How to Remove Epoxy Adhesives (Separation and Removal Methods)

Epoxy adhesives form a three-dimensional crosslinked structure after curing, which gives them excellent heat and chemical resistance. However, this same property makes them notoriously difficult to disassemble—so much so that they are often said to be “impossible to remove once bonded.” Even after disassembly, removing residual adhesive from the substrate remains a challenge. With the growing demand for improved yield and recycling in recent years, there has been a strong need in manufacturing for technologies that can “remove adhesives quickly, cleanly, and without damaging components.”

This document outlines five major removal techniques, discusses the challenges of chemical solvent processes, and introduces the mechanism and advantages of “easily debondable adhesives” that address these challenges.

Methods for Removing Epoxy Adhesives

1. Mechanical Removal

This traditional method involves physically scraping off the resin layer using tools such as scrapers, sanders, or blasting equipment. Hand tools require minimal initial investment, and automation is possible using robotic arms with sanding heads. However, this method generates dust and often roughens the surface of the substrate.

2. Thermal Softening

Epoxy adhesives soften and become rubber-like when heated beyond their glass transition temperature (Tg). For most grades used in electronic components, this ranges from 120-200 ℃. Local heating with hot plates or heat guns followed by scraping with a spatula is a common approach.

3. Cryogenic Shock

By applying dry ice blasting or liquid nitrogen spray to rapidly cool the adhesive to temperatures of −79℃ to −196℃, cracks can be induced at the interface through thermal contraction and sublimation expansion. This method generates little dust and minimizes substrate damage, making it increasingly popular for cleaning molds and aluminum housings.

4. Chemical Solvent (High Temperature)

This approach involves immersing the adhesive in polar solvents such as dichloromethane, NMP, or DMSO, or in strong acids and bases (e.g., concentrated sulfuric acid or sodium hydroxide) at temperatures above 80°C. While fast-acting, these solvents are regulated under laws such as the Ordinance on Prevention of Organic Solvent Poisoning and the PRTR Act. Human health risks and the cost of ventilation and waste treatment systems are key bottlenecks.

5. Thermal + Pressure (Thermal Shock)

This advanced technique heats the adhesive near its Tg, then applies shear stress via pressing, followed by rapid cooling, to accumulate thermal stress and induce sudden delamination. A “heat–cool cycle” repeated dozens of times, often with dry ice cooling, can be configured for mass-production lines.

Challenges of Removing Epoxy Adhesives Using Chemical Solvents

Environmental Impact and Waste

Epoxy adhesives are difficult to recycle or incinerate, leading to high environmental impact when disposed of. The use of chemical solvents increases total waste volume and requires significant energy for re-distillation, if solvents are to be reused. These factors contribute to higher CO₂ emissions.

Difficulty of Complete Removal

Swelling the adhesive with solvents can leave behind residues known as “smears” in the micro-pores of the substrate. These residues can weaken future bonds. Even long immersion times may not fully remove the adhesive, and in the case of electronic or optical components, even a few microns of residue can be fatal defects, requiring extreme caution.

Energy Costs

Solvents such as NMP have high boiling points (e.g., 202℃), requiring substantial energy for distillation. Even when reused, the overall CO₂ reduction across the life cycle is considered limited.

Substrate Damage

For aluminum substrates, strong bases such as sodium hydroxide can cause corrosion, hydrogen embrittlement, and paint peeling. During anodized aluminum stripping, surface roughening in caustic soda baths has been known to reduce fatigue strength. Plastic substrates can also be dissolved by organic solvents, requiring careful handling.

Easily Debondable Adhesives: A Solution to Chemical Solvent Challenges

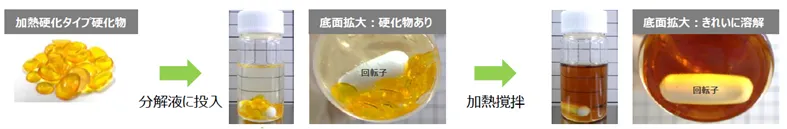

Developed by Nagase ChemteX, easily debondable adhesives deliver high bonding performance under normal conditions yet can be cleanly and safely removed under mild conditions using a special decomposition solution—with no harsh chemical solvents. They minimize substrate damage and enhance part recyclability. The decomposition liquid itself is reusable, contributing to environmental sustainability.

These adhesives incorporate reversible disulfide (S-S) bonds into the epoxy network. When immersed in the dedicated solution at ambient temperature below 60°C, these bonds are selectively cleaved, breaking down the molecular chains and dissolving the adhesive.

Key Features

Additional Benefits

- ●Safety: Easily Debondable Adhesives are halogen-free, non-toxic, and solvent-free formulation minimizes workplace risk.

- ●Multi-Material Compatibility: Enables clean separation of metal, resin, and composite interfaces.

- ●Circular Use: Reusable decomposition liquid significantly reduces disposal costs.

- ●Mass Production Ready: Jig-free batch processing (immersion → rinse → dry), suited for applications such as EV battery modules and building materials.

For more information on decomposition mechanisms, available product grades, or operational guidance, please refer to the product introduction page.