Comparison of Tensile Shear Strength of Adhesives|Curing Methods to Maximize Bond Strength

Issues such as “Bond failure due to insufficient strength” or “Gap expansion caused by creep deformation” can be mitigated by systematically understanding the shear strength of adhesives and the optimal curing conditions that enhance bond strength.

This article compares the tensile shear strength (unit: MPa) of six major adhesive types—in accordance with JIS K 6850 / ASTM D1002—and describes methods for optimizing curing conditions. It can serve as a reference guide when testing new adhesive materials in your production line.

Shear Strength by Adhesive Type

Epoxy (Two-Part): 12–25 MPa

Typically composed of bisphenol-A resin and modified amine hardeners. Due to its high crosslink density, an epoxy is widely used in structural bonding for metals and CFRP. Post-curing at 176–248°F increases glass transition temperature (Tg), enabling shear strengths above 20 MPa. Brittle failure may occur at low curing temperatures due to incomplete reactions.

Debondable Adhesives: 17 MPa

Incorporates disulfide (S–S) bonds into a epoxy-based backbone. These adhesives provide high strength under normal use and can be selectively cleaved using a dedicated decomposition solution. They achieve approx.17 MPa after one hour at 160℃, making them ideal for electronic components and battery packs where reworkability and recyclability are required.

Structural Acrylics: 10–22 MPa

Self-curing methacrylate monomers and peroxides form chemical anchors even without surface pretreatment. This makes structural acrylics suitable for high-speed assembly lines. However, due to odor and VOC emissions, work environments and regulations should be checked.

Polyurethane (Two-Part): 7–10 MPa

Forms flexible adhesive layers through a polyol–isocyanate addition reaction. Offers excellent impact resistance and is well-suited for multi-material laminates (e.g., PC + ABS). As moisture reaction can generate CO₂—potentially causing foaming defects—dry application environments are essential.

PUR Reactive Hot Melt: 4–12 MPa

Pellets are melted at 130-150℃ and applied, then undergo moisture-curing to form urethane crosslinks. These adhesives provide rapid initial strength within seconds, making it ideal for high-speed assembly. However, excessive heating reduces viscosity and may cause voids, lowering final strength.

Silicone (RTV): 1–4 MPa

Siloxane-based soft layers offer thermal and weather resistance. RTV Silicone is used for stress-relieving encapsulants in electronics, but its shear strength is relatively low. Potential concerns include hydrolysis in humid conditions and metal contamination due to siloxane bleed.

Methods to Improve Shear Strength of Adhesives

Optimize the Temperature Profile

- ●Epoxy / PUR: Post-cure at Tg + 68°F for 60–120 minutes to maximize crosslink density.

- ●Acrylics: Hold at approx.60℃ to complete polymerization, reduce residual monomers, and increase strength by 15%.

- ●Note: Rapid heating or cooling introduces internal stress. Ideal rate: 2–3℃/min.

Adjust Curing Time (Hold Time)

Monitor reaction progress using Differential Scanning Calorimetry. Maintain heating until residual heat is ≤5% of total. For two-part epoxies, ensure application is completed within the pot life, and gelation occurs within the production cycle.

Control Humidity and Moisture

- ●PUR / Polyurethane: Below 20% RH slows curing; above 70% RH increases foaming risk. Ideal range: 40–60% RH.

- ●Silicone RTV: Both alkoxy and acid cure types are humidity-dependent. Conditioning in controlled environments for 24 hours minimizes strength variation.

Control Pressure and Gap

Shear strength is determined by the effective bonded area multiplied by intermolecular force. Maintain clamping pressure at 0.1–0.2 MPa and keep adhesive thickness within ±10% of design specifications. Use spacers (e.g., glass beads) to stabilize large gaps.

Optimize Mix Ratio (For Two-Part Adhesives)

In epoxy and polyurethane systems, excessive hardener leaves unreacted functional groups, causing brittleness or softening. To mitigate this, maintain resin-to-hardener ratio within ±2% of specification. Use electronic scales or automated dispensers for accurate dosing. Hardener deficiency cannot be corrected with post-curing.

Optimizing five key parameters—temperature, time, humidity, pressure, and ratio—can increase shear strength by up to 30%, even with the same adhesive formula. Start with small-scale lap joint testing (0.98 in × 0.98 in) to identify the optimal curing profile before scaling up for mass production.

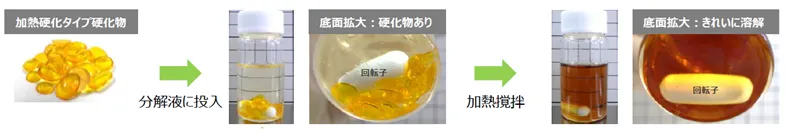

“Easily Debondable Adhesives” That Come Off When You Need Them

Developed by Nagase ChemteX, easily debondable adhesives deliver high bonding performance under normal conditions yet can be cleanly and safely removed under mild conditions using a special decomposition solution—with no harsh chemical solvents. They minimize substrate damage and enhance part recyclability. The decomposition liquid itself is reusable, contributing to environmental sustainability.

These adhesives incorporate reversible disulfide (S-S) bonds into the epoxy network. When immersed in the dedicated solution at ambient temperature below 60°C, these bonds are selectively cleaved, breaking down the molecular chains and dissolving the adhesive.

Key Features

Additional Benefits

- ●Safety: Easily Debondable Adhesives are halogen-free, non-toxic, and solvent-free formulation minimizes workplace risk.

- ●Multi-Material Compatibility: Enables clean separation of metal, resin, and composite interfaces.

- ●Circular Use: Reusable decomposition liquid significantly reduces disposal costs.

- ●Mass Production Ready: Jig-free batch processing (immersion → rinse → dry), suited for applications such as EV battery modules and building materials.

For more information on decomposition mechanisms, available product grades, or operational guidance, please refer to the product introduction page.