- Electrification

- Global

Insert Molding for Power Modules

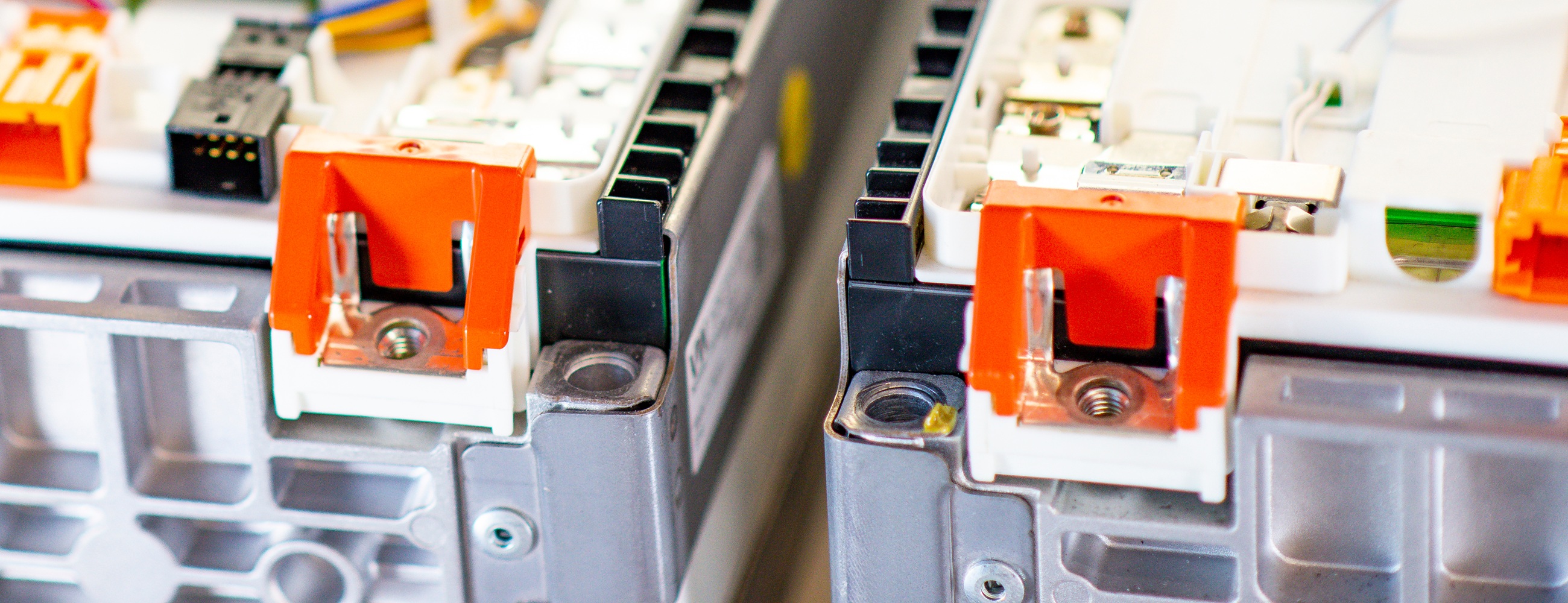

With the advances in vehicle electrification, power modules face increasingly stringent requirements for miniaturization, low inductance, and high reliability. At the same time, as the number of components and manufacturing processes increase, the risks of higher costs and greater variability in quality also rise. This article introduces insert molding technology as an effective approach to addressing these challenges. Beginning with the fundamentals of power modules, it provides a clear explanation of representative manufacturing methods and practical application examples.

What Is a Power Module?

A power module is an electronic component that integrates power semiconductor devices responsible for power conversion and control, together with wiring, insulation, thermal management, and housing functions. In recent years, driven by advances in the electrification of vehicles and the widespread adoption of renewable energy, power modules have become increasingly important as components that deliver high efficiency, high reliability, and compact design.

This section explains the main applications, functions, and key components of power modules.

Applications

Typical applications of power modules include inverters for electric vehicles (EVs) and hybrid electric vehicles, industrial motor drives, home appliances such as air conditioners and refrigerators, and power conditioners for solar and wind power generation systems.

In these fields, efficient control of high voltages and large currents is required, making reliable modularization is more essential than the use of discrete components. In particular, automotive applications demand compact and lightweight solutions that can withstand harsh temperature environments and severe vibration conditions.

Functions

Power modules are mainly used for the following:

Power conversion: Conversion between direct current and alternating current, as well as voltage and current transformation

Power control: High-speed, high-precision control of current on/off switching via switching operations

High efficiency and energy savings: Reduction of energy losses to improve overall system efficiency

Reliability: Stable operation achieved by integrating electrical connections, insulation, and thermal management

By modularizing these functions, variations in electrical characteristics can be minimized, contributing to simplified design and reduced assembly effort. Power modules can be regarded as core components that significantly influence the overall performance and reliability of the entire system.

Components

A power module has an integrated structure centered on power semiconductor devices, combining components that provide electrical interconnection, insulation, heat dissipation, and protection from the external environment.

The table below shows the typical components.

※1 IGBTs = Insulated Gate Bipolar Transistors

Power semiconductor devices that combine the high-input impedance of MOSFETs with the high-current capability of bipolar transistors. Commonly used in high-voltage, high-power applications such as EV inverters and industrial drives.

※2 MOSFETs = Metal–Oxide–Semiconductor Field-Effect Transistors

Voltage-controlled semiconductor devices known for fast switching speeds and high efficiency, widely used in low- to medium-voltage power conversion applications.

※3 SiC = Silicon Carbide

A wide-bandgap semiconductor material used to manufacture advanced power devices (e.g., SiC MOSFETs). SiC enables higher switching frequencies, higher temperature operation, lower losses, and improved efficiency compared with conventional silicon devices.

※4 DBC substrates = Direct Bonded Copper substrates

Ceramic substrates in which copper is directly bonded to a ceramic layer (typically alumina or aluminum nitride). DBC substrates provide excellent electrical insulation, high thermal conductivity, and strong mechanical bonding, making them widely used in power modules.

※5 AMB substrates = Active Metal Brazed substrates

Ceramic substrates in which copper is bonded to the ceramic using an active metal brazing process. AMB substrates offer high bonding strength, good thermal performance, and improved reliability under thermal cycling, making them suitable for high-power and high-reliability applications.

Technologies that enable the high-precision integration of these diverse components play a critical role in determining the overall performance of power modules.

Challenges of Power Modules

While power modules enable highly efficient power conversion, it is essential to simultaneously meet requirements for enhanced performance, manufacturability, and reliability.

Especially in automotive and industrial applications, it is necessary to address and balance multiple technical challenges, such as limited space and harsh operating environments.

Miniaturization and Weight Reduction

In automotive applications, installation space is limited, and larger power [JK1] modules restrict flexibility in vehicle design. In addition, increased weight negatively affects fuel efficiency and driving range. As a result, efforts are being made to:

Reduce the number of components

Increase packaging density

Adopt thinner module structures

At the same time, miniaturization must be achieved while maintaining adequate thermal performance and insulation distances, making the design process highly challenging.

Low Inductance Design

As switching speeds continue to increase, reducing wiring inductance has become a critical challenge. In particular, with next-generation power semiconductors, such as SiC devices, surge voltages and noise resulting from parasitic inductance present significant issues.

These issues can lead to device malfunction and reduced reliability, making optimization of busbars, wiring layouts, and joint structures essential. At the same time, designs are required to improve electrical performance while minimizing structural complexity and manufacturing variability.

NAGASE Mobility provides advanced solutions to help reduce inductance and enhance power modules performance. Learn more here.

Low-Inductance Solution for xEV Power Modules | NAGASE

Reduction of Manufacturing Processes

Power modules consist of many components, which often leads to many assembly, joining, and inspection processes. As a result, manufacturing effort increases, along with higher costs and risk of quality variation. When manual processes remain, ensuring productivity and repeatability becomes a challenge.

For this reason, structural designs that integrate components, consolidate processes, and reduce downstream operations are essential. Technologies are required to stabilize quality while simplifying the manufacturing process.

Thermal Management Design

In power modules, large amounts of heat are generated due to high-current and high-frequency operation. If this heat cannot be dissipated properly, elevated device temperature can lead to performance degradation and shortened lifetime. Therefore, an effective thermal management design is required to efficiently transfer heat away from the device within a limited space.

In addition to selecting appropriate cooling methods, such as air cooling or liquid cooling, it is necessary to reduce thermal resistance while minimizing unnecessary structural complexity.

Improved Reliability

Power modules are used in equipment where high reliability is a fundamental requirement, including EVs, industrial machinery, and renewable energy systems. Therefore, in addition to durability for long-term operation, consistent quality in the manufacturing process itself is a critical requirement.

As the number of components and manufacturing processes increases, variations in assembly, positioning, and joining conditions are more likely to occur, leading to performance variation and an increased risk of defects.

Insert Molding Technologies Suitable for Power Modules

The challenges faced by power modules cannot be addressed solely through improvements to individual components. The overall optimization of the structure, joining methods, and manufacturing processes is essential. One effective approach is insert molding technology, which enables resin molding and component integration to be performed simultaneously.

This section introduces insert molding technologies that are suitable for power modules.

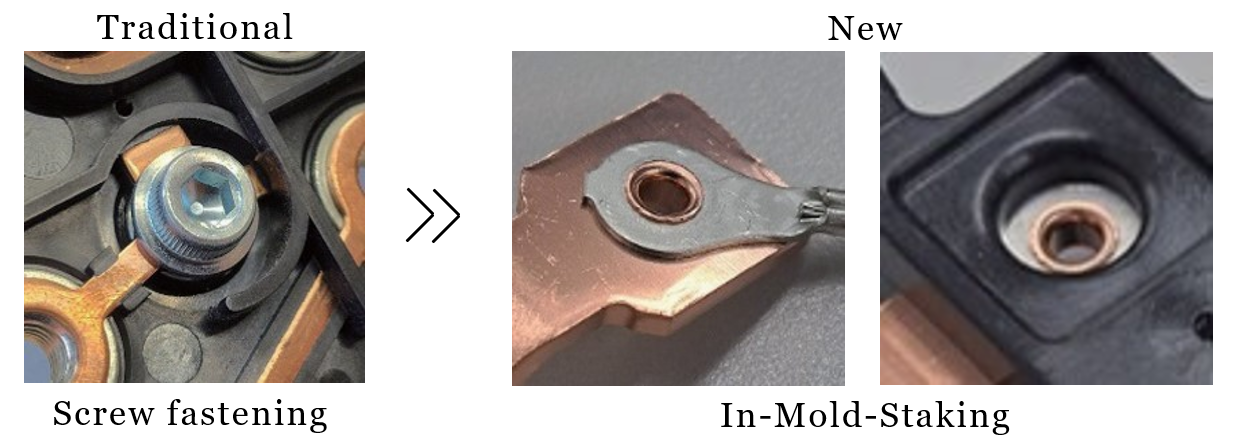

In-Mold Staking (Mechanical Caulking) Joining

In-mold staking is an insert molding technology in which metal components are placed in the mold and mechanically staked during resin molding. As components are mechanically fixed during the molding process, no additional fastening steps, such as using bolts or nuts, are required after molding. As a result, positioning and joining can be completed in a single process, allowing stable, high-quality mass production.

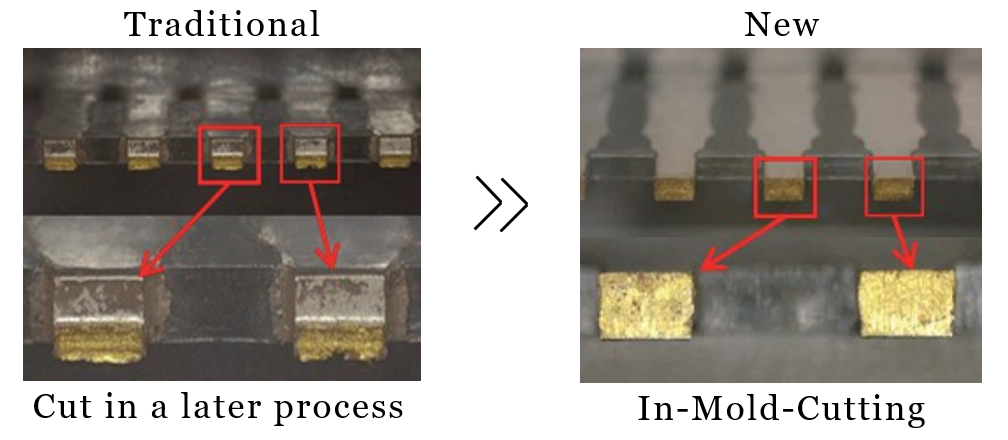

In-Mold Tie Bar Cutting

In-mold tie bar cutting is an insert molding technology in which tie bars are cut inside the mold during the molding process. By incorporating a tie bar cutting operation—normally performed as a separate post-molding process—directly into the molding process, downstream processes can be reduced. Reducing the number of processes simplifies setup and handling, helping to minimize operator-related variability and in-process defects.

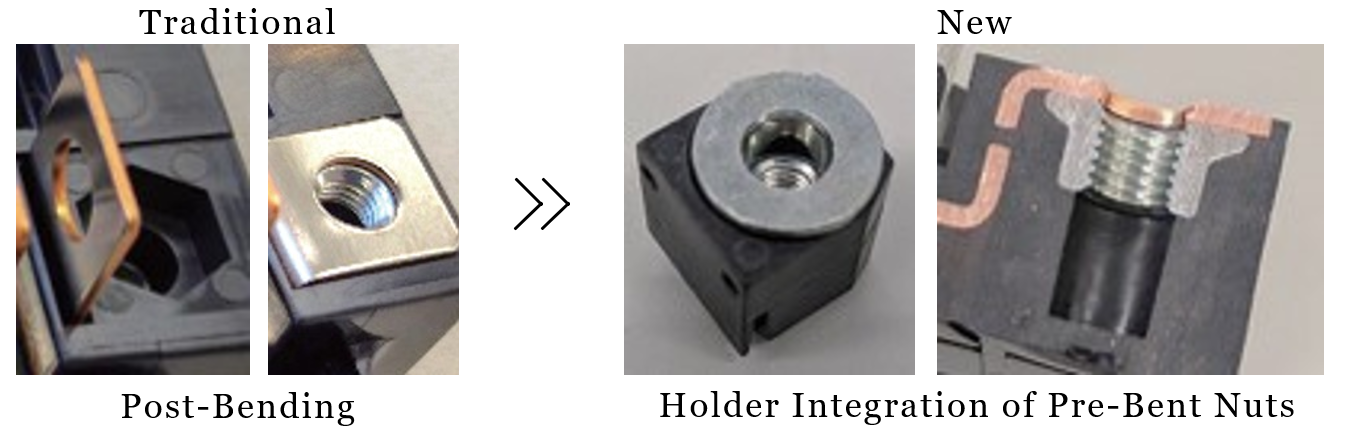

Holder Integration of Pre-Bent Nuts

Holder integration of pre-bent nuts is a technology in which metal components that hold nuts are pre-bent in advance, set in the mold, and integrated into the resin through insert molding. By eliminating the post-bending process previously required after molding, this approach helps reduce downstream operations and lowers the risk of in-process defects. In addition, it allows the use of standard through nuts instead of higher-cost cap nuts and enables the use of recycled resin by reprocessing runners generated molded parts within the factory.

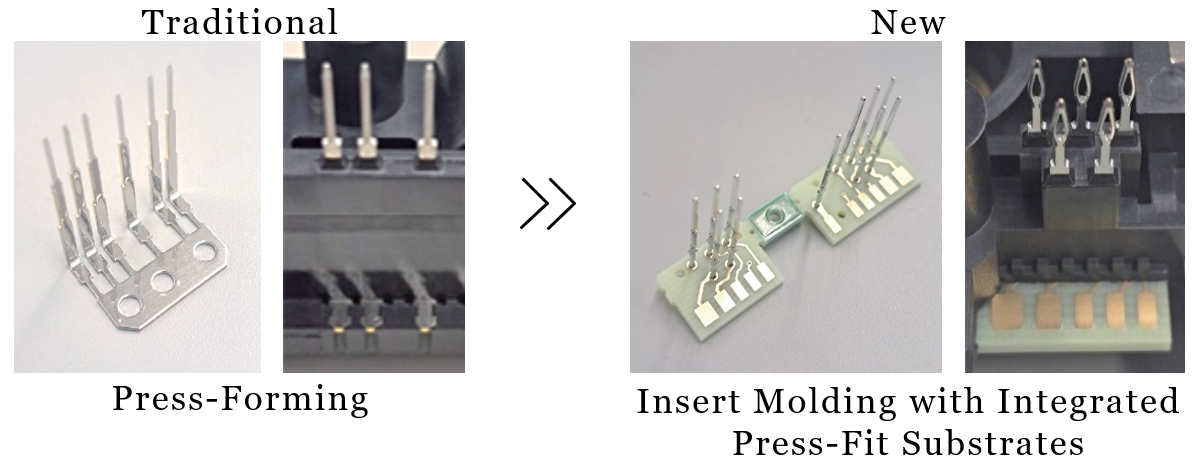

Insert Molding with Integrated Press-Fit Substrates

Press-fit integrated substrate insert molding is a technology in which a substrate and signal terminals are placed inside the mold and integrated during resin molding using a press-fit structure. This approach enables substrate mounting without the need for soldering or separate assembly processes, while ensuring stable contact quality. By integrating the molding and assembly processes, manufacturing effort can be significantly reduced.

Press-fit pins initially arranged side by side can be repositioned in a front-and-back configuration by substrate press fitting. This enables more compact customer wiring layouts and provides greater design flexibility.

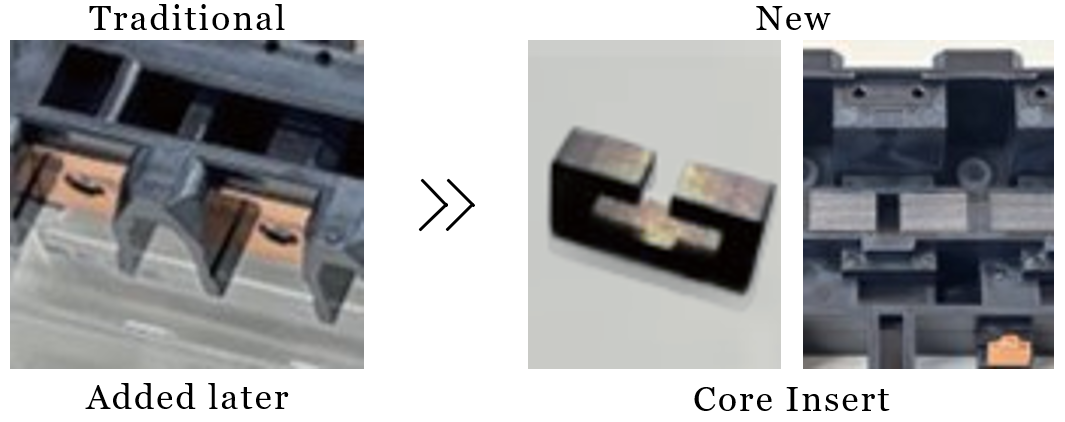

Core Insert

Core insert molding is a technology in which magnetic components, such as wound cores or laminated cores, are placed in the mold and integrated simultaneously with resin molding. Conventionally, cores had to be attached after molding, requiring additional processes and components for positioning and fixation. In contrast, in-mold integration eliminates these steps.

In addition, as the core can be molded in a pre-optimized position, unnecessary space can be eliminated, enabling a more compact overall module design.

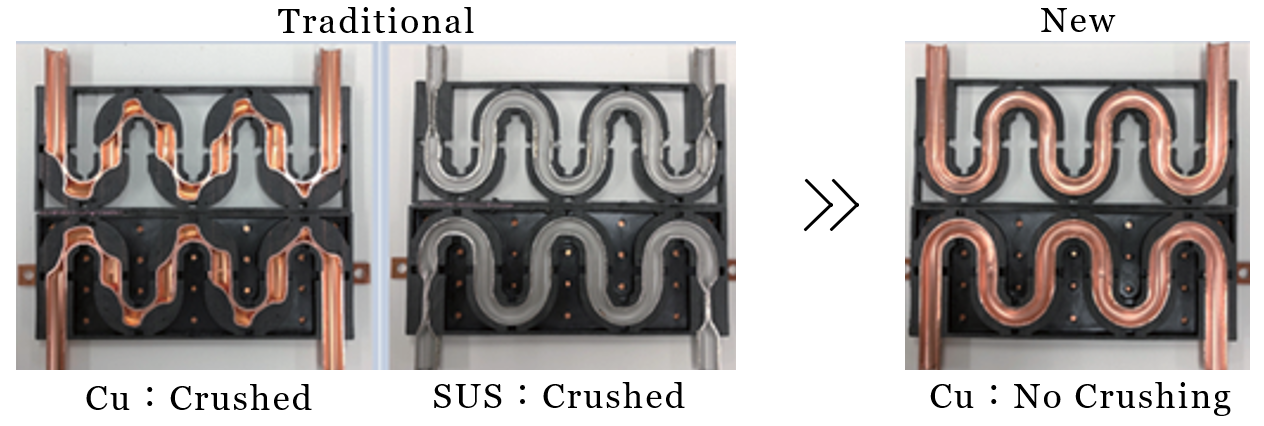

Water-Cooling Pipe Insert

Water-cooling pipe insert molding is a technology in which cooling pipes are placed inside the mold and integrated during resin molding. This approach reduces costs associated with the post-installation of heat sinks and cooling pipes, while improving adhesion between cooling components and the resin parts, enabling more efficient heat transfer.

Large-Scale Staking Joining

Large-scale staking joining integrates the press-based staking of thick metal components or large parts with insert molding. Conventionally, thick components required separate pressing or fastening processes. As a result, by performing staking joining within the molding process, these processes can be consolidated.

In addition, the formation of reliable surface contact allows contact resistance to be maintained at a low and stable level, enabling highly reliable electrical connections in high-current regions.

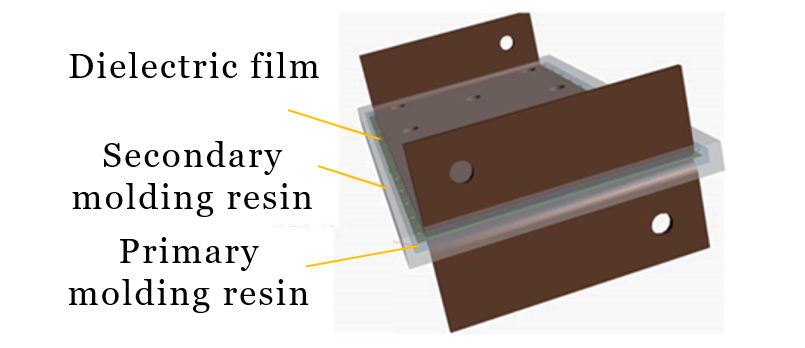

Low-Inductance Busbar Insert Molding

Low-inductance busbar insert molding integrates ultra-thin busbars with insulating materials in a single insert molding process. By optimizing spacing and arrangement between busbars during molding, the required insulation performance can be ensured while maintaining a thin, compact structure.

NAGASE Mobility provides advanced solutions to help reduce inductance and enhance power modules performance. Learn more here.

Low-Inductance Solution for xEV Power Modules | NAGASE

Examples of Insert Molding Technology Applied to Power Modules

This section presents two examples demonstrating how the application of insert molding in power modules improves manufacturing efficiency and electrical performance.

Achieving Process Efficiency and High Performance Through In-Mold Staking

The first example focuses on improving manufacturing process efficiency.

As EV-related components move toward higher current and higher voltage operation, there is a growing need for technologies that can reliably join sensor terminals and copper busbars with high electrical conductivity. However, conventional approaches, such as additional plating or resistance welding, increase the number of manufacturing processes and tend to result in point contacts, raising concerns about variability in electrical conductivity.

To address this issue, in-mold staking joining—one of the insert molding technologies—was adopted. By stacking the terminals and busbars in surface contact within the mold and integrating them during molding process, the compressive forces during molding further enhanced contact intimacy.

[Conceptual diagram of busbar and terminal crimping within the die]

As a result, electrical conductivity was stabilized, and both the component's mechanical robustness and electrical performance improved. In addition, because no extra processing steps were required, the design achieved cost advantages through reduced manufacturing processes.

Achieving Low Inductance through Integrated Molding of Busbars and Insulating Films

The second example focuses on achieving low inductance.

As advancements in power semiconductor performance continue to reduce switching losses, suppressing inductance-related losses caused by current fluctuations have become the next key area for improvement.

To address this challenge, an insert molding technology—integrated molding of busbars and insulating films (low-inductance busbar insert)—was applied. By bringing the positive and negative busbars closer together while maintaining insulation, busbar spacing on the order of 0.1 mm was achieved—a level that had been difficult to realize with conventional resin filling methods.

[Achieving ultra-low inductance through integrated molding of busbars and insulation film]

By providing a resin frame around the insulating film to prevent misalignment and damage, losses were reduced without compromising reliability, enabling a design that contributes to improved energy efficiency.

NAGASE Insert Molding Solutions for Power Modules

Insert molding technology is an effective solution to the challenges faced by power modules, including miniaturization, low inductance, manufacturing process reduction, thermal performance, and reliability.

The NAGASE Group provides end-to-end solutions—from technology development to mass production—by offering not only insert molding technologies, such as in-mold staking and low-inductance busbars, but also optimized resin material selection tailored to specific applications and performance requirements, the evaluation of manufacturing methods suitable for mass production, and the establishment of supply chains that support a stable supply.

For inquiries regarding insert molding technologies for power modules—from initial concept discussions to mass production support—please feel free to contact NAGASE.