are additives used to improve the impact strength of resins. Impact strength is a mechanical property that refers to the ability to withstand shock; some resins can easily crack while others are difficult to scratch. Generally, rubber components are added and dispersed in the resin to improve its impact strength. Dispersion of inorganic particles like calcium carbonate can also enhance impact strength.

The methods to measure the impact strength of resins include pendulum-based tests like Charpy and Izod tests and falling-ball (falling-hammer)-based tests.

2.2 Resin Stabilizers

Resin stabilizers are additives used to improve the stability of resins. Resins inherently lack sufficient stability against heat and light, and they can easily oxidize or deteriorate due to heat and ultraviolet rays during molding or use. By using resin stabilizers, oxidation and deterioration can be suppressed, thus extending their lifespan. For example, in the case of PVC resins, chlorine and hydrogen can dissociate to form hydrochloric acid, thus advancing decomposition.

By using stabilizers such as calcium and zinc, decomposition can be suppressed. Also, epoxy compounds can be used with water-based resins like vinyl chloride emulsions.

2.3 Hydrophilic/Hydrophobic Modifiers

These modifiers are used to impart hydrophilic or hydrophobic functions to the resin surface. Materials that have the ability to blend with water are known as hydrophilic materials, and those that do not blend with are called hydrophobic materials. Depending on the resin used and its purpose, the hydrophilicity and hydrophobicity of the material must be considered.

For example, when using adhesives or paints, the hydrophilic or hydrophobic nature of the resin surface greatly affects adhesion, making these functions essential elements.

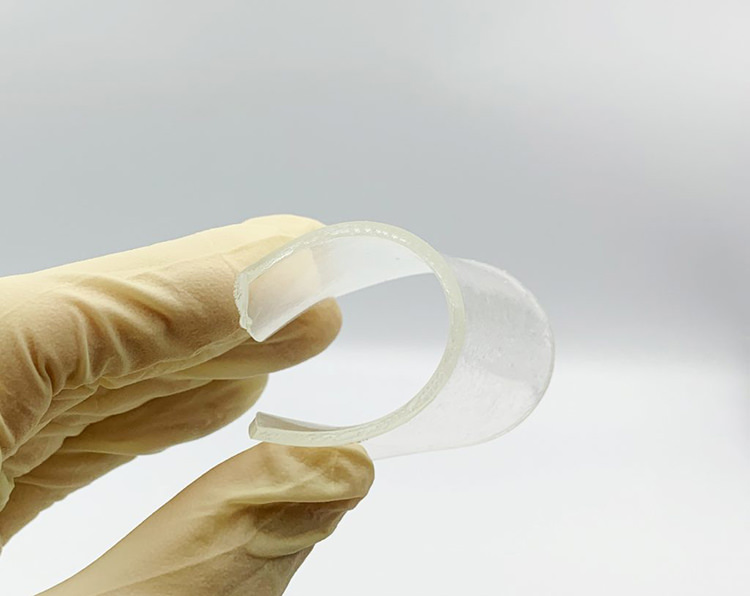

2.4 Flexibilizers/Plasticizers (Flexibility Enhancers)

Flexibilizers are additives added to resins when flexibility is required. Representative substances include phthalic acid-based and epoxy-based substances, known as plasticizers. By adding flexibilizers, the bond strength between polymers weakens, thus making the resin flexible.

3. Applications of Resin Modifiers

Resin modifiers are used in various applications. Below are some representative examples:

3.1 Automotive Industry

In the automotive field, resins are used in various parts for the purpose of lightweighting. Representative resins include polypropylene, polyvinyl chloride, polyurethane, ABS resin, etc., with polypropylene being particularly widely used. The production of domestic car bumpers involves the use of resins with added rubber materials, as performance requirements include rigidity, impact resistance, and weight reduction.

Furthermore, resins with added resin modifiers are widely used in manufacturing interior materials due to the various functions required. Hence, resin modifiers play a significant role in the automotive field.

3.2 Construction Industry

In the construction field, many types of resins, with various properties such as moldability, lightweighting, stain resistance, and adhesiveness, are used extensively. For example, when used as paint, properties such as chemical resistance, heat resistance, waterproofing, and fire resistance are required. Also, when used as an adhesive, the properties of adhesion to building materials, water resistance, and workability are required.

In such cases, many resin modifiers are used to improve the properties of construction materials.

3.3 Consumer Industry

Many resins, including resin modifiers, are used in consumer goods in daily life. For example, textile treatment agents used in the production of clothing such as shirts and handkerchiefs. These agents can impart functions such as wrinkle resistance, flexibility, and water repellency to the fibers. Also, some products require the resin to have transparency. Transparency is characterized by light transmittance and is affected by the type and structure of the resin as well as the additives used.

When the crystallinity of the resin increases, the density increases and the transparency decreases, so it is necessary to choose resin modifiers that affect the size of the crystal structure.

4. Points to Consider When Choosing Resin Modifiers

Choosing the appropriate resin modifier is essential to achieve the desired functions and properties. Below are some points to consider when selecting a resin modifier:

4.1 Compatibility with Base Polymer

It is necessary to select a resin modifier that is compatible with the resin (base polymer) whose functions and properties we want to improve. Compatibility refers to the ease with which polymers mix with each other, and it varies among polymers. If they do not mix well, it becomes difficult to achieve the expected function, so it is important to confirm compatibility with the original resin beforehand.

4.2 Desired Characteristics and Performance

The purpose of using resin modifiers is to add new functions to the base resin and obtain characteristics and performance that did not exist before. Understanding the desired characteristics, performance, and properties is crucial. Generally, the characteristics of resins and resin modifiers are determined by factors such as chemical structure, type of functional group, length of the carbon chain (flexibility), and spatial structure.

4.3 Processing Conditions and Equipment

The processing conditions and equipment involved when using resin modifiers are also important. For example, the conditions vary depending on whether they are hydrophobic or hydrophilic and aliphatic or aromatic, and whether they contain hydroxyl or halogen functional groups. Furthermore, mixers are needed to blend the resin and resin modifier. By using the appropriate equipment under optimal processing conditions, we can achieve the desired functions and properties.

5. Nagase ChemteX's Resin Modifiers, DENACOL

At Nagase ChemteX, we offer a wide variety of epoxy compound products called "DENACOL." Among resin modifiers, we offer hydrophilicity enhancers, hydrophobicity enhancers, flexibility enhancers, textile treatment agents, resin stabilizers, etc. At Nagase ChemteX, for the sake of convenience, we particularly refer to hydrophilicity and hydrophobicity enhancers as resin modifiers. Below, we present the characteristics and physical properties of representative resin modifiers. Please use them according to your application and purpose.

5.1 Hydrophilic Enhancers

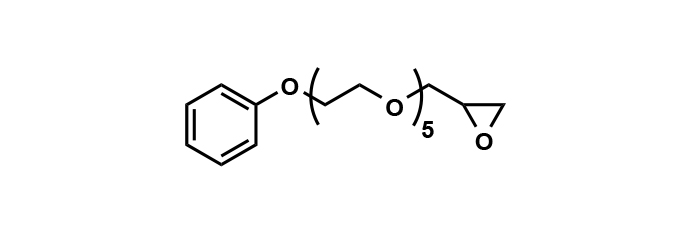

DENACOL EX-145

This product is a mono-functional epoxy compound called phenol (EO)₅ glycidyl ether. Its characteristics of water solubility, low viscosity, and low chlorine content make it suitable for use as a hydrophilic enhancer or reactive diluent. Representative physical properties include epoxy equivalent weight of 400 g/eq, viscosity of 60 mPa·s, total chlorine content of 0.3%, color value of 60 APHA, and water solubility of 100%.

SWIPE

| Epoxy equivalent(g/eq.) | Viscosity (mPa・s) |

Total chlorine content(%) | Color Value (APHA) | Water solubility(%) | Packaging |

|---|---|---|---|---|---|

| 400 | 60 | 0.3 | 60 | 100 | 20 kg , 200 kg |

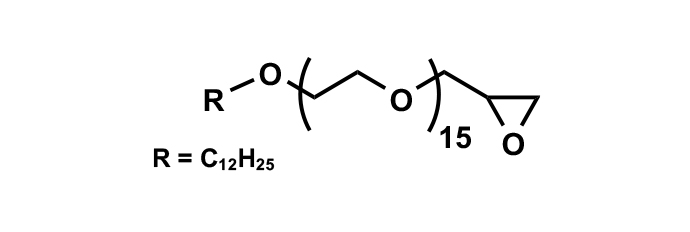

DENACOL EX-171

This product is a mono-functional epoxy compound called lauryl alcohol (EO)15 glycidyl ether. Its water solubility makes it suitable for use as a hydrophilic enhancer. Representative physical properties include epoxy equivalent weight of 971 g/eq, total chlorine content of 1.7%, color value of 10 APHA, and water solubility of 100%.

SWIPE

| Epoxy equivalent(g/eq.) | Viscosity (mPa・s) |

Total chlorine content(%) | Color Value (APHA) | Water solubility(%) | Packaging |

|---|---|---|---|---|---|

| 971 | (mp.40°C) | 1.7 | 10 | 100 | 18 kg |

5.2 Hydrophobic Enhancers

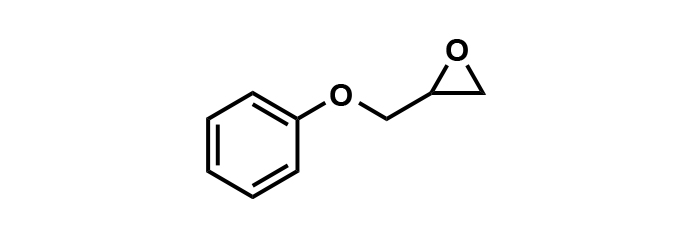

DENACOL EX-141

This product is a mono-functional epoxy compound called phenyl glycidyl ether. Characteristics include hydrophobicity, low viscosity, and low chlorine content, making it suitable for use as a hydrophobic enhancer, resin stabilizer, or reactive diluent. Representative physical properties include epoxy equivalent weight of 151 g/eq, viscosity of 8 mPa·s, total chlorine content of 0.02%, color value of 10 APHA, and water solubility of 0.

SWIPE

| Epoxy equivalent(g/eq.) | Viscosity (mPa・s) |

Total chlorine content(%) | Color Value (APHA) | Water solubility(%) | Packaging |

|---|---|---|---|---|---|

| 151 | 8 | 0.02 | 10 | Insoluble | 18 kg - 200 kg |

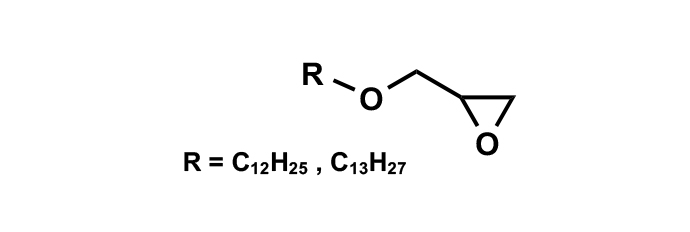

DENACOL EX-192

This product is a mono-functional epoxy compound called C12-C13 mixed alcohol glycidyl ether. Its characteristics of hydrophobicity and low viscosity make it suitable for use as a hydrophobic enhancer, resin stabilizer, or reactive diluent. Representative physical properties include epoxy equivalent weight of 281 g/eq, viscosity of 8 mPa·s, total chlorine content of 4%, color value of 10 APHA, and water solubility of 0.

SWIPE

| Epoxy equivalent(g/eq.) | Viscosity (mPa・s) |

Total chlorine content(%) | Color Value (APHA) | Water solubility(%) | Packaging |

|---|---|---|---|---|---|

| 281 | 8 | 4 | 10 | Insoluble | 15 kg - 170 kg |

Special Epoxy Compound "DENACOL"

Explore the diverse applications and innovative capabilities of DENACOL, our premier range of resin modifiers at Nagase ChemteX. Discover how we can enhance your products' performance and functionality. Learn more about DENACOL today!