Water-Soluble Epoxy Explained for Industry Professionals

What is Water-Soluble Epoxy Resin?

Water-soluble epoxy resins have gained attention in recent years because they offer improved environmental protection and safety. Bisphenol A type and cresol novolac type epoxies are commonly used as general epoxy resins. It is mainly used as a cross-linking or surface-modifying agent and is employed in items such as textiles, paper, paint and adhesives.

There are various types of water-soluble epoxy resins, each with different properties in terms of solubility in water, epoxy content, and viscosity. Therefore, it is necessary to use the type that is best suited for the intended application and purpose.

How Does it Function?

(Why Does Water-Soluble Epoxy Resin Dissolve in Water?)

Water-soluble epoxy resins contain hydrophilic polar groups such as ether groups within their molecules. Generally, resins called water-soluble polymers have many hydrophilic polar groups along their main chain, allowing these large molecules to dissolve in water. There are different types of hydrophilic polar groups, including hydroxyl groups (-OH), carboxyl groups (-COOH), amino groups (-NH2), and sulfonic groups (-SO3H). The variety, number, and distribution of these polar groups affect the water solubility.

When water-soluble polymers are placed in water, the hydrophilic groups hydrate with water molecules, and these molecules intervene with a force greater than the attraction between the polymers, causing swelling. When this swelling occurs indefinitely, the polymer is considered dissolved in water.

Advantages of Using Water-Soluble Epoxy Resins

Environmental Benefits

Using water-soluble epoxy resin can reduce volatile organic compound (VOC) emissions. VOC is a general term for organic compounds that become gaseous in the atmosphere and are considered to have a negative impact on the atmospheric environment, such as causing photochemical smog. The amount of VOC emissions from paints is currently greater than from other sources. In the work environment, VOCs are a concern for health reasons.

Therefore, there are various legal regulations for the use of VOCs, and it is necessary to comply with laws such as the Clean Air Act and the Occupational Safety and Health Act.While organic solvents dissolve resins easily, they can have a negative environmental impact, which is why VOC-free initiatives are actively being pursued.

High Versatility

Water-soluble epoxy resin, with its diverse reactivity, can be utilized for various purposes. When water-soluble epoxy is made from polyvalent alcohols such as glycerin or polyglycerin, it not only has a high affinity for water but also forms multifunctional epoxy compounds, resulting in rapid curing properties. By utilizing these properties, coating agents have been developed.

Performance Advantages

Using water-soluble epoxy resin can improve adhesion, corrosion resistance, and chemical resistance. Generally, adhesives that blend well (wet) with the surface of the substrate will have increased adhesive strength. If the substrate is hydrophilic, water-soluble epoxy resin will have a high level of affinity and blend with the surface, resulting in strong adhesion.

Furthermore, when water-soluble epoxy resin is applied as a coating agent on metal surfaces, it can impart hydrophilicity to the solid surface and prevent corrosion caused by adherent droplets. In addition, by changing the structure and composition of the epoxy compound, an improvement in chemical resistance can be expected.

Applications of Water-Soluble Epoxy

Floor Coating

Water-soluble epoxy can be used as floor coating. The coating agents used for floor coatings are paints, including solvent-based, solvent-free, and water-based paints. Water-soluble epoxy can be used as a floor coating agent that can be expected to be durable and reduce VOCs, making it friendly to indoor environments.

Fabric Finishing

Fabric finishing is a textile treatment that provides properties such as wrinkle resistance to shirts and handkerchiefs. Water-soluble epoxy resin can be used as a textile treatment agent. It cross-links the hydroxyl groups of fibers (cellulose) and fixes the structure, making the textile less prone to wrinkling.

Adhesives

Epoxy resin adhesives generally have excellent electrical characteristics, mechanical properties, adhesion to substrates, chemical resistance, water resistance, heat resistance, and dimensional stability. They are widely used as adhesives in electrical/electronic devices, civil construction, transportation equipment, and shipbuilding industries.

Water-Soluble Epoxy Resin, DENACOL

What is DENACOL?

DENACOL is a specialty epoxy compound developed by Nagase ChemteX. It is made by glycidyl etherification (esterification) of alcoholic hydroxyl groups with carboxylic acids. Nagase ChemteX offers a range of products, from mono-functional to multi-functional epoxies, with a particular emphasis on water-soluble epoxy compounds. These compounds can be used in a wide range of applications due to the high reactivity of the epoxy group.

Features

DENACOL water-soluble epoxy resin can be used for various water-based treatment applications. It is soluble in not only water but also solvents and can be used as a cross-linking agent in multiple systems. Furthermore, it is VOC-free, making it an environmentally low-impact product.

Types

This section introduces the representative grades of DENACOL water-soluble epoxy resin. Each type has more than 90% water solubility, and you can choose according to your purpose and application.

Multi-functional type

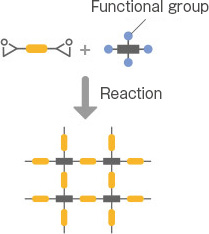

These are multi-functional epoxy compounds such as sorbitol and glycerin, which can be used as cross-linking agents for resins, adhesion improvers for paints, and modifiers for fibers and paper. They are suitable for water-related work, such as the manufacturing of fibers and paper.

Major Grades:

EX-614B

EX-313

EX-512

Di-functional type

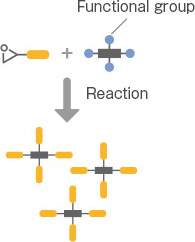

These epoxy compounds are based on polyethylene glycol, polypropylene glycol, and similar polymers. They are used as high water-soluble cross-linking agents and resin modifiers. Many have low viscosity and can also be widely used as reactive diluents.

Major Grades:

EX-810

EX-861

Mono-functional type

These are mono-functional epoxy compounds such as lauryl alcohol (EO) 15 glycidyl ether, which are used as reactive diluents, resin stabilizers, and similar substances.

Major Grades:

EX-171

GREEN DENACOL

These are bio-based epoxy compounds made from plant-derived raw materials. By switching from traditional petroleum-based (exhaustible resource) raw materials to bio-based (plant-derived), we have realized the manufacture of sustainable epoxy cross-linking agents. They contribute to the reduction of CO2 emissions through photosynthesis of the raw material by plants.

Major Grades:

EX-313

EX-512

EX-521

EX-614B

Related questions

What is waterborne epoxy?

Waterborne epoxy means water-based epoxy and is different from water-soluble epoxy. Waterborne epoxy uses water as a solvent.

What are hydrophilic and hydrophobic epoxies?

Hydrophilic epoxy is an epoxy compound with many hydrophilic groups within its molecules, which means it has a high affinity for water. On the other hand, hydrophobic epoxy is an epoxy compound with many hydrophobic groups within its molecules, which means it has low affinity for water. However, even if an epoxy is hydrophilic, it is not necessarily water-soluble. Even compounds with many hydrophilic groups may not dissolve in water if they are high polymers, depending on the molecular weight or molecular structure.