Disadvantages of Hot Melt Adhesives: Issues in Peeling and Cleaning Removal

Hot melt adhesives (hot melt glues) are widely used across various industries—from packaging, paper containers, and furniture to home appliances and semiconductor packaging—thanks to their solvent-free and instant-curing properties. However, when considering their adoption in practical applications, several concerns typically arise, such as “What is the maximum heat resistance?” “Will peeling in post-processing cause damage?” or “Will it pose problems in recycling processes?”

This article focuses on the disadvantages of hot melt adhesives, offering a systematic explanation of peeling and cleaning methods as well as environmental measures. It also introduces recent trends in “easily debondable adhesives,” which are gaining attention in rework and recycling environments.

Disadvantages of Hot Melt Adhesives

Low Heat Resistance of Adhesive

Since hot melt adhesives are primarily composed of thermoplastic resins, their bonding strength decreases when they soften or melt at high temperatures. Heat resistance varies depending on the base polymer: approx. 50-65 ℃ for EVA-based, 100-140℃ for polyamide-based, and 60-100 ℃ for polyolefin-based adhesives. Even reactive polyurethane types, known for higher heat resistance, typically range from 100-140 ℃. Exceeding these temperatures sharply reduces shear strength at joints, increasing the risk of creep failure due to stress or vibration.

For example, there have been complaints relating to automotive interior parts bonded with hot melt adhesive to black-coated panels delaminating due to high dashboard surface temperatures during summer months.

Requires High-Temperature Application

Many hot melt adhesives must be melted at temperatures approx. 80-150 ℃, leading to costs and risks associated with heating.

- ●Increased Energy Costs: Using a 500 W hot melt gun for 8 hours daily results in 4 kWh/day and 1,000 kWh/year for 250 working days. The associated electricity and CO₂ emissions are non-negligible.

- ●Resin Degradation and Line Downtime: Prolonged high-temperature storage can cause oxidation, molecular degradation, yellowing, and carbon sludge, leading to clogged nozzles and production line halts.

- ●Worker Safety Concerns: Contact with molten resin can cause severe burns. Safety measures should include shielding heat sources and providing insulation and protective equipment such as heat-resistant gloves and flame-retardant aprons.

Challenges in Recycling

While hot melt adhesives are environmentally friendly due to their solvent-free formulation, they can pose challenges in recycling. For example, in paper recycling, hot melt residues may remain as contaminants and degrade paper quality.

They can also adhere to drainage pipes and cause equipment issues. The European Packaging and Packaging Waste Directive (PPWD) emphasizes “recyclability” in product design, prompting moves to avoid hot melt adhesives.

Methods for Removing Hot Melt Adhesives (Peeling and Cleaning)

Heat Softening and Wiping

Local heating using heat guns or infrared heaters softens the adhesive for removal using wipers or scrapers. This is most suitable for substrates such as PE films or cardboard that tolerate heat. Applying a small amount of silicone oil beforehand can help prevent re-adhesion during cooling and improve wiping efficiency.

Low-Temperature Brittling (Cryobreaking)

For heat-sensitive materials such as ABS housings or lithium-ion battery laminates, rapidly cooling the adhesive below its glass transition temperature makes it brittle. The bond can then be fractured with light impact. Dry ice blasting or liquid nitrogen spray are commonly used, and subsequent processing occurs after the substrate returns to room temperature.

Solvent/Cleaner Soaking

EVA- or polyolefin-based hot melts can swell significantly in citrus-based terpene solvents or D-limonene cleaners. After soaking, air-blowing, ultrasonic cleaning, and water rinsing are used to remove the adhesive.

However, materials such as polycarbonate or PMMA may develop environmental stress cracking (ESC) with these solvents, so compatibility should be tested in advance.

Laser/IR Spot Heating

In precise applications such as semiconductor packaging, “laser debonding” using 355 nm UV lasers can decompose and remove hot melt adhesives. This minimizes heat impact on solder joints of small components. Although equipment cost is higher than hot plates, the method offers higher yields and is increasingly used in high-value product lines.

Challenges in Peeling Hot Melt Adhesives

Substrate Damage from Heat Peeling

Thin aluminum fins or flexible substrates may warp or experience yellowing due to thermal expansion differences during heating. ITO transparent electrodes are particularly vulnerable to heat cycles, potentially degrading conductivity and causing malfunctions. Limiting the heating area using specialized jigs with “corner spot” heating is essential.

Incomplete Removal

Hot melt adhesives may contain fillers such as petroleum-based wax or calcium carbonate (CaCO₃) to enhance tackiness. These can remain in fiber gaps or on surfaces even after removal, affecting subsequent processes.

Examples include contamination on painted surfaces, poor solder wetting, and cloudy optical lenses. As a countermeasure, final cleaning with electrostatic blasting (dry CO₂ snow) or plasma cleaning is increasingly adopted.

Hazards During Heat Peeling

Heating hot melt adhesives can generate harmful thermal decomposition products or fumes. To mitigate these risks, proper ventilation (e.g., local exhaust systems) and personal protective equipment (PPE) are critical.

“Easily Debondable Adhesives” Overcoming Hot Melt Peeling Issues

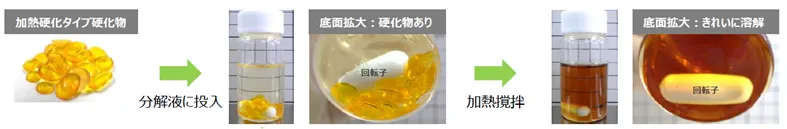

Developed by Nagase ChemteX, easily debondable adhesives deliver high bonding performance under normal conditions yet can be cleanly and safely removed under mild conditions using a special decomposition solution—with no harsh chemical solvents. They minimize substrate damage and enhance part recyclability. The decomposition liquid itself is reusable, contributing to environmental sustainability.

These adhesives incorporate reversible disulfide (S-S) bonds into the epoxy network. When immersed in the dedicated solution at ambient temperature below 60°C, these bonds are selectively cleaved, breaking down the molecular chains and dissolving the adhesive.

Key Features

Additional Benefits

- ●Safety: Easily Debondable Adhesives are halogen-free, non-toxic, and solvent-free formulation minimizes workplace risk.

- ●Multi-Material Compatibility: Enables clean separation of metal, resin, and composite interfaces.

- ●Circular Use: Reusable decomposition liquid significantly reduces disposal costs.

- ●Mass Production Ready: Jig-free batch processing (immersion → rinse → dry), suited for applications such as EV battery modules and building materials.

For more information on decomposition mechanisms, available product grades, or operational guidance, please refer to the product introduction page.