Decomposition Liquids as Alternatives to Adhesive Solvents: Improving Workplace Safety and Solving Recycling Challenges

“We’re running out of space because of rising solvent costs and growing numbers of waste solvent drums.”

“Our workers are developing dermatitis and rhinitis—we’re beginning to suspect solvent poisoning or allergies.”

These are common concerns voiced in bonding and painting operations. While traditional solvents such as toluene and methyl ethyl ketone are highly effective cleaners, they are difficult to recycle and pose fire, explosion, and health hazards.

This article outlines the problems associated with conventional adhesive solvents and introduces decomposition liquids used in easily debondable adhesives as a safer, more

sustainable alternative. It’s a must-read for production engineers and environment, health, and safety professionals struggling with solvent disposal.

Adhesive Solvent Challenges

Recycling and Disposal Challenges

Low-viscosity organic solvents dissolve adhesives and pigments, turning them into extremely tacky and contaminated waste liquids. This makes distillation-based recycling technically and economically challenging. In fact, over 80% of solvent recovery methods in manufacturing rely on distillation, but recovery rates fall to 30–50% for waste solvents containing high resin or oil content.

Japan’s Waste Management Law requires businesses to properly dispose of industrial waste, including used solvents, and mandates manifest tracking even for outsourced disposal. As incineration produces CO₂ and incurs excessive costs, reducing consumption per unit and building solvent recycling frameworks have become unavoidable issues.

Fire and Explosion Hazards

Many cleaning solvents, such as toluene, acetone, and cyclohexane, have extremely low flash points (-20℃ to 7℃), making them easily ignitable by static sparks. When using indoor storage tanks or ultrasonic cleaners, facilities must invest in exhaust ducts, explosion-proof systems, and grounding. Because the lower explosive limit of these solvents is low, ventilation interruptions can rapidly lead to hazardous concentrations. As a result, procurement standards increasingly call for low volatile organic compound and high-flash point alternatives.

Occupational Health Risks

Toluene, a representative solvent, affects the central nervous system and is known to cause acute symptoms like headaches, dizziness, and fatigue, as well as long-term effects, such as memory loss and peripheral neuropathy.

N-Methyl-2-pyrrolidone, which is highly water-soluble and absorbed through the skin, has shown fetal toxicity in animal studies. The European Union classifies it under the Classification, Labelling and Packaging Regulation as Reproductive Toxicity Category 1B.

Furthermore, strongly alkaline paint removers (pH > 13) and acidic cleaners (pH < 2) instantly hydrolyze proteins and skin lipids, causing contact dermatitis or chemical burns. Chronic exposure can sensitize the immune system, leading to allergic reactions, such as hives or bronchial spasms, from even minute exposure. Therefore, pH neutrality and low toxicity are critical evaluation criteria for preventing solvent allergies.

Decomposition Liquids as Solvent Alternatives

The special decomposition liquids developed for use with easily debondable adhesives selectively cleave disulfide (S–S) bonds embedded in epoxy resin backbones, allowing for reversible debonding at mild conditions (Ambient temperature below 60°C).

Complete Removal Without Residue

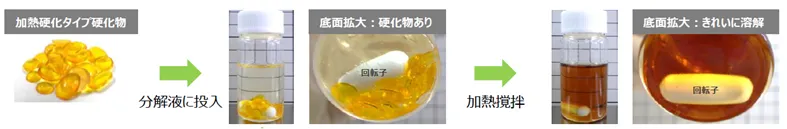

The decomposition liquid is co-designed with the resin and contains an optimized mix of reducing agents and polar solvents to break the S–S bonds. In experiments, 100 mg of a cured adhesive was completely dissolved in 24 hours at 25℃ and four hours at 60℃.

No resin flakes or whitening remained on aluminum or plastic surfaces. When combined with ultrasonic agitation, cycle times can be further shortened, making it possible to build grind-free debonding processes on production lines.

Ease of Recycling

Once removed, the resin can be thermoplastically reshaped and rebonded by reforming S–S crosslinks. The decomposition liquid itself is also recoverable, enabling a closed-loop system of adhesive → product use → debonding → adhesive reuse—simultaneously supporting solvent recycling and CO₂ reduction.

Minimal Damage to Substrates

The ET-071 series includes two grades: a single-phase type (WO-002) and a two-phase type (oil layer WO-003/water layer WW-003). Both decomposition liquids are pH-neutral, require no high-temperature processing beyond the glass transition temperature of base materials, and do not degrade metals or resins. They have been successfully evaluated for use in reworking optical lenses and power semiconductor modules.

The decomposition liquid is low-odor and formulated only with substances not subject to Japan’s Pollutant Release and Transfer Register Law, dramatically improving the working environment.

"Easily debondable adhesive" that can be removed when desired

Developed by Nagase ChemteX, easily debondable adhesives deliver high bonding performance under normal conditions yet can be cleanly and safely removed under mild conditions using a special decomposition solution—with no harsh chemical solvents. They minimize substrate damage and enhance part recyclability. The decomposition liquid itself is reusable, contributing to environmental sustainability.

These adhesives incorporate reversible disulfide (S-S) bonds into the epoxy network. When immersed in the dedicated solution at ambient temperature below 60°C, these bonds are selectively cleaved, breaking down the molecular chains and dissolving the adhesive.

Key Features

Additional Benefits

- ●Safety: Easily Debondable Adhesives are halogen-free, non-toxic, and solvent-free formulation minimizes workplace risk.

- ●Multi-Material Compatibility: Enables clean separation of metal, resin, and composite interfaces.

- ●Circular Use: Reusable decomposition liquid significantly reduces disposal costs.

- ●Mass Production Ready: Jig-free batch processing (immersion → rinse → dry), suited for applications such as EV battery modules and building materials.

For more information on decomposition mechanisms, available product grades, or operational guidance, please refer to the product introduction page.