Effectiveness of DENACOL in Paint Applications |Crosslinker Comparison Experiment

One of the typical uses of DENACOL is as a cross-linker in paints.

In this study, we conducted experiments on the effects of DENACOL in paint applications.

First, when DENACOL is used as a cross-linking agent in paints, the following effects are obtained.

- Improved adhesion to substrates

- Improvement of water resistance of coated film

- Improvement of solvent resistance of the coated film

- Improvement of substrate adhesion

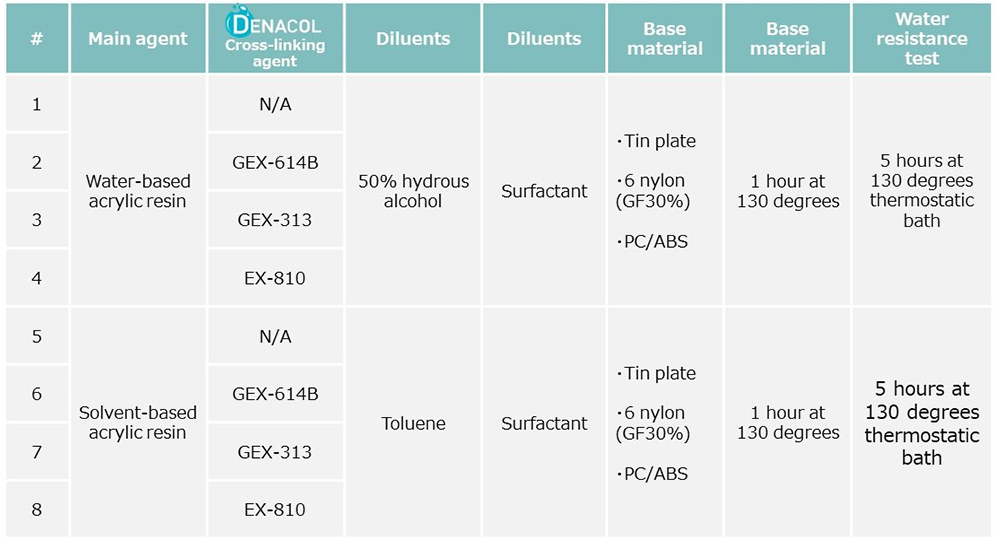

This time, we conducted an experiment to see how much the adhesion and water resistance would change with and without the addition of DENACOL.

The DENACOL used are EX-614B, EX-313, and EX-810.

Film Deposition Conditions and Test Methods

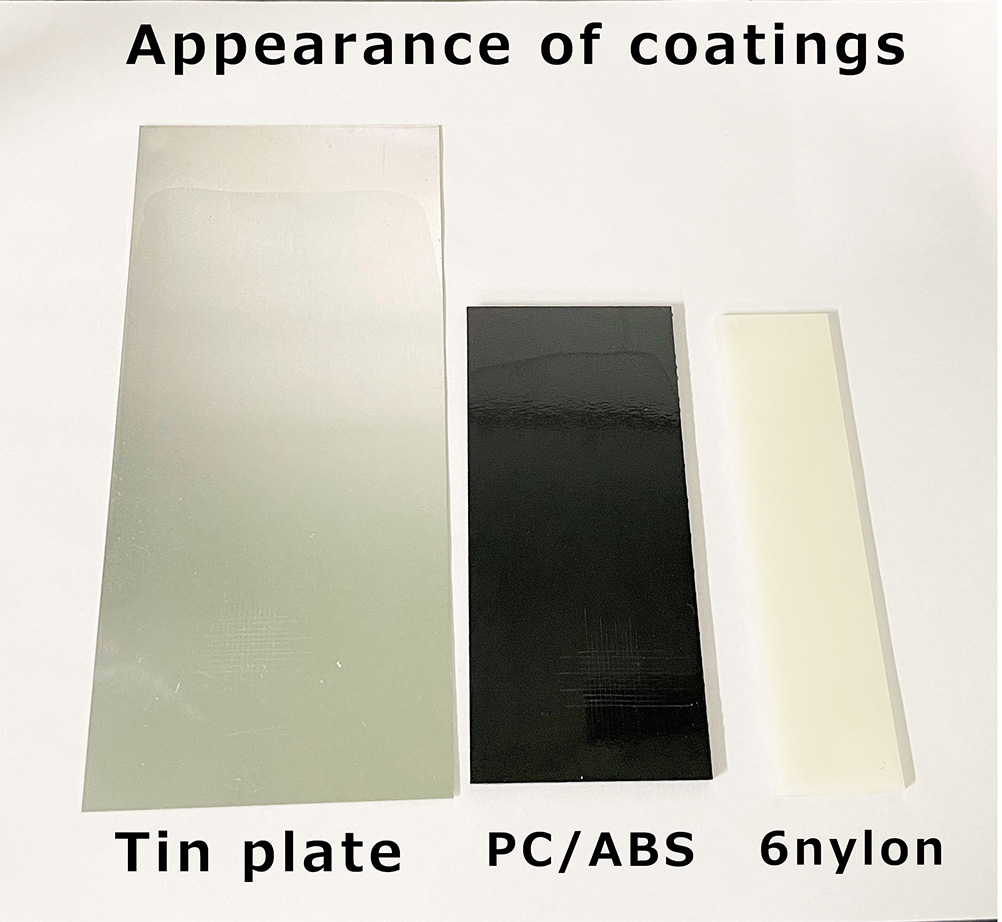

Base material: Tinplate, PC/ABS, 6 nylon

Coating thickness: Dry 10 μm (bar coater)

Drying conditions: 130°C x 1hr (air dryer)

Water resistance test: immersion in 60°C water bath for 5 hours

The film is deposited with a bar coater, dried with an air dryer, and then tested for adhesion with a grid test.

After that, a water resistance test was conducted to confirm the appearanceand an adhesion test was conducted with a board test.

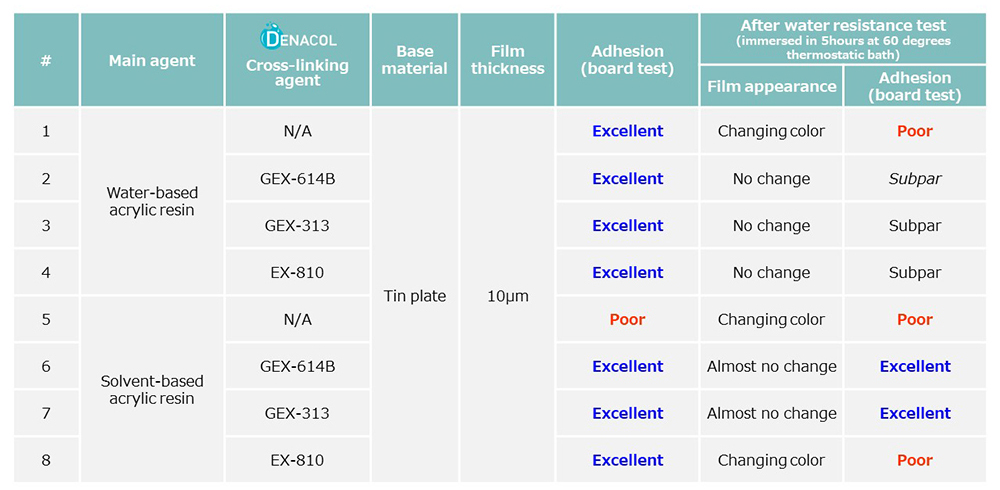

Tinplate base material

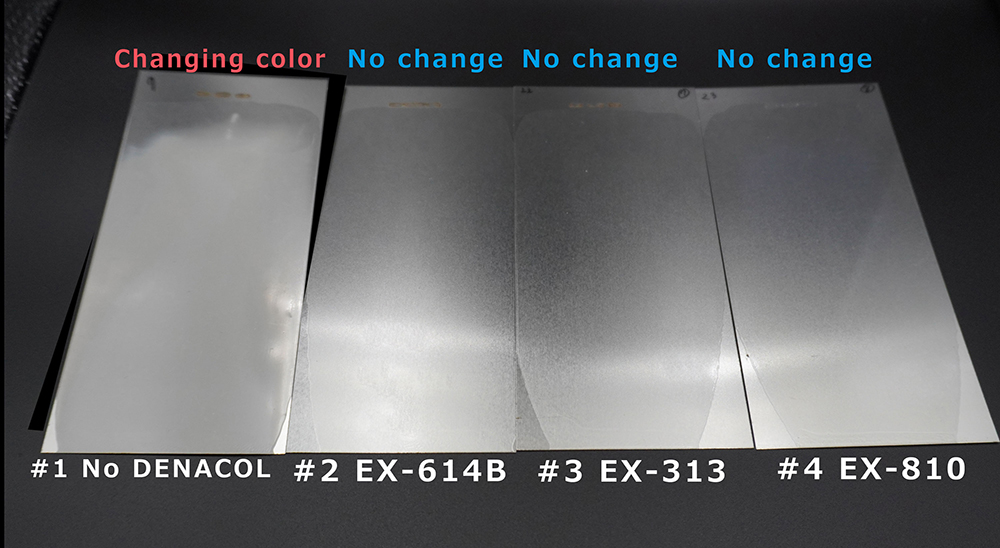

Initial adhesion of tinplate was better with "with DENACOL added" than "without DENACOL added". In a subsequent water resistance test, the appearance of "without DENACOL addition" changed significantly.

The solvent-based products with the addition of EX-614B and EX-313 also showed excellent adhesion after the water resistance test.

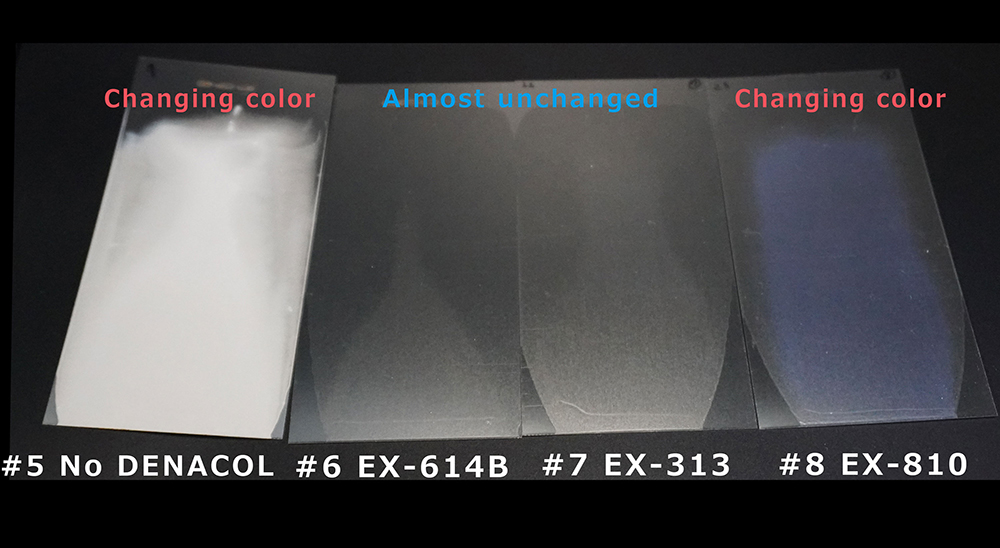

Photo after water resistance test

Water-based

Solvent-based

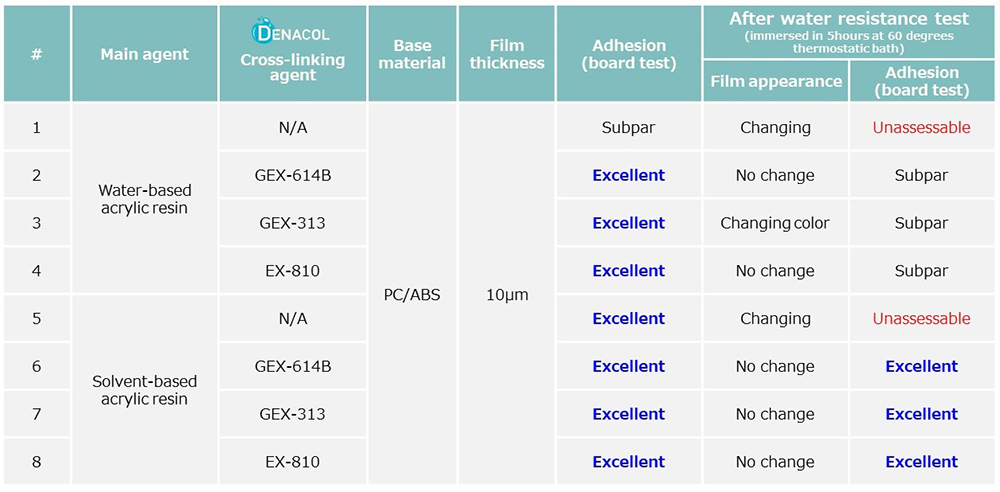

PC/ABS base material

The initial adhesion of PC/ABS was almost clear with or without the addition of DENACOL, but the water resistance test conducted afterward showed that "without DENACOL addition" dissolved and the appearance changed significantly.

In the subsequent water resistance test, the film without DENACOL addition dissolved, resulting in a significant change in appearance.

For the solvent-based EX-614B, EX-313, and EX-810 additives, good results were also obtained in terms of adhesion after water resistance testing.

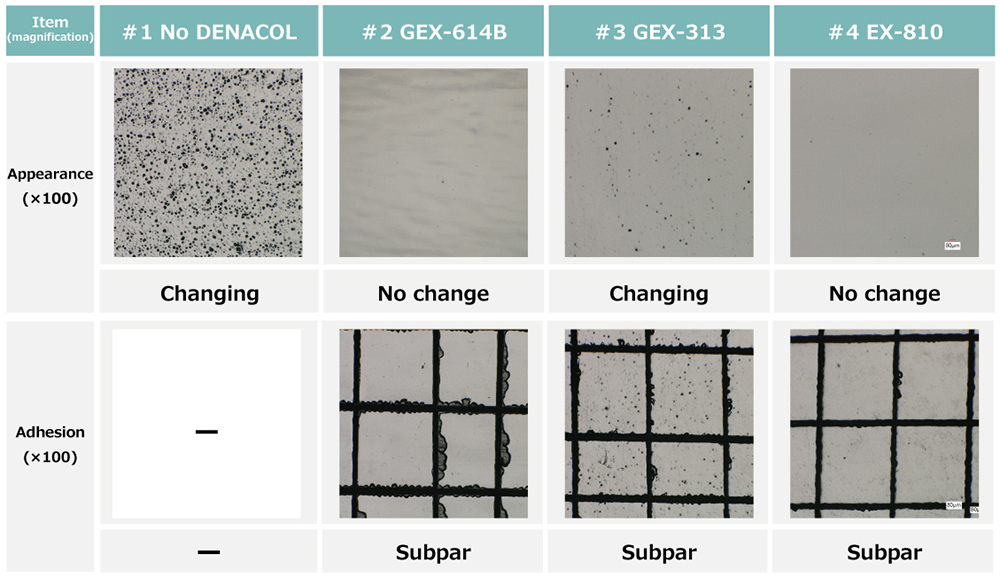

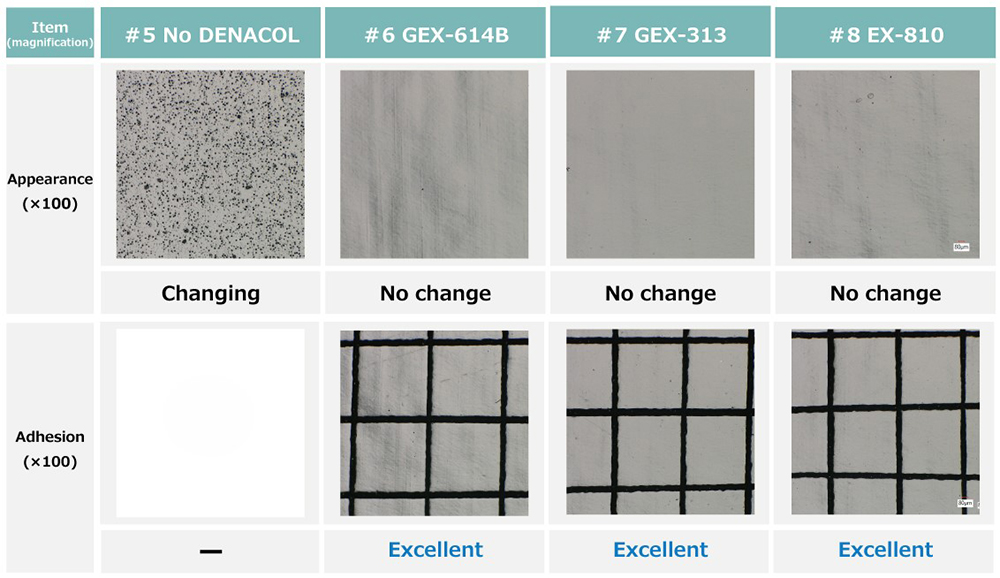

Optical microscopic observation after water resistance test

*PC/ABS base materials are compared with optical microscope images because it is difficult to see the difference in the photos.

Water-based

Solvent-based

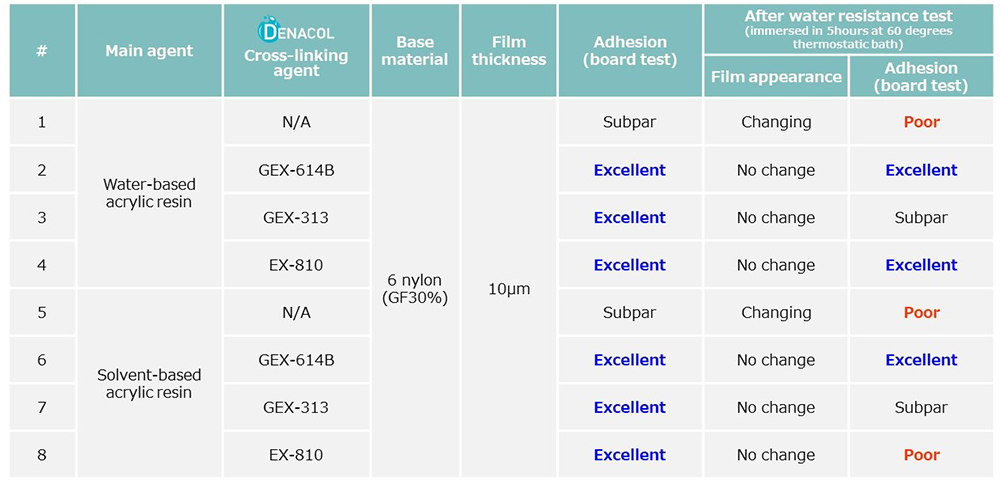

6 nylon (GF30%) base material

The initial adhesion of 6 nylon with DENACOL was superior to that of 6 nylon without DENACOL. In a subsequent water resistance test, the coating film without DENACOL swelled and changed in appearance.

The water-based products EX-614B, EX-313, and EX-810 and the solvent-based products with the addition of EX-614B and EX-313 also showed excellent adhesion after the water resistance test.

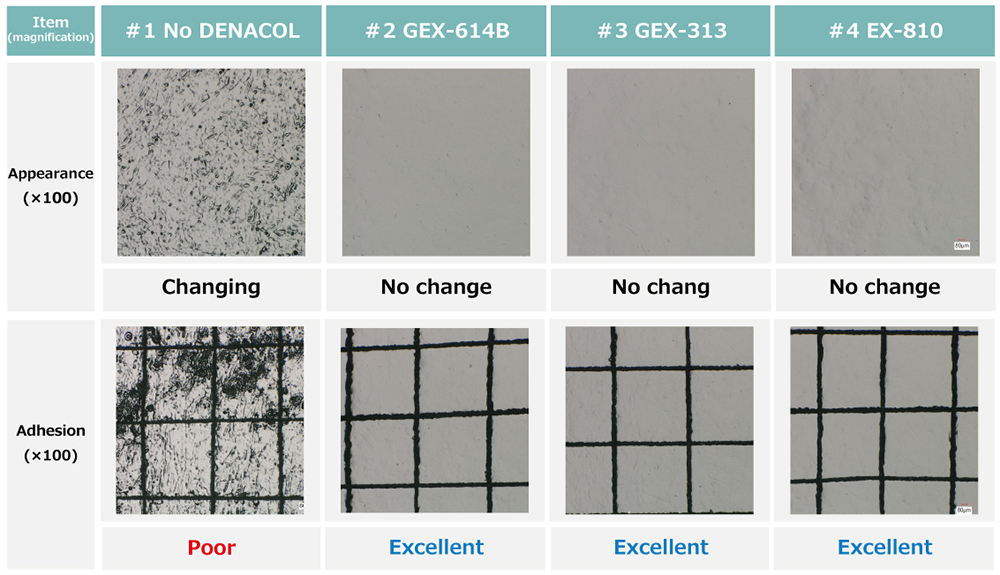

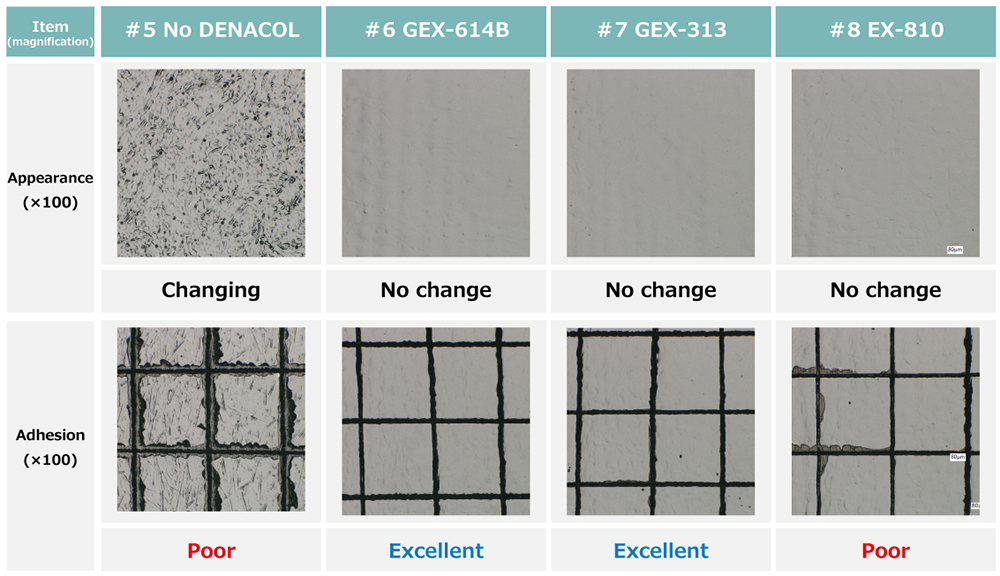

Optical microscopic observation after water resistance test

*Because it is difficult to see differences in nylon substrates in photographs, optical microscope images are used to compare the two materials.

Water-based

Solvent-based

Three base materials were selected and tested with and without DENACOL, and the initial adhesion was superior with the addition of DENACOL.

In subsequent water resistance tests, the addition of DENACOL improved water resistance and adhesion in some cases.

As you can see, we hope you have found that both water-based and solvent-based products can be used as cross-linking agents.

Although there are differences depending on the base material used and the grade of DENACOL product selected, we can propose the optimal DENACOL product for the environment in which it will be used.

For questions about our products or to request a sample, click here.