- Electrification

- Global

The Present and Future of Electric Powertrains: Insights from Professor Masayoshi Yamamoto of Nagoya University

Developments in electric vehicle (EV) powertrains demand as much attention as battery technology. We speak with Professor Masayoshi Yamamoto of Nagoya University's Institute of Materials and Systems for Sustainability, a leading authority in power electronics. He shares his views on critical trends within the electric powertrain sector, covering power module cases, substrate mounting, current sensors, and insulating materials.

Advanced Cooling: Integrated Heat Exchanger for High Heat Dissipation in Power Modules

“Efficiently managing the heat generated by increased voltage is a critical factor in the design of modern automotive power modules.”— Professor Yamamoto

The electric powertrain, alongside the battery, is the key area for technological development in EVs. NAGASE is collaborating with partners to develop the crucial power module case, recognizing the inverter's pivotal role.

"One component manufacturer incorporated an integrated microchannel heatsink structure inside the power module case for cooling. I believe this contributes significantly to the overall low-profile design of the inverter, making it a masterpiece of thermal packaging."

The integrated cooling structure's high heat dissipation prevents the inverter’s operating temperature from becoming excessively high, even as voltages increase. This innovation enabled the manufacturer to use more affordable aluminum for the cooling base, instead of expensive, highly conductive materials like nickel-coated copper.

SiC Power Semiconductors: Trends in Operating Temperature and Sintering Methods

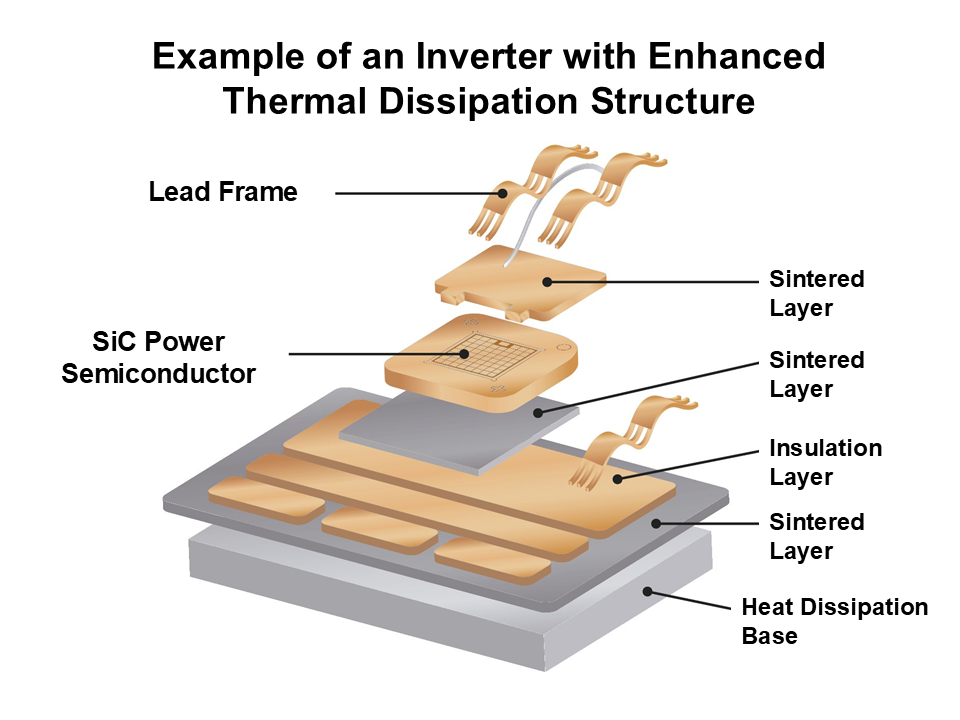

The push for higher power density and performance requires innovation not just in the cooling base, but also in the chip-to-substrate interfaces.

Beyond cooling substrate material, trends are shifting in materials used for bonding chips during substrate mounting.

As EV performance advances, power consumption increases:

Power semiconductors are migrating from conventional Silicon (Si) to Silicon Carbide (SiC), which leads to higher operating temperatures.

To counter this, the trend is moving away from traditional solder to sintered silver or sintered copper, which have higher melting points.

"For instance, some automaker’s inverters array as many as 24 SiC chips. This high-density arrangement causes highly localized heat distribution (hot spots). Since this unevenness negatively affects cooling efficiency, manufacturers are implementing precise manufacturing measures, such as uniformizing the thickness of the sintered material beneath the chips. Automotive power electronics is a constant battle against thermal stress."

48V Power Systems for Electrification Beyond the Drivetrain

The rising complexity of vehicle systems requires higher-voltage architectures beyond the primary EV traction system.

This design anticipates scenarios where high voltages exceeding 48V are generated. Professor Yamamoto explains that as the number of auxiliary components becomes electrified across the vehicle, adopting a 48V mild hybrid power system becomes necessary.

"The wave of electrification is reaching components traditionally found in internal combustion engine vehicles... For example, to instantly achieve peak efficiency in a Mild Hybrid Electric Vehicle (MHEV), the demand for actively controllable electric superchargers or turbos increases. As the proportion of previously non-electric components becomes electrified, there is no choice but to adopt a 48V power system to deliver the required auxiliary power."

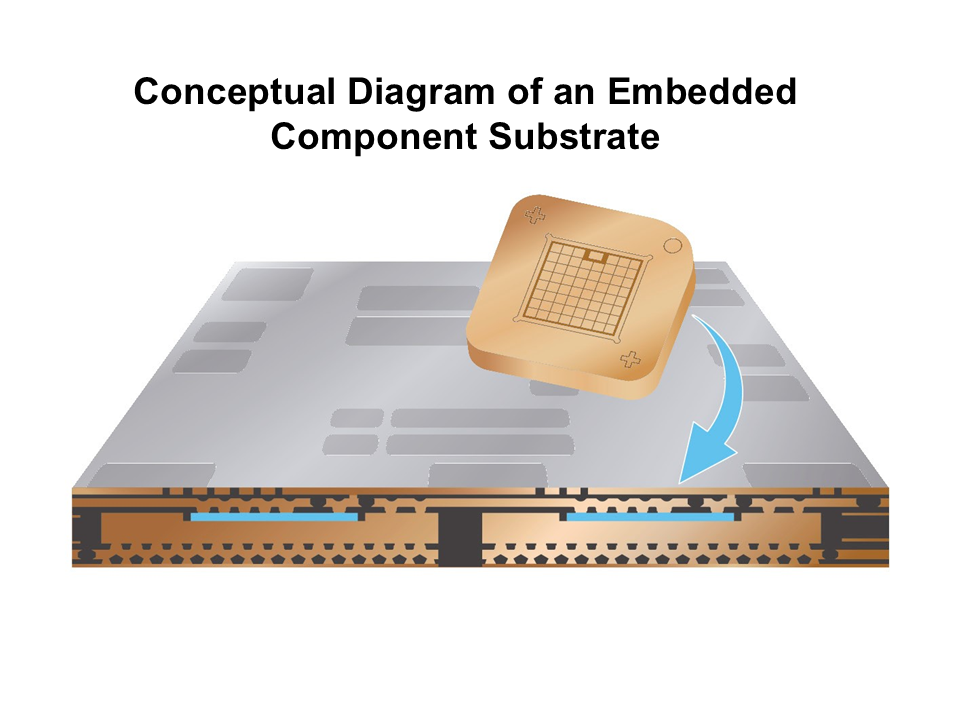

These collective trends—low-profile design, low inductance, and enhanced heat dissipation—are driving increased market attention toward component-embedded substrate technology.

Current Sensor Methods Evolve with Requirement Differences

Current sensors are essential for real-time motor control and protection. Professor Yamamoto identifies three main trends, noting that the required precision and method will change depending on the 'degree of electrification’:

Magnetic Core Method (e.g., Fluxgate/Closed-Loop Hall):

Strength: High Precision (Crucial for high-performance BEVs detecting large currents over a wider range).

Drawback: Tends to be larger in size.

Coreless Method (e.g., Open-Loop Hall/MR):

Goal: Addresses the strong market demand for miniaturization.

Mechanism: Uses magnetic sensors (e.g., Hall elements).

Note: Generally offers less precision than the magnetic core method but contributes to smaller component size. May be acceptable when electric components are used merely for 'engine support.'

Shunt Resistor Method:

Features: Detects current flow through a shunt resistor. Principle is relatively simple and has an extensive track record.

Drawback: Generates measurable heat, requiring thermal countermeasures.

He states that in hybrid EVs and BEVs, the required precision and method will change depending on the 'degree of electrification.' Simultaneously, he stresses the vital importance of redundancy.

"Scenes where the engine is eliminated and the vehicle runs purely on electricity (BEVs) will increase. The overall system must be designed to allow for safe standalone operation—enough to exit the highway—even if a component fails. This is what we mean by redundancy, and it is an extremely high-value element for functional safety. Some hold the view that redundancy necessitates paralleling two inverters. In that scenario, the selection of the current sensor method and the conditions to ensure redundancy must be determined while considering various operational situations."

Insulating Materials See Increased Demand with Motor Speed

Motors are becoming more powerful and compact, placing new demands on material science.

NAGASE is promoting specialized insulating materials designed for motor applications.

"To achieve high output, motors must rotate at high speeds. While this offers the advantage of miniaturization, it puts a significant load on the speed reducer (gearbox) and generates substantial heat. When the gears heat up, cooling is required, leading to increased adoption of ATF (Automatic Transmission Fluid) cooling as a countermeasure. Consequently, the need for specialized insulating materials with high chemical resistance and ATF resistance will undoubtedly grow."

Conclusion

The electric powertrain, whose performance is enhanced by the complex interplay of various factors, will remain a compelling area to watch. Significant challenges, such as implementing effective countermeasures for the operating temperature of power semiconductors, exist. NAGASE supports the future of EVs and addresses these industry challenges with its products and technologies.

Pleaese also read the following articles, intdroducing solutions for xEV:

・Creating "Art" in xEV Manufacturing with Insert Molding: Part 1 of 2 - The ATECS Approach | NAGASE Mobility | NAGASE

・Creating "Art" in xEV Manufacturing with Insert Molding: Part 2 of 2 - ATECS' Advanced Automation & Global Expansion | NAGASE Mobility | NAGASE

・Contributing to Compact, High-Output, and High-Efficiency xEV Motors with “Namli®” — a Motor Insulation Material with Exceptional Environmental Resistance | NAGASE Mobility | NAGASE