Adhesive for post vulcanization rubber

Achieving adhesion to vulcanized rubber with a "solvent-free" system Resolving the previously difficult task of bonding to vulcanized rubber using a one-coat adhesive

Advantages and implementation effects

Advantages of adhesive for post vaulcanization adhesion

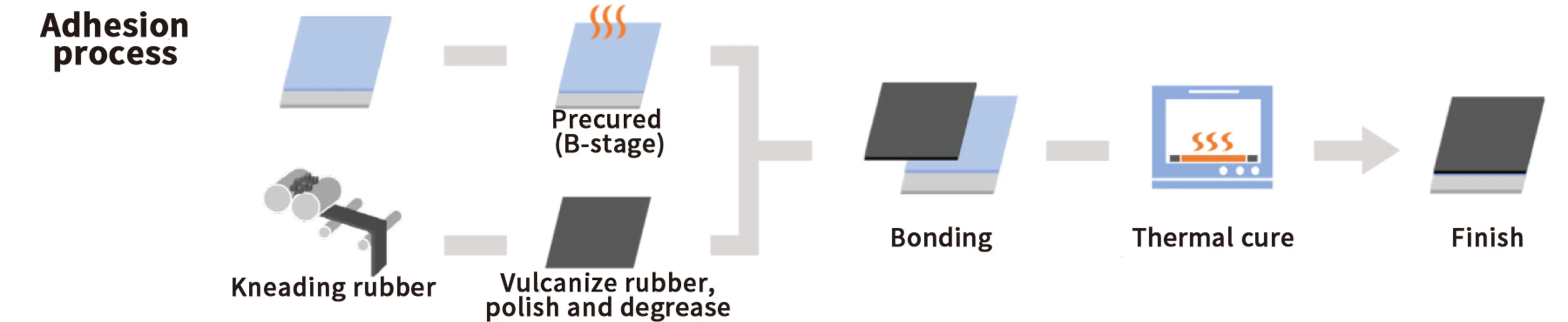

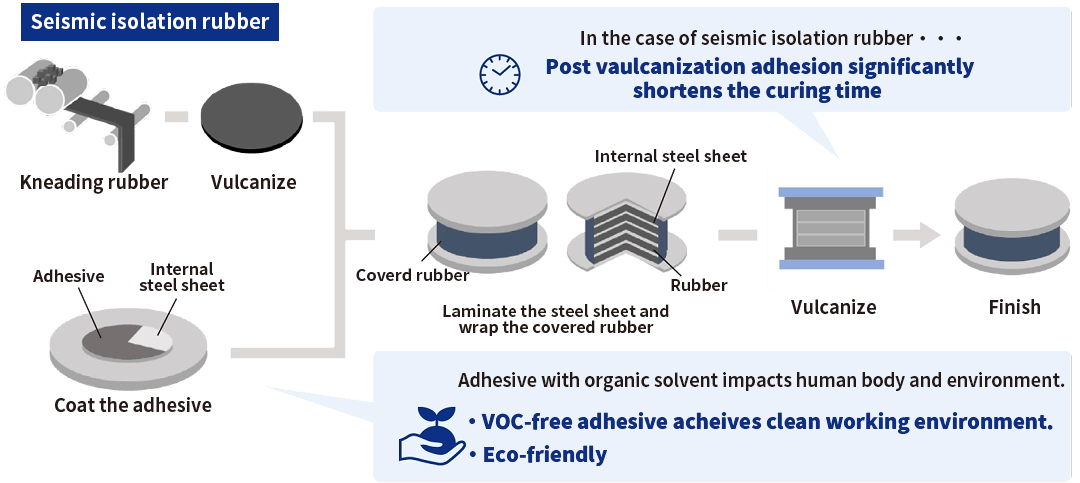

- Post vulcanization adhesion

-

Bonding post vulcanization rubber to a substrate

- ・If the rubber is vulcanized at once, it can be stored as rubber stock.

- ・Adhesion does not require large presses or molds, and curing time can be shortened.

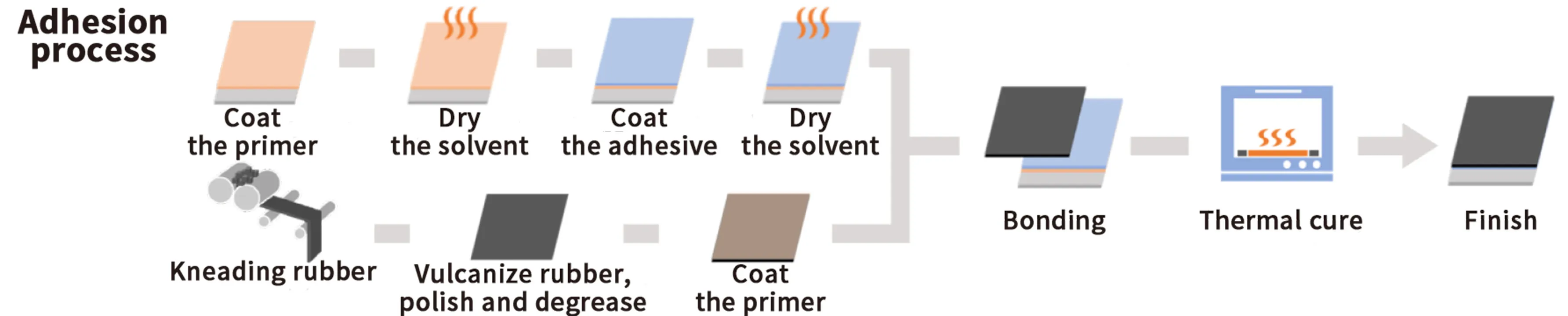

- vulcanization adhesion

-

Bonding simultaneously with vulcanization

- ・Rubber before vulcanization tends to bleed or crystallize, requiring re-kneading before use.

- ・Large press machines are required when molding large parts.

- ・Mold temp control takes time.

Implementation advantages of this product

- Our product

-

- ・One-coat type that does not require primer treatment, enables a reduction in process steps and time.

- ・It is a VOC-free type, making it both human- and environmentally- friendly.

- General post-vulcanization adhesion

-

- ・Conventional post-vulcanization adhesives require primer treatment for both metal and rubber.

- ・It contains organic solvents, which are harmful to both humans and the environment.

Application example for seismic isolation rubber

It is possible to shorten the process while considering the environment.

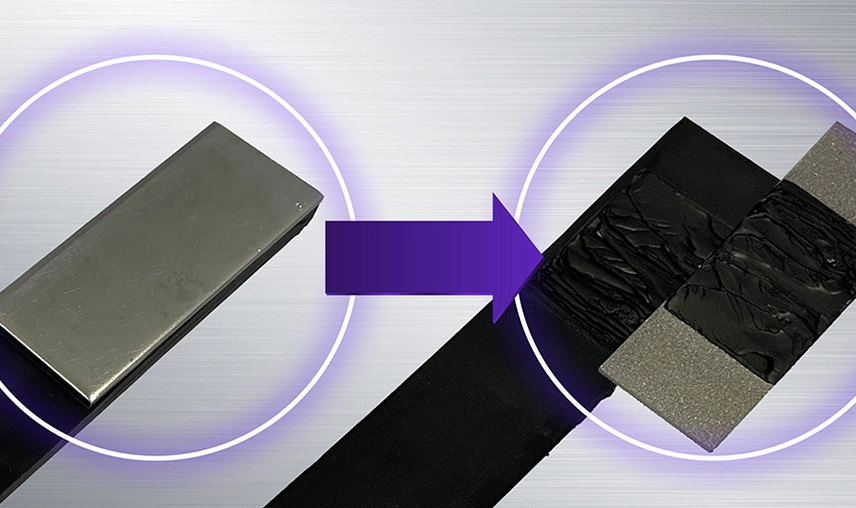

Post vulcanization rubber adhesives achieve equivalent stregth to conventional vulcanized adhesion process.

<Applicable materials>Rubber:NR、BR、NBR etc. Metal:SPCC、Al etc.

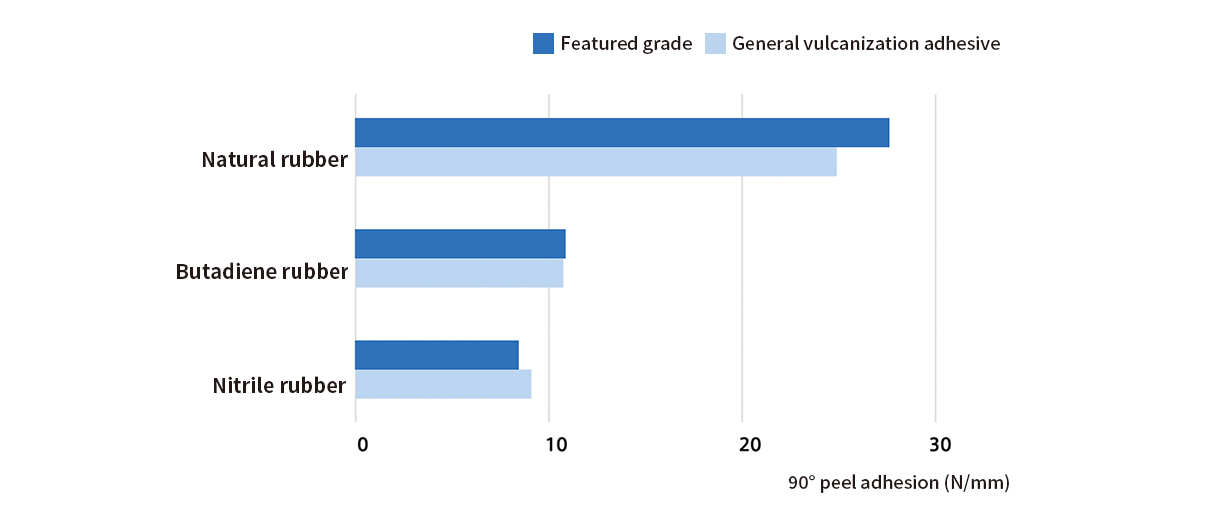

Comparison of adhesion with various rubbers(SPCC-Rubber)

Comparison of adhesion with various rubbers(SPCC-Rubber)

Test results

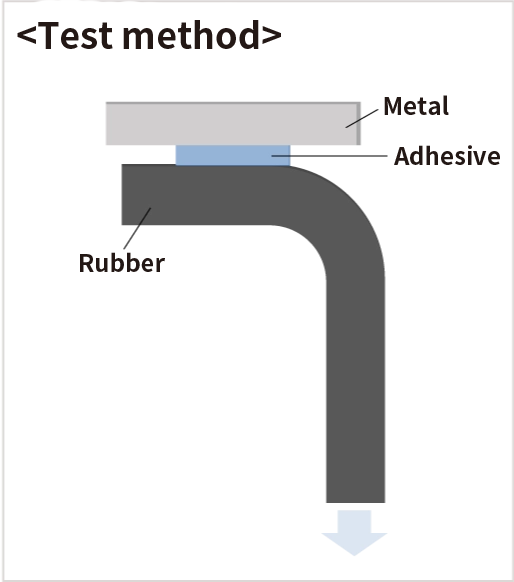

Test of 90° peel adhesion

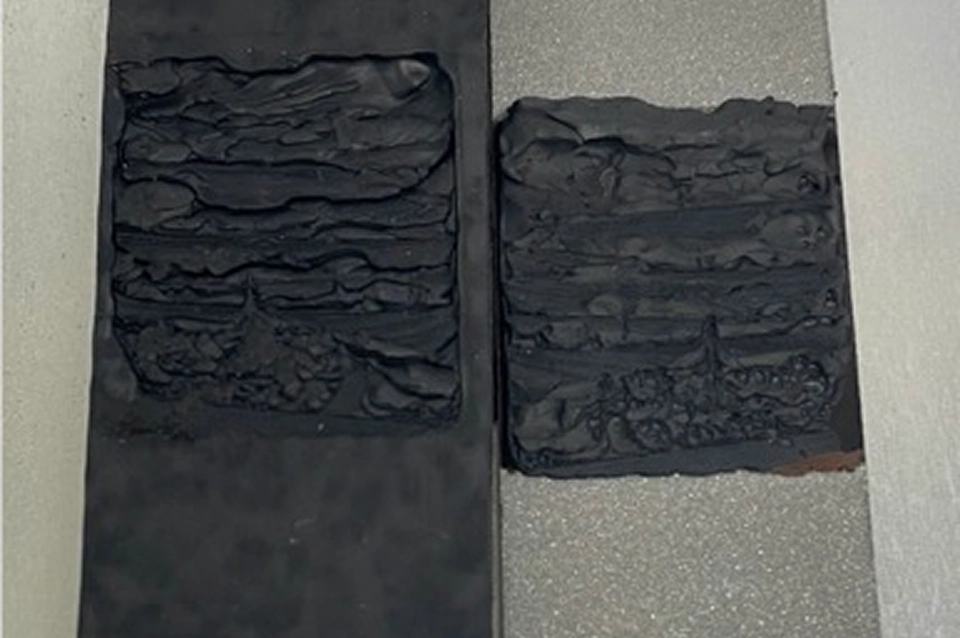

Adhesive strength from the cross-section of adhesion tests

By observing the fracture surface after adhesive testing, the failure mode can be determined.

In the adhesion of rubber to metal, it is considered that the adhesive strength is strong when the rubber itself is broken during peeling.

Adhesive properties

| Item | Characteristic values |

|---|---|

| Appearance | Brown liquid |

| Curing conditions | 150℃ / 1hr. |

| Viscosity(25℃) | 15Pa・s |

| Glass transition temp | 144℃ |

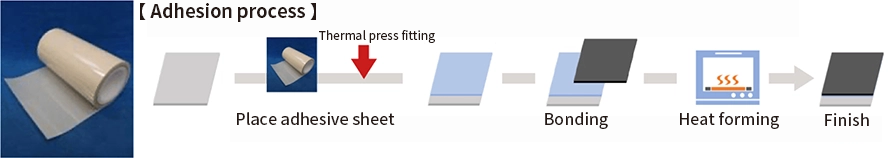

Available product forms

- Sheet-type (Under development)

-

- ・The sheet-type has a uniform thickness.

- ・It can be applied evenly on large-area substrates, improving quality stability.

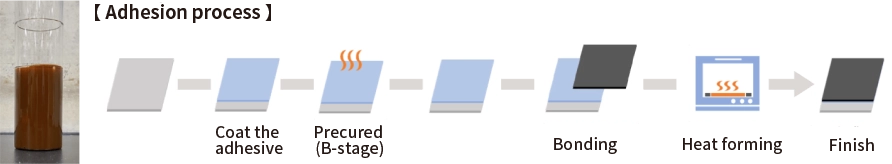

- Liquid-type

-

- ・Uniform application without unevenness on large-area substrates requires technical expertise.

Application exapmles

Seismic isolation rubber for construction

Mobility