How to Remove Urethane Adhesives: Methods and Considerations

Urethane adhesives are widely used in automotive parts, electronics, construction materials, and sporting goods due to their ability to bond dissimilar materials such as metal, plastic, and rubber. However, because of their three-dimensional cross-linked structure and excellent chemical and abrasion resistance, removing cured adhesives without damaging the substrate is a significant challenge.

This article outlines four main approaches to the removal of urethane adhesives, discusses issues related to the use of chemical solvents, and introduces the mechanism and benefits of "easily debondable adhesives" as a promising solution.

Methods for Removing Urethane Adhesives

Removal methods for urethane adhesives generally fall into four categories: mechanical removal, thermal softening/decomposition, cryogenic embrittlement, and chemical solvents. In practice, these methods are selected individually or in combination based on the substrate material, shape, allowable adhesive residue, volume, cost, and safety.

Mechanical Removal

This involves physically grinding or scraping the adhesive using tools such as scrapers, carbon brushes, abrasive nylon brushes, sandblasting, or high-pressure water jets. Recently, systems with torque sensors mounted on robotic arms have been introduced to automatically control contact pressure and ensure uniform wear.

Advantages:

- ●General-purpose tools can be adapted at relatively low cost

- ●No liquid waste is generated, thus minimal impact from VOC regulations

- ●Allows visual inspection and fine-tuning during processing

Disadvantages / Cautions:

- ●May damage soft aluminum or thin steel sheets

- ●Requires safety measures against dust, noise, and water spray (e.g., local exhaust, enclosures, protective gear)

- ●Increases surface roughness, necessitating careful primer selection for re-bonding or repainting

Thermal Softening / Thermal Decomposition

Urethane adhesives soften at around 60-150 ℃ and thermally decompose above 200 ℃. “Thermal softening” uses tools such as hot air guns, far-infrared heaters, or induction coils for localized heating, followed by scraping. “Thermal decomposition” involves complete incineration in electric or gas furnaces.

Thermal Softening Tips:

- ●Efficient for adhesive layers up to approximately 500 µm

- ●For resin substrates, avoid deformation by keeping the heat below the glass transition temperature +10 ℃

- ●Keep surface temperature below 200 ℃ to reduce fire risk

Thermal Decomposition Tips:

- ●Suited for metal substrates or tool regeneration

- ●Use a 500–550 ℃ furnace with low oxygen to suppress isocyanate combustion

- ●Neutralize acidic exhaust gases (HCl/HCN) using alkaline scrubbers

Advantages:

- ●Effective for thick/multilayer coatings

- ●Can process materials contaminated with water or oil

Disadvantages / Cautions:

- ●Heat-sensitive resin or soldered components may be damaged

- ●Requires exhaust treatment (scrubbers/afterburners)

- ●Residual oils may ignite, posing a risk of burns/fire

Cryogenic Embrittlement

Rapid cooling with liquid nitrogen (-196 ℃) or dry ice pellets (-78 ℃) eliminates rubber-like elasticity. Impact tools such as roll crushers or cyclone grinders are then used to crush the material.

Advantages:

- ●No heat or chemicals, maintains substrate size and metal structure

- ●Crushed resin can be sieved and reused as filler

- ●Suitable for complex shapes such as cavities and porous materials

Disadvantages / Cautions:

- ●Requires vacuum-insulated tanks and nitrogen supply, high running cost

- ●May cause thermal stress cracks in welded or soldered parts

- ●Condensation after treatment may cause flash rust on ferrous materials

Chemical Solvents

Strippers for urethane adhesives typically contain components such as NMP (N-methyl-2-pyrrolidone), DMF (dimethylformamide), DMAc (dimethylacetamide), methacrylate esters, or MEA (monoethanolamine). The removal proceeds in three stages:

- Hydrolysis of ester bonds in the urethane backbone

- Softening and swelling for easier mechanical removal

- Crosslink breakdown by amine alcohols

Advantages:

- ●High removal rate even in micro gaps and capillaries

- ●Can be optimized with heat, agitation, or ultrasonic waves

- ●Dip + rinse allows for easy automation and manpower reduction

Disadvantages / Cautions:

- ●Must comply with labor safety (Organic Solvent Law), PRTR, etc.

- ●Must monitor workplace concentration (TLV-TWA/M) due to vaporization

- ●Use corrosion inhibitors (e.g., triazole) to suppress metal ion elution

Issues When Removing Urethane Adhesives with Solvents

Environmental Issues at Disposal

Used solvents may contain urethane degradation products, plasticizers, pigments, or heavy metals. Incineration as industrial waste requires careful exhaust treatment to avoid harmful emissions. If discharged, treated waste must meet legal standards. Either way, disposal costs and environmental impact are high, making solvent recycling critical.

Difficult to Remove Completely

Despite their penetration ability, chemical solvents may gel and clog deep holes, blind vias, or fine grooves (<50 µm), leading to incomplete removal. This can cause adhesion failure or blistering in re-bonding or plating processes. Additional treatment may be required:

- Ultrasonic cleaning (40 kHz, 60 ℃, 5–10 min)

- Plasma surface treatment (O₂ 30 Pa, 500 W, 120 s)

- Fluorescent penetrant inspection to detect residues (UV light in a darkroom)

Significant Damage to Substrates

Urethane strippers are often highly polar and prone to dissolving metal ions, potentially causing:

- ●Dezincification in copper/brass

- ●Surface whitening in aluminum

- ●Blackening in galvanized steel

For carbon fiber reinforced polymer (CFRP), swelling of the resin matrix may lead to interlayer delamination or reduced stiffness.

Using “Easily Debondable Adhesives” to Solve Urethane Removal Challenges

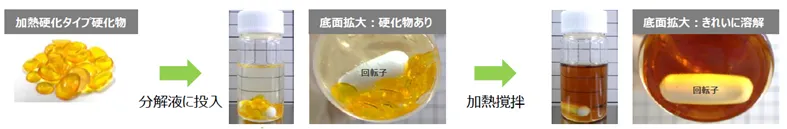

Developed by Nagase ChemteX, easily debondable adhesives deliver high bonding performance under normal conditions yet can be cleanly and safely removed under mild conditions using a special decomposition solution—with no harsh chemical solvents. They minimize substrate damage and enhance part recyclability. The decomposition liquid itself is reusable, contributing to environmental sustainability.

These adhesives incorporate reversible disulfide (S-S) bonds into the epoxy network. When immersed in the dedicated solution at ambient temperature below 60°C, these bonds are selectively cleaved, breaking down the molecular chains and dissolving the adhesive.

Key Features

Additional Benefits

- ●Safety: Easily Debondable Adhesives are halogen-free, non-toxic, and solvent-free formulation minimizes workplace risk.

- ●Multi-Material Compatibility: Enables clean separation of metal, resin, and composite interfaces.

- ●Circular Use: Reusable decomposition liquid significantly reduces disposal costs.

- ●Mass Production Ready: Jig-free batch processing (immersion → rinse → dry), suited for applications such as EV battery modules and building materials.

For more information on decomposition mechanisms, available product grades, or operational guidance, please refer to the product introduction page.