- Environment

- Global

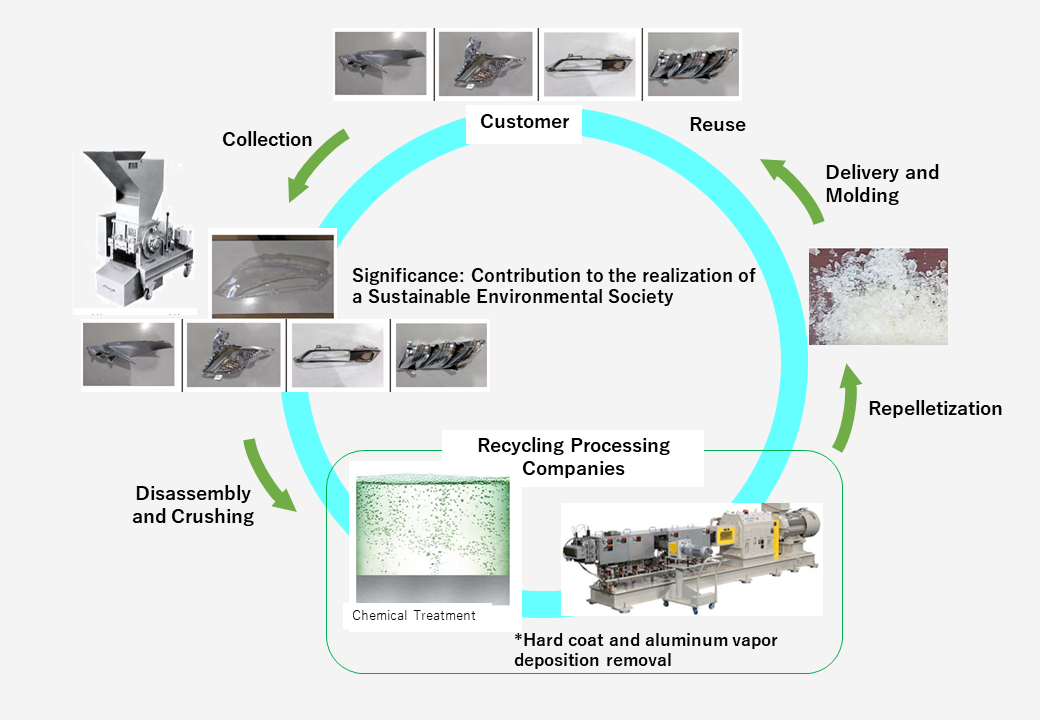

Striving to Build a Circular Economy through the Recycling of Scrap Materials in the Automotive Lamp Component Manufacturing Process

In the manufacturing process of automotive lamp components, defective products and scrap materials are often collected and disposed of, contributing to environmental concerns. NAGASE, in collaboration with our partners, has established advanced plastic material recycling technology. By reintroducing these materials into our products, we achieve the 3Rs (Reduce, Reuse, Recycle) and aim to contribute to environmental sustainability.

The Issue

Advancing Circular Economy Practices for Automotive Lamp Parts

Among the various types of waste, plastic waste is particularly noted for its association with numerous environmental pollution problems. This is primarily because plastic is resistant to natural decomposition. Unlike organic waste, which breaks down relatively quickly, plastic can persist in the environment for decades to centuries, raising concerns about long-term impacts.

When plastic waste is incinerated, it emits CO2, a greenhouse gas that contributes to global warming. With an increase in plastic waste incineration, CO2 emissions also rise, further accelerating the progression of global warming.

Additionally, illegally dumped plastic waste flows into rivers and oceans, causing marine pollution that harms marine life and humans who consume seafood. This pollution deteriorates water quality, negatively impacting the fishing industry and overall living conditions. Reports indicate that since 1950, over 70% of the 8.3 billion tons of global plastic production have become waste, with about 80% ending up in landfills or the ocean. By 2050, the amount of plastic waste in the ocean may exceed the quantity of fish, highlighting the severity of the issue.

In light of this, the issue of plastic waste emerges as a critical environmental dilemma, demanding immediate action to prevent further damage to the environment.

Establishing a circular economy for automotive lamp parts presents a significant hurdle for both NAGASE, a seasoned handler of plastic products, and its automotive lamp manufacturer customers, who emit substantial plastic waste during their production process.

The Solution

Challenge to Develop a Program for Producing Recycled Plastic Using Process Waste

At NAGASE, we are dedicated to building a network that connects our customers with partner companies equipped with recycling technology, all in pursuit of achieving a circular economy for plastic products.

Drawing on our extensive experience in selling plastic products (virgin materials) and the collective knowledge within our company, we actively collect end-of-life lamp components primarily made from plastic generated during our customers' processes. These components, having reached the end of their production cycles, are gathered, and we initiate discussions with partner companies and logistics providers to establish recycling schemes. These schemes involve processes like grinding the collected waste plastics, chemical cleaning to remove adhered aluminum, and pelletizing the cleaned scraps, with the ultimate goal of transforming the collected waste plastics into reusable materials.

Additionally, it is essential for NAGASE to verify the feasibility of using repelletized recycled plastics as automotive lamp components.

Within the NAGASE Group, we have facilities and specialized technical staff, such as the NAGASE Application Workshop, capable of conducting plastic evaluation analysis, application development, and final product formulation development. Furthermore, our organization possesses functions for technical development, incubation, and training.

By leveraging the capabilities of the NAGASE Application Workshop, we are conducting trials with the goal of returning verified recycled plastics to our customers for reuse in automotive lamp manufacturing.

Drawing on our extensive knowledge of automotive components accumulated over the years and the trust placed in us by our customers, NAGASE remains committed to contributing to the realization of a circular economy in the mobility industry.