- Electrification

- India

The Future of High-Capacity EV Batteries: Silicon-Based Anodes

A persistent challenge for electric vehicle (EV) batteries is their driving range on a single charge. While advancements in lithium-ion battery (LiB) research have enabled some EVs to rival the range of internal combustion engine (ICE) vehicles, a significant gap in energy efficiency remains. A conventional LiB has an energy density of roughly 250 Wh/kg, whereas gasoline offers 3,000–4,000 Wh/kg—a more than tenfold difference, even accounting for thermal efficiency. To achieve performance similar to an ICE vehicle, an EV must carry a large number of batteries, which significantly increases the vehicle's weight and cost. This article will focus on silicon-based anode materials for batteries, which NAGASE Mobility is developing with a partner company as a solution to this problem.

The Issue

Boosting Battery Energy Density

A key way to improve a battery electric vehicle's (BEV) driving range is by increasing the energy density of its lithium-ion battery (LiB). The anode material plays a crucial role in LiBs by storing lithium ions during charging and releasing them during discharging.

The current standard anode material is graphite, which has a capacity of about 360 mAh/g and a relatively low expansion rate of about 130%. On the other hand,silicon (Si) offers a much higher capacity of approximately 4,200 mAh/g, which is more than ten times that of graphite.

However, a major challenge with silicon is its high expansion rate. When used as an anode, its volume can expand by as much as 300% during charging and contract during discharging. This repeated expansion and contraction can cause the anode material to break down and peel away, leading to a significant loss of battery capacity over time.

Therefore, using pure silicon as an anode is not a viable solution. To mitigate this issue and make silicon-based anodes practical, manufacturers use silicon in a modified form. This commonly involves:

Combining silicon with an oxide to create a silicon oxide (SiOx) type.

Mixing silicon with porous carbon to form a silicon-carbon (SiC) type.

These composite materials effectively reduce expansion and contraction, making them suitable for long-term use. While the capacity of the SiOx type (around 1,400 mAh/g) is lower than that of pure silicon, it's still more than four times higher than graphite. To achieve further capacity gains, silicon-based materials are typically blended with graphite.

The Solution

A New Generation of Silicon-Based Anodes

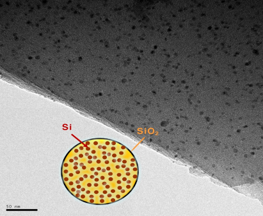

To address the challenges of high-capacity EV batteries, NAGASE Mobility has partnered with a leading provider of silicon anode materials. This partner specializes in a unique metal-doped silicon oxide (SiOx) material that delivers high capacity and high initial efficiency while being suitable for mass production.

This new generation of silicon-based anodes features:

A unique structure with uniformly dispersed Si nanocrystals within an SiOx matrix. The partner's technology excels at uniformly dispersing nano-sized Si particles within the SiOx matrix, creating a three-dimensional structure.

Precise control over particle size and spacing. Controlling the size of the Si nanoparticles and the distance between them enables the development of new products with high capacity, high initial efficiency, and excellent cycle stability.

Competitive advantage in manufacturing. The unique synthesis process of the particles gives the partner a competitive edge in both mass production and cost. In fact, this material was the first silicon-based material to be mass-adopted for BEVs in the European market and continues to gain mass production experience.

NAGASE Mobility's Collaborative Approach

NAGASE Mobility not only promotes this unique material but also works to facilitate its practical application. A key challenge is addressing the high expansion rate of silicon-based materials, which can increase the risk of active material peeling off. To mitigate this issue, we provide recommendations for specialized binders that enhance the cycle life of silicon anodes.

For more information on our silicon-based binder solutions or other advanced battery material solutions, please contact NAGASE Mobility.