Introduction to Adhesives by Heat Resistance (100℃+, 200℃+, 300℃+)

Adhesive failure under high temperatures poses challenges across various fields—from reflow soldering in electronics, to automotive engine compartments, and sealing in fuel cell stacks.

This article classifies representative adhesives by heat-resistance zones, from approximately 100℃ to beyond 300℃, and provides key selection points, application examples, and recommended curing/post-curing conditions to maximize performance. It can serve as a useful reference when considering replacements in your process or working to reduce bonding failures.

Adhesives with Heat Resistance Between 100°℃ and 200℃

Debondable Adhesives

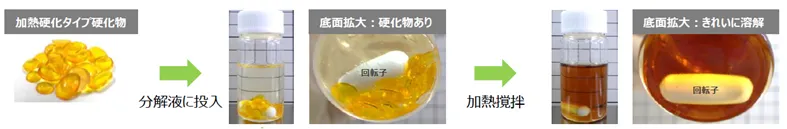

These adhesives incorporate disulfide (S-S) bonds into the epoxy backbone, achieving approx. 17 MPa shear strength and good heat resistance at ambient temperature. A key feature is that they can be disassembled after four hours at 60℃ in a special decomposition liquid. Widely adopted in electric vehicle (EV) battery and precision module rework, they support circular design initiatives by combining durability and disassemblability.

General-Purpose Epoxy

A two-part system of bisphenol-A epoxy resin with modified amine hardener. With a glass transition temperature (Tg) of 120–140℃ and shear strength of 15–25 MPa, post-curing at 80℃ for two hours increases crosslink density, enabling resistance to short-term solder reflow at 150℃. Ideal for metal/carbon fiber reinforced polymer (CFRP) structural bonding and printed circuit board component fixation.

Ambient temperature Vulcanizing (RTV) Silicone

Primarily alkoxy-based. With heat resistance up to 180℃ and shear strength of 1–4 MPa, the flexible layer reduces thermal stress during cycling, making it suitable for power semiconductor encapsulation. Moisture cure for 24 hours followed by a four-hour post-cure at 150℃ stabilizes bonding strength.

Modified Cyanoacrylate

Conventional grades had approx. 80℃ heat resistance, but partial urethane crosslinking has raised Tg, extending usability to 140℃. Enables instant bonding of glass and metals, suitable for soldering jigs and temporary optical component fixation.

Anaerobic Acrylic

Effective for bonding iron or stainless steel with ≤0.05 mm gaps. Tg approx. 130℃, heat resistance up to approx. 175℃. Known for thread locking, but now also used in the thin bonding of vulcanized rubber to metal.

Adhesives with Heat Resistance Between 200℃ and 300℃

High-Temperature Epoxy

Novolac-based epoxy cured with anhydrides achieves Tg > 200℃. Shear strength 25–35 MPa. Recommended cure: 150 for two hours followed by 200℃ for two hours. Used in power relay encapsulation for electronic control units (ECUs) and oil pan bonding in automotive applications.

Phenolic Resin

Resole-type phenolic resin cured with hexamine. Tg remains stable even at 270℃. Requires primer for metal bonding. Offers >30 MPa compression shear strength and is used in backing plate bonding for friction materials.

High-Temperature Silicone

Phenyl vinyl methyl silicone allows continuous use at 250℃. Shear strength 4–6 MPa, with excellent insulation and arc resistance. Used in LED modules and connector encapsulation. Post-cure at 180℃ for eight hours removes volatiles.

Cyanate Ester/Bismaleimide

Cyanate ester and bismaleimide resins reach Tg 200–280℃. Retain strength post-glass transition, used for CFRP honeycomb bonding in aerospace. Requires cure under ≥3 MPa pressure in autoclave at ≥180℃.

Adhesives with Heat Resistance Above 300℃

Ultra-High Temperature Epoxy

Tri-functional epoxy reacts with aromatic amines and anhydrides in multi-step curing, achieving Tg 320℃. With over-carbonized structure, shrinkage is minimal. Shear strength approx. 30 MPa. Applied in rocket engine components and fixtures in vacuum furnaces.

Polyimide-Based

Polyimide varnish undergoes imidization curing at 250–300°C. Continuous use at 350℃; peaks up to 500℃. Shear strength 20–28 MPa. Low outgassing in vacuum/radiation environments. Used in space structures and semiconductor tape automated bonding (TAB) reinforcement. Solvents are shifting from N-Methyl-2-pyrrolidone to gamma-butyrolactone/cyclopentyl methyl ether-based systems.

Ceramic/Inorganic

Water-glass (Na₂O–SiO₂) or calcium aluminate systems with microsilica are pre-dried at 120℃, sintered at 800℃. Heat resistance exceeds 1000℃. Dielectric constant <4. Unlike organic adhesives, these cure via melt infiltration and are used for corrosion-resistant pipe joints and heating element fixtures.

Reinforced Cyanate Ester

Toughened with multifunctional polyether ether ketone oligomers, achieving Tg 310℃ and shear strength 40 MPa. Withstands –55 to 260℃ thermal cycling up to 5,000 cycles without cracking. Gaining attention for silicon carbide power module encapsulation.

Easily Debondable Adhesives Combine High Heat Resistance with Clean Removability

Developed by Nagase ChemteX, easily debondable adhesives deliver high bonding performance under normal conditions yet can be cleanly and safely removed under mild conditions using a special decomposition solution—with no harsh chemical solvents. They minimize substrate damage and enhance part recyclability. The decomposition liquid itself is reusable, contributing to environmental sustainability.

These adhesives incorporate reversible disulfide (S-S) bonds into the epoxy network. When immersed in the dedicated solution at ambient temperature below 60°C, these bonds are selectively cleaved, breaking down the molecular chains and dissolving the adhesive.

Key Features

Additional Benefits

- ●Safety: Easily Debondable Adhesives are halogen-free, non-toxic, and solvent-free formulation minimizes workplace risk.

- ●Multi-Material Compatibility: Enables clean separation of metal, resin, and composite interfaces.

- ●Circular Use: Reusable decomposition liquid significantly reduces disposal costs.

- ●Mass Production Ready: Jig-free batch processing (immersion → rinse → dry), suited for applications such as EV battery modules and building materials.

For more information on decomposition mechanisms, available product grades, or operational guidance, please refer to the product introduction page.