- Environment

- Global

"3mesh" Material for Seat Ventilation Contributes to Energy Efficiency by Enhancing the Breathability of Car Seats

While enhancing energy efficiency is crucial when operating electric vehicles, reducing the energy consumption of the air conditioning system is also a significant factor. To address this challenge, we have partnered with the German company, Muller Textiles GmbH, to deliver the recyclable "3mesh" mesh material, which contributes to a well-ventilated car seat design. By delivering innovative products in user-friendly shapes, we contribute to improving energy efficiency in electric vehicles.

The Issue

Issue: Development of New Materials for Ventilation Systems Targeted at Enhancing Energy Efficiency

Amidst the growing global awareness of the environment, the automotive industry is promoting a shift from gasoline cars to electric vehicles as a measure to reduce greenhouse gas emissions. As electric vehicle development accelerates worldwide in response to this trend, improving the driving range is one of the most notable aspects of electric vehicle performance. Designing cars that efficiently utilize energy to enable electric vehicles to travel as far as possible on a single charge is crucial, necessitating evolution in automotive components from every angle.

Car seats are no exception to this trend. Since seats are components that come into contact with the human body, various approaches have been devised, especially during hot seasons, to reduce energy consumption from air conditioning. For example, materials with good breathability are being adopted for seats, and developments like built-in fans, or ventilation systems, in the seats that circulate air to cool both the seat and the backrest are being pursued. These developments aim to save energy and ensure comfort by minimizing the perception of heat on the body.

Furthermore, conventional polyurethane used in seat components often poses challenges for recycling, which in many cases leads to disposal becoming unavoidable.

Given such requirements, it can be said that future electric vehicle seats should ideally be designed with good breathability to ensure comfort while operating energy efficiently. Additionally, designs that enhance recyclability of the product would be desirable.

The Solution

Approach: Exploring Materials for Ventilation Seats in Collaboration with Muller Textiles GmbH

At NAGASE, we are collaborating with Muller Textiles GmbH, headquartered in Germany, to advance the development of breathable materials primarily composed of polyester, as we envision an increase in the adoption of seats equipped with a ventilation system (ventilation seats) in the future.

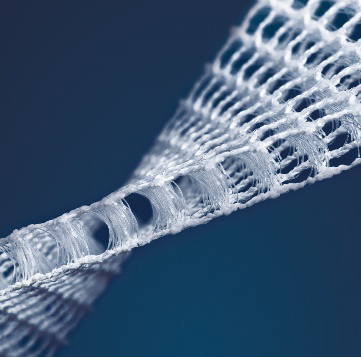

Muller Textiles' "3mesh" is a knitted (mesh-type) material made from polyester fibers, designed to be used in areas of seat products where conventional urethane is typically utilized. Being a mesh-type material, it can efficiently transmit the airflow generated by fans installed within the ventilation seats to the human body, contributing to the design of well-ventilated seats.

Furthermore, unlike urethane, which is said to have high recycling difficulty, "3mesh" due to its main component being polyester, can contribute to enhancing the recyclability of seat products. With such characteristics, "3mesh" is increasingly being adopted by leading car seat manufacturers in Europe, North America, and Asia as a material for advanced car seats.

At NAGASE, we have established a system to cut and supply "3mesh" into specified shapes, produced in Europe, China, or North America according to our customers' needs. Additionally, by partnering with related companies, we have developed a process to offer "3mesh" integrated with the upholstery as a unified shape.

In the increasingly spotlighted electric vehicle sector, NAGASE will continue to collaborate with partner companies to advance development towards improving the performance of electric vehicles and achieving a society with low environmental impact, focusing on enhancing energy efficiency.