Methods for Adhesive Decomposition and Types of Recycling

Adhesive Layers as Bottlenecks in Resource Recovery—and How to Overcome Them

In industries such as electronics and automotive manufacturing, non-decomposable adhesive layers often hinder effective resource recovery.

Many companies face challenges such as:

- ●“We want to improve the recovery yield of high-value components.”

- ●“We need to reduce disposal costs and build a sustainable circular process.”

The key to solving these issues lies in combining effective adhesive decomposition with recycling strategies.

This article classifies decomposition approaches into four main types and outlines the most suitable recycling schemes for each.

Using Decomposition to Break Down Adhesives

Physical and Thermal Decomposition

Physical decomposition involves the mechanical breaking of adhesive layers through shear, impact, or abrasion. Some examples are:

- ●Scrapers and stripping blades: Effective for thin rubber-based adhesive films

- ●Sandblasting/dry ice blasting: Ideal for complex shapes or removing oxide layers

- ●Water jetting (300 MPa): Rapid removal of thick polyurethane resin layers or coatings with minimal dust

Thermal decomposition typically involves pyrolysis in a 662–932°F furnace to volatilize and carbonize organics. While it enables full recovery of metals from plastic- or rubber-containing parts (e.g., auto components), it also entails high energy consumption and complex maintenance due to residue buildup on furnace walls.

Chemical Decomposition (Depolymerization)

Chemical decomposition breaks polymer chains through targeted reactions, recovering monomers or oligomers.

By designing selective catalysts, specific bonds such as esters and carbamates can be cleaved, and the resulting monomers can be distilled and purified for repurposing into new resins.

To minimize side reactions, nitrogen purging and filtration of residues are essential.

Reversible or Degradable Polymer Network Decomposition

This type of decomposition is an innovative method using stimuli-responsive polymers, allowing controlled depolymerization under mild conditions. Examples are:

- ●Disulfide (S-S) bonds: Cleaved via reduction

- ●Diels–Alder bonds: Reversible; dissociation at 120℃, recombination below 80℃

- ●Imine bonds (-C=N-): Responsive to pH changes

Easily debondable adhesives incorporating such networks offer 15–20 MPa shear strength under normal use yet can be untangled at just 60℃, preserving base materials such as aluminum die cast or carbon fiber reinforced polymer laminates for reuse.

Biodegradation

This approach uses biodegradable polymers (e.g., polylactic acid (PLA), polybutylene succinate and polycaprolactone) as binders, which are hydrolyzed by microbes or enzymes. Some examples are:

- ●Enzymatic bath: Using 1% by weight lipase solution at 50℃ for 24 hours results in >95% mass loss.

- ●Composting: Breaks down adhesive over 6–8 weeks at 55℃ and high humidity.

Already in use for medical sutures and agricultural seedling pots, this method is energy-efficient—requiring less than 1/10th the energy of thermal decomposition.

Recycling Strategies Based on Decomposition Methods

Physical/Thermal Decomposition: Downcycling

The residuals are porous carbonized material or powder, losing original resin functionality. Examples are:

- ●Energy recovery: Used as fuel for cement kilns or waste-heat recovery

- ●Filler reuse: In road paving or insulation materials

Metal substrates can be recovered efficiently, but the adhesive is treated as fuel, not material. While it helps reduce CO₂ emissions, true material circularity remains limited.

Chemical Decomposition: Closed-Loop Recycling

Recovered monomers enable a closed-loop cycle:

Raw material → Resin → Product → Raw material

Examples are:

- ●Epoxy → Bisphenol A: Reused in new epoxy with ≥99% purity

- ●Polyurethane foam → Polyols: Recycled into self-adhesive foams

Compared to virgin materials, this can cut CO₂ emissions by up to 60%. However, it requires high-capital-expenditure equipment capable of operating above 200℃ and under pressure.

Reversible Network Decomposition: High Substrate Reuse Rate

Low-temperature decomposition allows the reuse of both adhesives and substrates. The process is as follows:

- S-S bond cleavage via decomposition solution → Adhesive becomes thermoplastic

- Substrate recovered intact → Sent for cleaning and rebuilding

- Decomposition liquid distilled under vacuum → Recycled into the next debonding process

Biodegradation: Biological Closed Loop

Biodegradation products are metabolized into biomass carbon and reused as fermentation feedstock. Examples are:

- ●Lactic acid fermentation → PLA synthesis → Biodegradation → Lactic acid

- ●Acetic acid fermentation → Polyhydroxyalkanoates synthesis → Biodegradation → CO₂ + H₂O → Photosynthesis

This contributes to carbon neutrality and reduces reliance on fossil resources.

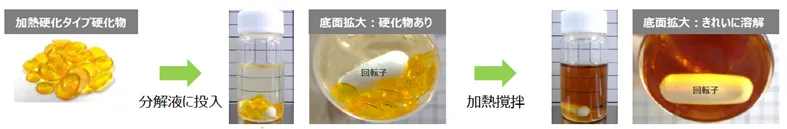

Enabling Part Reuse with Easily Debondable Adhesives

Developed by Nagase ChemteX, easily debondable adhesives deliver high bonding performance under normal conditions yet can be cleanly and safely removed under mild conditions using a special decomposition solution—with no harsh chemical solvents. They minimize substrate damage and enhance part recyclability. The decomposition liquid itself is reusable, contributing to environmental sustainability.

These adhesives incorporate reversible disulfide (S-S) bonds into the epoxy network. When immersed in the dedicated solution at ambient temperature below 60°C, these bonds are selectively cleaved, breaking down the molecular chains and dissolving the adhesive.

Key Features

Additional Benefits

- ●Safety: Easily Debondable Adhesives are halogen-free, non-toxic, and solvent-free formulation minimizes workplace risk.

- ●Multi-Material Compatibility: Enables clean separation of metal, resin, and composite interfaces.

- ●Circular Use: Reusable decomposition liquid significantly reduces disposal costs.

- ●Mass Production Ready: Jig-free batch processing (immersion → rinse → dry), suited for applications such as EV battery modules and building materials.

For more information on decomposition mechanisms, available product grades, or operational guidance, please refer to the product introduction page.