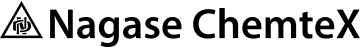

Rubber-Like Resin

Conventional resin materials have struggled to achieve both flexibility and durability. To address this challenge, we developed Rubber-Like Resin (RLR), a new material that combines rubber-like flexibility with excellent durability.

What is Rubber-Like Resin?

Toughness that won't tear even when pierced with a screwdriver

Achieves 1,000% elongation

Exceptional scratch recovery

Impact absorption comparison

You can witness its outstanding properties in actual footage, including toughness that prevents tearing even when pierced with a screwdriver, 1,000% elongation capability, natural recovery from surface scratches, and effective absorption of strong impacts.

As a groundbreaking material that achieves an unprecedented combination of toughness and flexibility—something conventional resin materials couldn't accomplish—it shows promise for applications across various industrial sectors.

Characteristics of Rubber-Like Resin

Toughness that won't tear even when pierced with a screwdriver

1,000% elongation rate and tensile strength exceeding 10MPa

Potential Applications

Coatings

Impact-absorbing covers

Scratch-resistant cover

Gaskets

Seismic protection materials

Fall protection mats

Footwear soles

Cushioning materials

Outdoor equipment

Physical Properties of Rubber-Like Resin

Property Values

Impact Absorption (Rebound Resilience)

Lower values indicate less rebound force = better shock absorption

⇒Demonstrates superior shock absorption performance compared to other vibration-damping materials

[Reference] For urethane mattresses Classification by rebound resilience:

- Less than 15%: Low resilience

- 15-49%: Regular

- 50% or higher: High resilience (high elasticity)

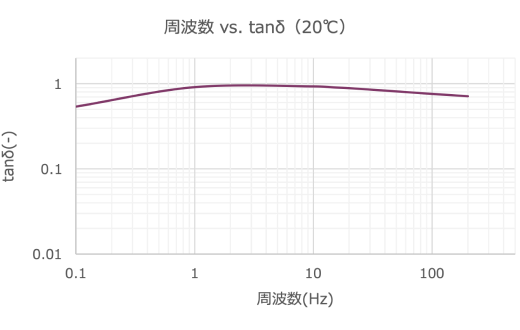

Vibration Damping (Loss factor: tanδ)

Higher values indicate better damping properties

⇒Achieves equivalent loss factor compared to other damping materials while maintaining high strength and high elongation. Also exhibits high loss factor across a wide frequency range

Weather resistance

Maintains good appearance even after 1,500 hours in Xenon Weather-Ometer (equivalent to 5 years outdoor exposure)

How to use Rubber-Like Resin

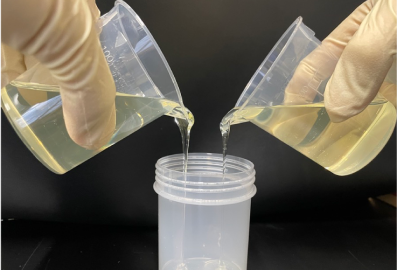

Two-component type (Resin + hardener)

Emulsion (single-component) type

Cured material shape is customizable by the customer

Rubber-Like Resin is available in both single-component and two-component formulations depending on your application needs. It can be stored at room temperature and cures at ambient temperature without requiring special equipment such as heating ovens, making it easy to handle.

Being a liquid resin, it can be molded into complex shapes. You can either pour it into molds for casting or apply it thinly as a coating. These characteristics make it suitable for various applications including component protection, reinforcement, waterproofing, and more.

Related information

High-Performance Resins & Rubbers Rankings

Tensile Strength Ranking of Elastic Resins & Rubbers

Elongation Ranking of Resins & Rubbers

Resin & Rubber + Shock Absorption (Loss Tangent (tan δ)) Ranking

Ranking of Rebound Resilience of Resins & Rubbers

Resin & Rubber Adhesion (T-peel Strength) Ranking

Resin & Rubber Weatherability (Aging Degradation) Ranking

Characteristics of silicone rubber

Characteristics of Polyurethane

Characteristics of urethane rubber