DENACOL: A Fiber Treatment Agent That Enhances Textile Performance

Fiber Treatment Agent: DENACOL

We would like to introduce you to DENACOL, a product Nagase ChemteX has developed and refined over many years.

Applications as a Fiber Treatment Agent

DENACOL can be used as a textile treatment agent because it chemically bonds (crosslinks) with the hydroxyl groups in cellulose fibers, stabilizing the fiber structure and making it less prone to wrinkling. It can be widely applied to frequently used textile products such as handkerchiefs and shirts, as well as delicate materials like cotton.

Cotton, as a natural fiber, has high water absorbency but tends to wrinkle easily because it swells when wet and shrinks during drying. Using DENACOL is expected to impart and improve wrinkle resistance, addressing this weakness of cotton fibers.

Features

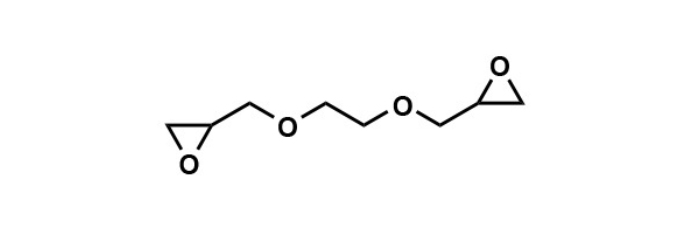

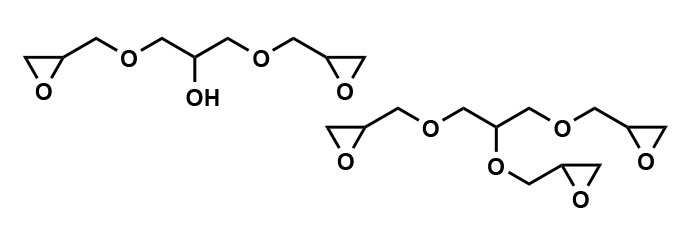

DENACOL is the collective name for specialized epoxy compounds created through advanced organic synthesis technology that convert alcoholic hydroxyl groups and organic acids into glycidyl ethers (or esters).

The epoxy groups in DENACOL act as effective cross-linking agents, making it useful not only as a fiber treatment agent but also in various other applications, such as::

- Acrylic resin cross-linkers

- Adhesives

- Resin stabilizers

- Resin modifiers

- Flexibility enhancers

- Reactive diluents

Recommended Grades

DENACOL offers three recommended grades that can be used as fiber treatment agents. These products are characterized by their water solubility and low viscosity, making them ideal for applications requiring softening, hydrophilic properties, and surface treatment of fibers.

EX-1810

Chemical name: Ethylene glycol diglycidyl ether

SWIPE

| Epoxy equivalent (g/eq.) |

Viscosity (mPa·s) |

Total chlorine content (%) |

Color value (APHA) |

Water solubility (%) |

Packaging |

|---|---|---|---|---|---|

| 113 | 20 | 0.6 | 20 | 100 | 20kg, 220kg |

EX-313

Chemical name: Glycerol polyglycidyl ether

SWIPE

| Epoxy equivalent (g/eq.) |

Viscosity (mPa·s) |

Total chlorine content (%) |

Color value (APHA) |

Water solubility (%) |

Packaging |

|---|---|---|---|---|---|

| 141 | 150 | 9 | 10 | 99 | 20kg, 220kg |

For those interested in using Denacol as a fiber treatment agent.

Nagase ChemteX’s specialized epoxy compound “DENACOL” can effectively impart wrinkle resistance to cotton and other fibers.

Please follow the links below for detailed information tailored to your company’s specific needs.

Basics of Textile Treatment Agents

In the textile industry, proper fiber treatment is essential for producing high-quality products. DENACOL, developed and manufactured by Nagase ChemteX, is used as a fiber treatment agent and makes a significant contribution to improving the quality of textile products.

What is a Fiber Treatment Agent?

Fiber treatment agents are chemical substances used to enhance the performance and quality of textile products. It is used during the manufacturing process and plays an important role in enhancing the value of the final product by imparting various functional properties.

Main Purposes of Fiber Treatment

Fiber treatment’s purposes vary widely depending on the product’s intended use and required performance characteristics. Effective treatments add necessary functionality while preserving the fiber’s inherent properties. Here are four representative examples:

Improving Mechanical Properties

Enhancing the fibers’ mechanical properties directly impacts product durability and feel. By increasing fiber strength, the overall durability of the final product improves significantly. Adding appropriate elasticity and flexibility enhances wearing comfort, while reinforcing the fiber surface increases resistance to everyday wear and abrasion, contributing to extended product lifespan.

Because many garments are worn daily, consumers seek affordable yet durable products. Fiber treatment enables the manufacturing of products with superior mechanical properties capable of withstanding regular consumer use.

Improving Surface Properties

The surface properties of fibers significantly impact both manufacturing processes and the final product’s tactile qualities. Surface treatments that smooth fibers enhance efficiency during weaving operations. When fiber-to-fiber friction is properly controlled, the product’s overall texture and feel noticeably improves. Surface treatments are particularly important when working with composite materials or applying coatings as improved adhesion results in more durable finished products.

Fiber surface roughness also plays a crucial role in static prevention, as mentioned below. Optimizing surface characteristics according to specific applications and consumer needs is essential for enhancing comfort and wearability and for preventing static electricity buildup.

Chemical Modification

Chemical modification treatments effectively impart functional properties, such as water repellency and flame resistance. Flame retardancy is particularly crucial for welding overalls used in environments where sparks may fly.

In the dyeing process, these treatments enhance dye permeability, resulting in more vibrant colors while preventing discoloration during long-term use. Improved permeability offers environmental benefits by reducing the amount of dye needed to achieve desired shades, consequently decreasing wastewater treatment requirements.

Fibers with low permeability typically leave more unreacted dye in effluent, whereas higher permeability allows for more efficient dyeing with less dye, contributing to cost reduction.

Improved Hygiene and Comfort

Modern textile products demand high standards in both hygiene and comfort. Treating fibers with antibacterial properties inhibits bacterial growth, preventing unpleasant odors. This is particularly valuable for children, who tend to perspire more and have sensitive skin that is prone to irritation. Hygienic clothing is also important for adults troubled by odors from bacteria in sweat-prone garments, like underwear and socks—making clean clothing an important consideration for social etiquette.

Fiber treatments enhance moisture-wicking and quick-drying properties for rapid perspiration absorption and dispersal to improve wearing comfort. Additionally, improved insulation creates comfortable wearing experiences regardless of season. In Japan’s hot and humid climate, underwear with superior quick-drying and insulating properties is especially practical.

Functionalization by using fiber treatment agents

Water repellency

When treated with water repellent agents, fibers develop a water-repelling layer on their surface. This treatment prevents the fibers from absorbing moisture and enhances the product’s water resistance. For high-performance sportswear requiring quick-drying properties, water repellency and water resistance are essential performance characteristics.

These treatments also prevent moisture-related fiber deterioration, maintaining product quality over extended periods. Additional benefits include easier stain removal and mold prevention, significantly extending the garment’s useful lifespan.

UV resistance

UV radiation can dramatically shorten a product’s lifespan by degrading the fibers. UV treatments enhance fiber resistance to ultraviolet light, preventing sun-induced discoloration and strength reduction. This feature is particularly critical for products used outdoors or those frequently exposed to sunlight.

Many items—such as sportswear and construction workwear—are continuously exposed to UV radiation during use. Since these are practical rather than decorative items, they require long-term durability in challenging environments.

Softeners

Softening treatments provide textiles with optimal flexibility. This enhances the product’s tactile qualities and delivers superior wearing comfort. In garments where texture is important, such as sweaters, maintaining flexibility over time helps preserve the product’s value.

Additionally, by reducing friction between fibers, these treatments enhance overall product durability. This dual benefit improves both the garment’s performance characteristics and extends its useful lifespan.

Antistatic

Static electricity causes handling difficulties and discomfort in textile products. Antistatic treatments improve the surface conductivity of fibers and prevent static buildup. These treatments effectively eliminate uncomfortable static shocks.

A major advantage of antistatic treatment is its ability to prevent pollen adhesion. Likewise, it reduces dust accumulation, helping garments stay cleaner for longer periods.

Anti-Wrinkle

Wrinkles are one of the main factors that detract from the appearance of textile products. Wrinkle-resistant treatments help fibers become less prone to wrinkling, allowing garments to maintain a consistently clean and smooth appearance.

For example, while dress shirts can be ironed to remove wrinkles, frequent use often creates a need to reduce the time and effort spent on ironing. Applying wrinkle-resistant agents to such garments can suppress the formation of wrinkles or make them easier to smooth out, thereby making daily care easier and enhancing overall convenience.

Inquiries and Sample Requests

For more information or sample requests, please feel free to contact us.