How to Remove Pressure-Sensitive Adhesives: Issues in Chemical Solvent Removal

Pressure-sensitive adhesives (PSAs) are used in a wide range of applications, from industrial equipment to consumer goods. However, improper removal methods can leave behind residual tack from the adhesive, which may lead to poor adhesion in subsequent coating or bonding processes, ultimately lowering yield.

This article systematically organizes typical peeling and removal techniques, highlights the specific challenges and selection points when using chemical solvents, and introduces the latest “easily debondable adhesives” as a promising solution to these issues.

Methods for Removing PSAs

Mechanical Removal

This method involves physically scraping off the adhesive using tools such as scrapers, wet blasting, or dry ice blasting. Wet blasting generates minimal static electricity, making it suitable for electrostatically sensitive substrates such as fluoropolymer films or polyimide. It can also modify the surface as part of the treatment.

Depending on the particle size and water pressure, even mirror finishes can be achieved, though care must be taken to avoid polishing irregularities due to nozzle wear. For precision applications, introducing a 3D surface roughness analyzer for in-process measurements is recommended.

Heat Softening

Using infrared heaters or heat guns, adhesives can be softened at temperatures between 60-120 ℃ reducing peel strength and making them easier to remove. Even thick acrylic-based adhesives become significantly easier to peel after heating at around 80 ℃ for a few minutes.

A hybrid method combining spot heating using a soldering iron with a chiller and scraping is also becoming common.

Low-Temperature Brittling

This method uses a cooling spray (−40 ℃) or liquid nitrogen (−196 ℃) to cool the adhesive below its glass transition temperature, promoting brittle fracture. A technique that concentrates stress in gaps of flexible printed circuits (FPCs) to initiate micro-cracks is widely used in smartphone rework processes.

Simultaneous nitrogen purging during cooling helps prevent condensation and oxidation, reducing the risk of flux corrosion in subsequent steps.

Chemical Solvents

In chemical solvent removal, selecting the appropriate solvent based on the adhesive’s Hansen Solubility Parameters (HSP values) is crucial. For instance, for highly polar acrylic-based PSAs, a combination of ester and alcohol solvents may swell the adhesive layer and facilitate removal. When using such solvents, explosion-proof system design is essential, considering flash point, vapor pressure, and ignition temperature.

Work environments should also maintain proper ventilation and exhaust conditions. It’s important to evaluate solvent effects on resin substrates and worker exposure levels (time-weighted average) in advance.

Problems in Removing PSAs with Chemical Solvents

Environmental Issues Upon Disposal

When organic solvents such as toluene are used, incineration of waste solvents releases CO₂ and emits volatile organic compounds (VOCs) into the atmosphere. Common VOC countermeasures include catalytic combustion systems and activated carbon adsorption towers.

Recently, disclosure of carbon footprints based on standards such as ISO 14067 has become more common. Since reducing greenhouse gas emissions directly enhances corporate value, minimizing environmental impact during disposal is critical.

Laborious Disposal Process (Difficult to Sort or Recycle)

Wipes and filters containing PSA sludge often cannot be recycled. Proper disposal requires pretreatment steps such as oil–water separation or solidification. Some facilities install distillation systems to regenerate solvents, though disposing of distillation residues may remain a challenge.

Significant Damage to Substrates

Solvent types can cause material-specific degradation. For example, carbonate solvents may cause stress cracking in polycarbonate (PC), while alkaline solvents can hydrolyze polyethylene terephthalate (PET), leading to yellowing.

In addition, UV-curable clear coats are prone to whitening with ester solvents, potentially affecting both appearance and performance in optical components. To avoid such risks, compatibility tests such as ISO 2812-3 (Solvent Spot Test) should be conducted in advance.

“Easily Debondable Adhesives” Solving Solvent-Based Adhesive Removal Issues

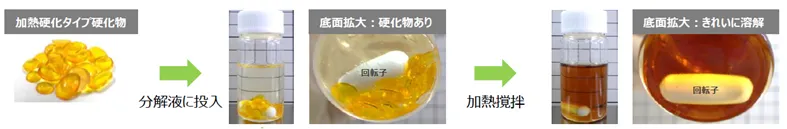

Developed by Nagase ChemteX, easily debondable adhesives deliver high bonding performance under normal conditions yet can be cleanly and safely removed under mild conditions using a special decomposition solution—with no harsh chemical solvents. They minimize substrate damage and enhance part recyclability. The decomposition liquid itself is reusable, contributing to environmental sustainability.

These adhesives incorporate reversible disulfide (S-S) bonds into the epoxy network. When immersed in the dedicated solution at ambient temperature below 60°C, these bonds are selectively cleaved, breaking down the molecular chains and dissolving the adhesive.

Key Features

Additional Benefits

- ●Safety: Easily Debondable Adhesives are halogen-free, non-toxic, and solvent-free formulation minimizes workplace risk.

- ●Multi-Material Compatibility: Enables clean separation of metal, resin, and composite interfaces.

- ●Circular Use: Reusable decomposition liquid significantly reduces disposal costs.

- ●Mass Production Ready: Jig-free batch processing (immersion → rinse → dry), suited for applications such as EV battery modules and building materials.

For more information on decomposition mechanisms, available product grades, or operational guidance, please refer to the product introduction page.