Under Layer for Bi-Layer ProcessBLX-210

Features

Reduced coating volume (good application).

Reduced defects (low solvent volatility suppresses particles during application).

Low temperature baking (no intermixing during baking below 140℃).

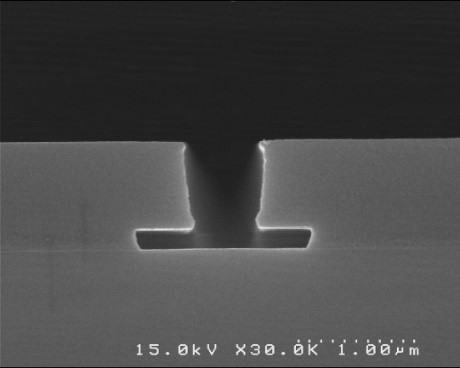

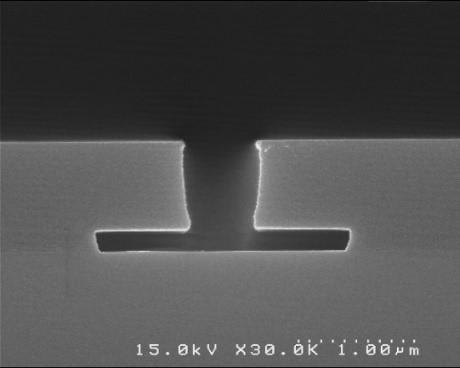

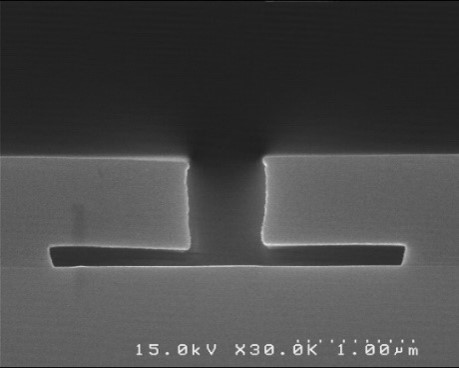

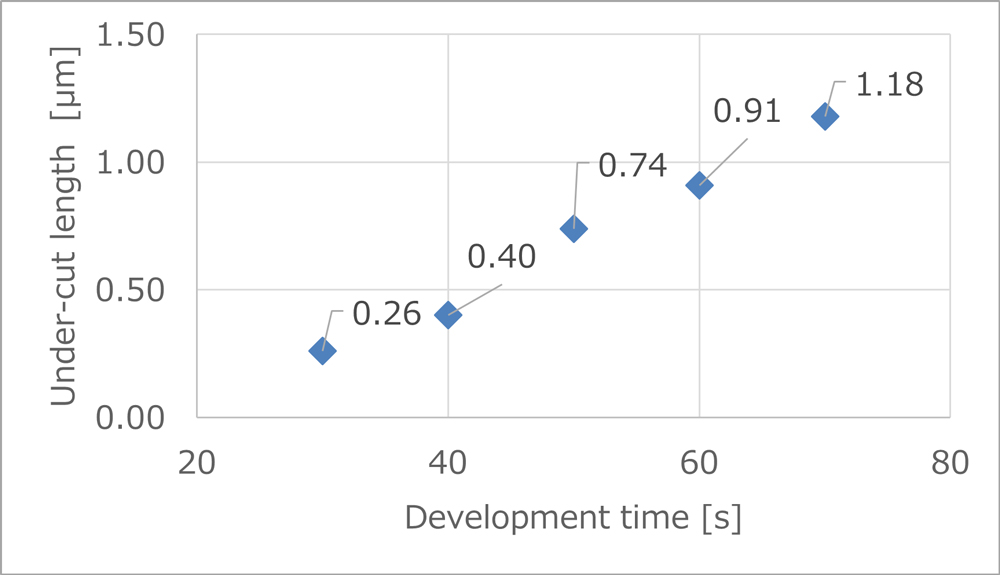

Good undercut adjustment (easy adjustment with development time).

Good peelability (low-temperature baking ensures good peelability).

Good EBR cleaning

| Process | Condition | |

|---|---|---|

| Under layer |

Substrate | 5inch Bare Si wafer |

| Coating materials | BLX-210 | |

| Coating method | Spin coating | |

| Pre-baking | 125 - 165℃, 120s on Hotplate | |

| Film thickness | 0.2 - 0.8μm | |

| Upper layer |

Coating material | Positive type of Photoresist |

| Coating method | Spin coating | |

| Prebaking | 90℃, 90s on Hotplate | |

| Film thickness | 0.8μm | |

| Double layer |

Exposure | NSR-TFHi12, (i-line stepper), NA=0.45, σ=0.6 |

| Development | 2.38%TMAH, 23℃, 30 - 70s, Single Puddle |

swipe

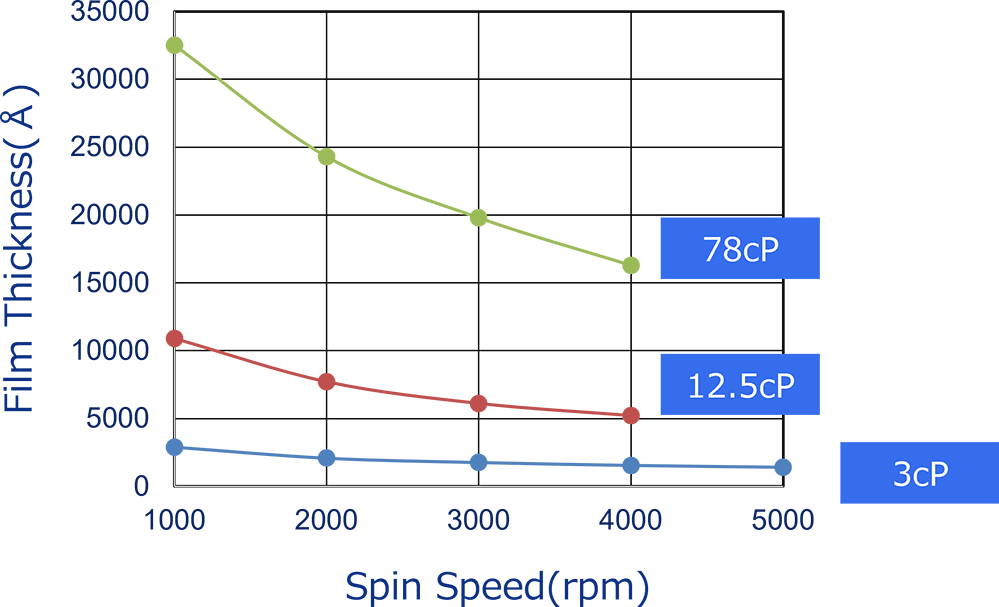

Spin curve

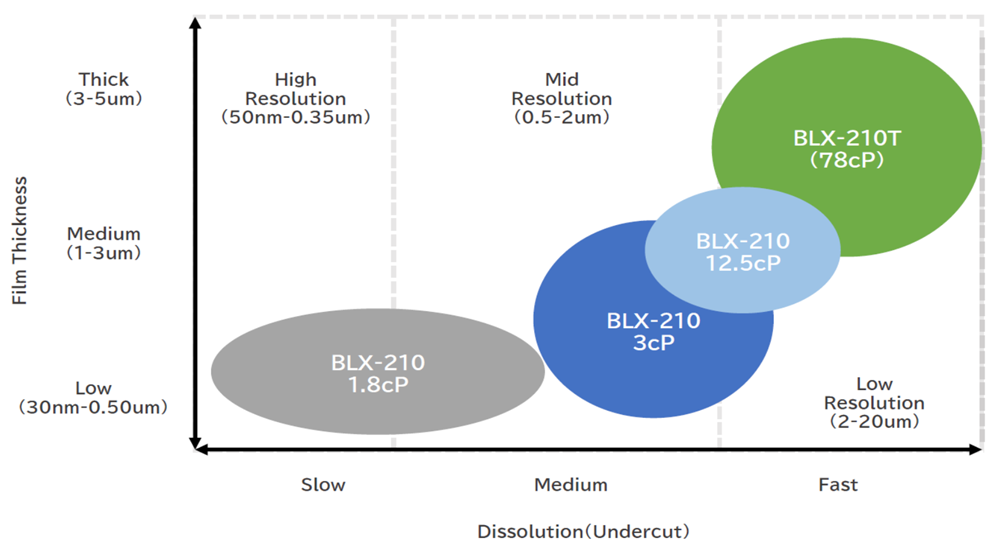

Product Range

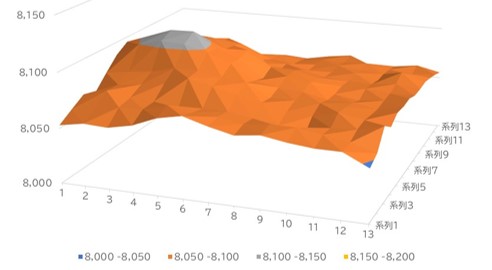

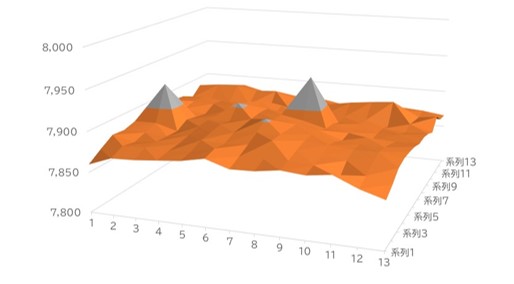

Film Thickness Uniformity

uneven coating

| Dropping volume | 2cc | 3cc |

|---|---|---|

| BLX |  |

|

swipe

in-plane film thickness uniformity

| Dropping volume | 2cc | 3cc |

|---|---|---|

| BLX |

[Average film thickness] 8,071Å

[Average film thickness] 8,071Å【σ】12.9Å |

[Average film thickness] 7,858Å

[Average film thickness] 7,858Å【σ】9.9Å |

swipe

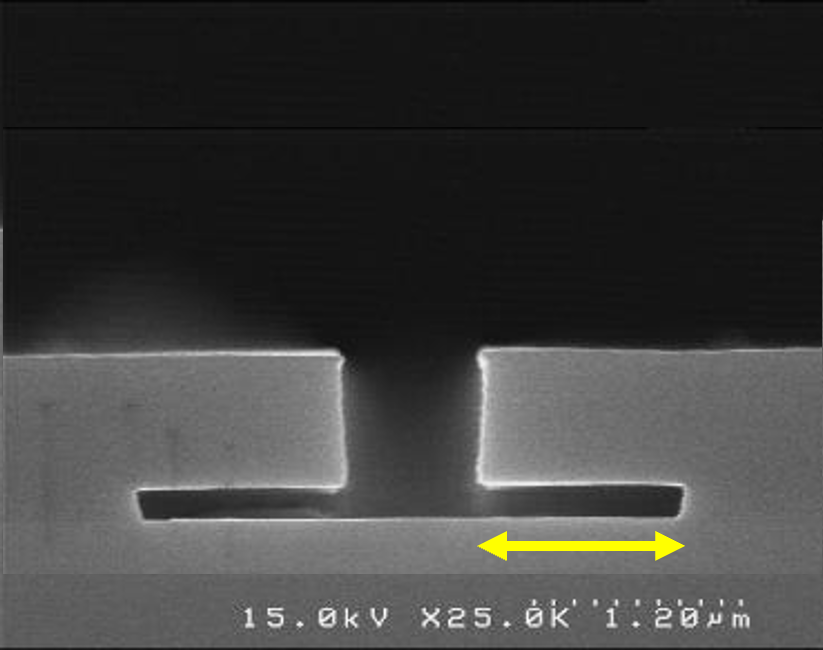

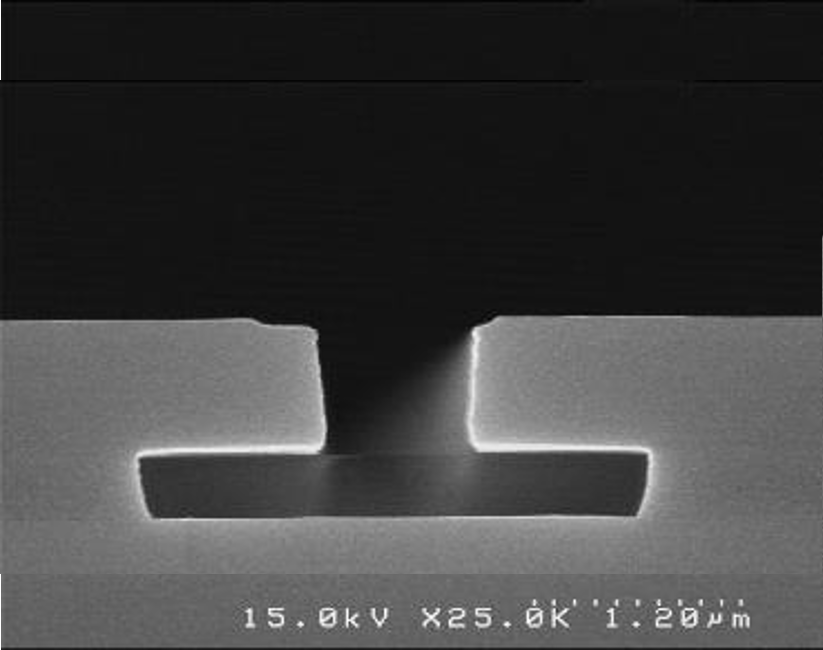

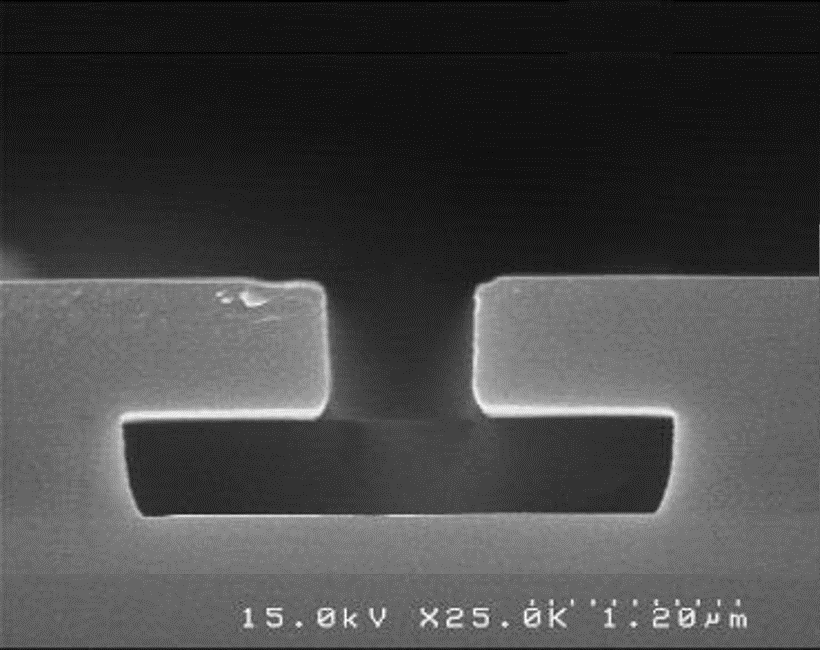

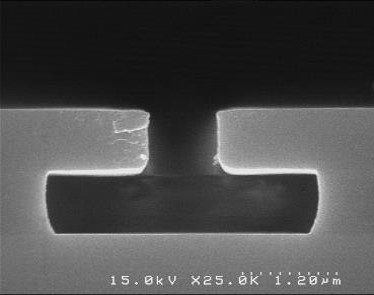

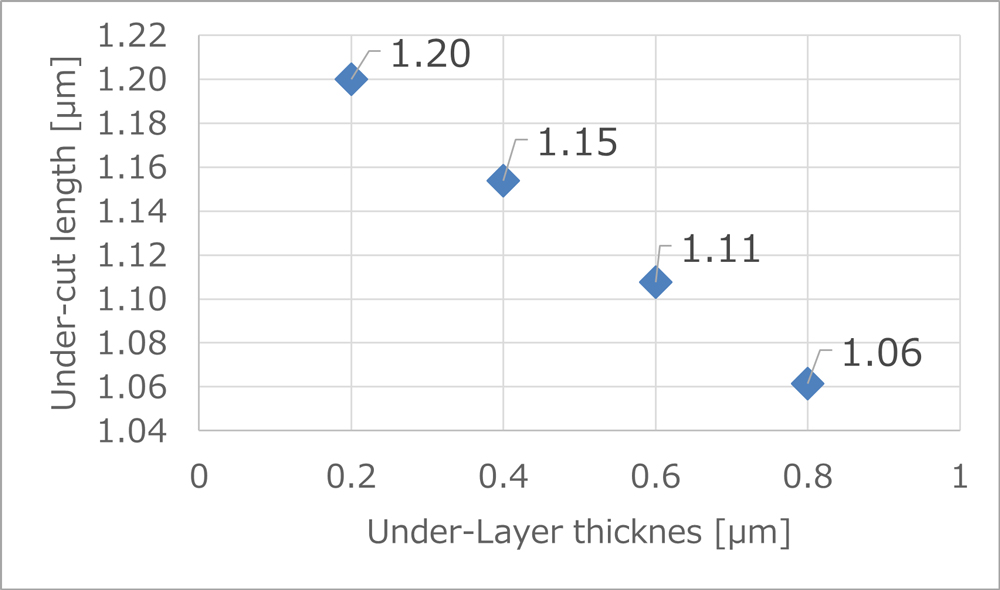

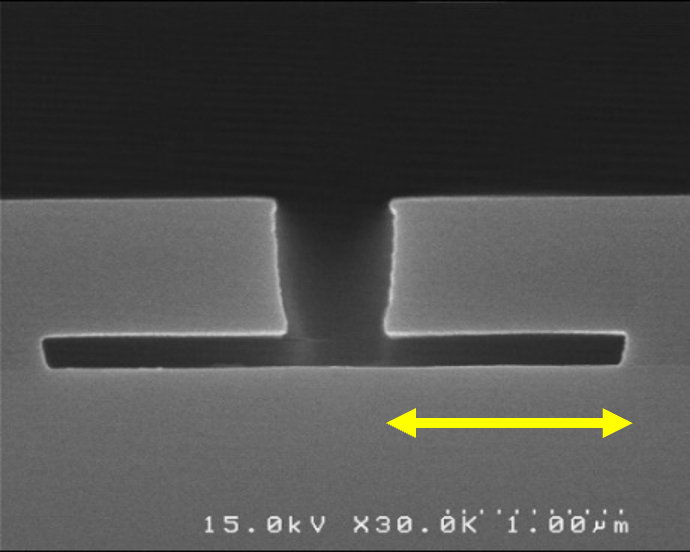

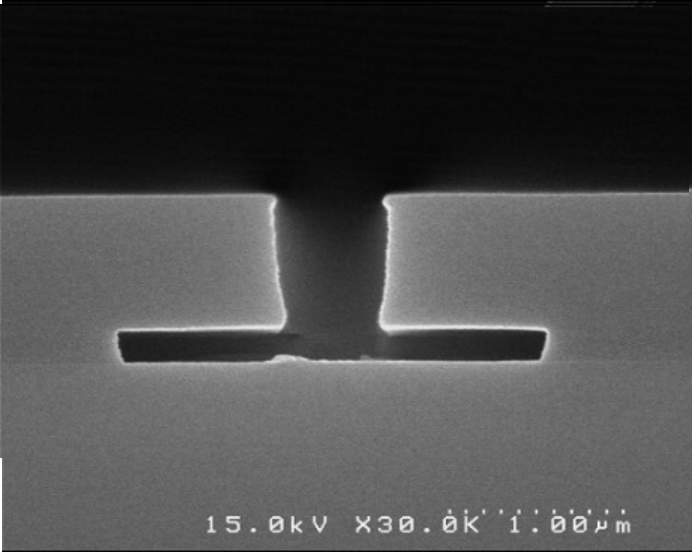

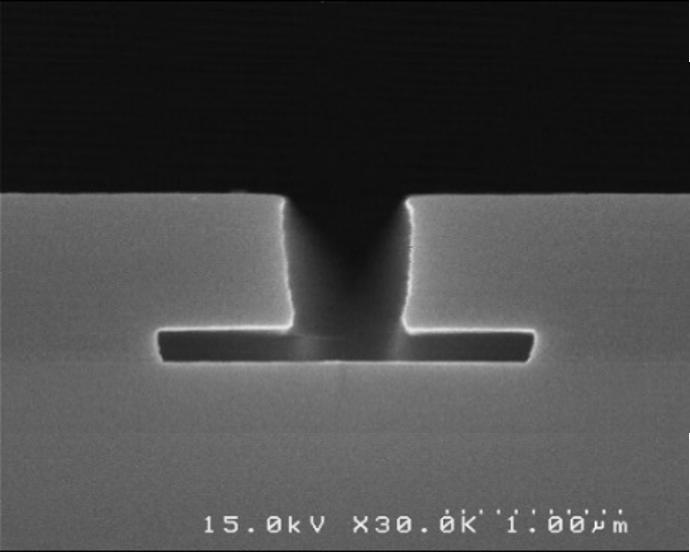

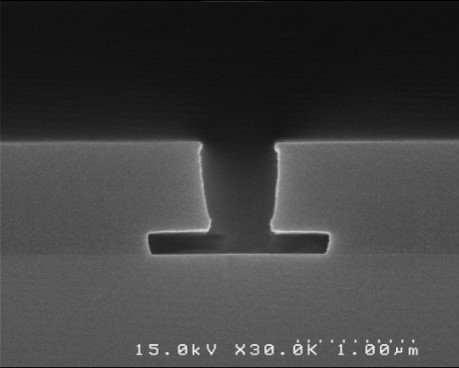

①Under-Layer thickness

-

0.2μm

-

0.4μm

-

0.6μm

-

0.8μm

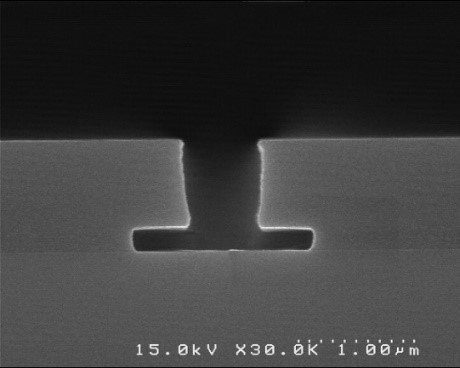

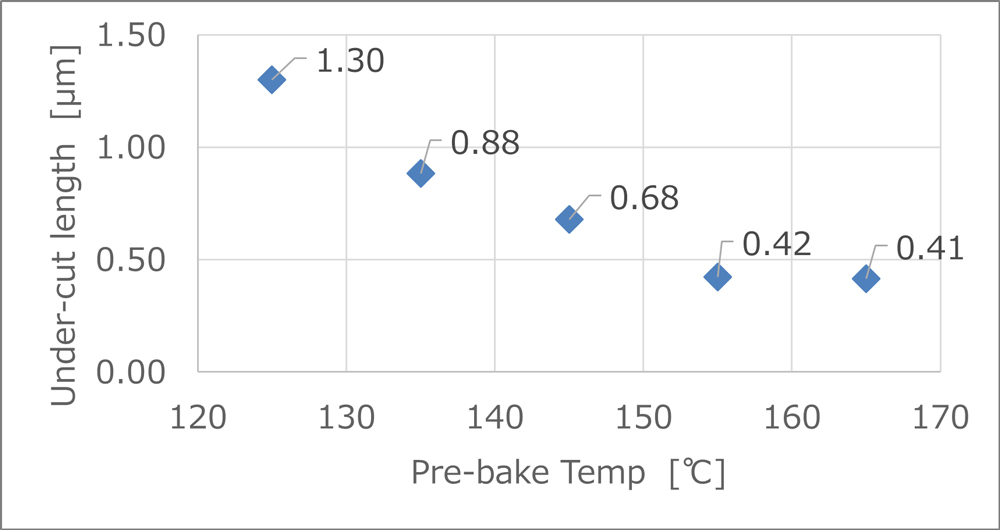

②Pre-bake Temperature

-

125℃

-

135℃

-

145℃

-

155℃

-

165℃

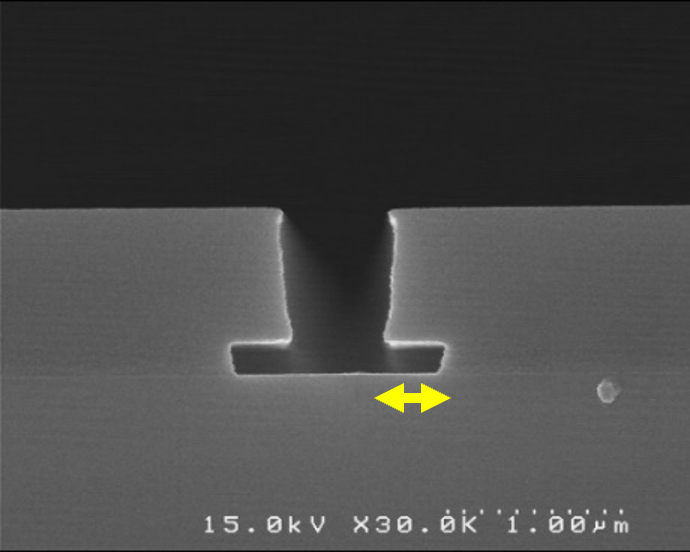

③Development time

-

30sec

-

40sec

-

50sec

-

60sec

-

70sec

Pre-bake Temp. VS Removability

| Sample | Dissolution rate for NMP (Å/s) | |

|---|---|---|

| 180℃ bake | 140℃ bake | |

| BLX | 7.6 | 27.9 |

| Other maker product | 8.0 | N/A |

swipe

Case: under-layer thickness = 2,500Å

| Sample | Complete dissolution time for NMP (s) | |

|---|---|---|

| 180℃ bake | 140℃ bake | |

| BLX | 329 | 90 |

| Other maker product | 312 | N/A |

swipe

*Competitor's products cause intermixing with the upper layer during low temperature baking , and cannot be remove or be disolved.