- Electrification

- Global

Creating "Art" in xEV Manufacturing with Insert Molding: Part 2 of 2 - ATECS' Advanced Automation & Global Expansion

As the global electric vehicle (xEV) market surges, manufacturers face growing pressure to deliver high-performance components at scale without compromising quality. In Part 1, we explored how ATECS’ advanced insert molding technology meets the complex demands of power module cases. In the Part 2, we highlight how ATECS is scaling its impact—through full automation of its production line and global expansion efforts, including the launch of AIM (ATECS Insert Molding Mexico S.A. de C.V.), a joint venture with NAGASE in Mexico designed to serve the North American xEV market.

The Issue

Balancing Quality, Volume, and Speed

You can read Part 1 here.

Historically, power module case production has relied on multiple manual steps—metal terminal handling, insert molding, post-processing, and inspections. While this manual approach delivered reliable results, it introduced serious inefficiencies:

・Labor-intensive operations

・Inconsistent cycle times

・Risk of human error

・Limited scalability for overseas demand

Compounding the issue is the evolving landscape of xEV supply chains. With rapid growth in regions like China and North America, proximity to customers is no longer optional—it’s essential. Without advanced automation and a global footprint, ATECS would struggle to meet the evolving expectations of automakers and Tier 1 suppliers.

The Solution

ATECS’ Solution: Automation-Driven Efficiency and Strategic Expansion

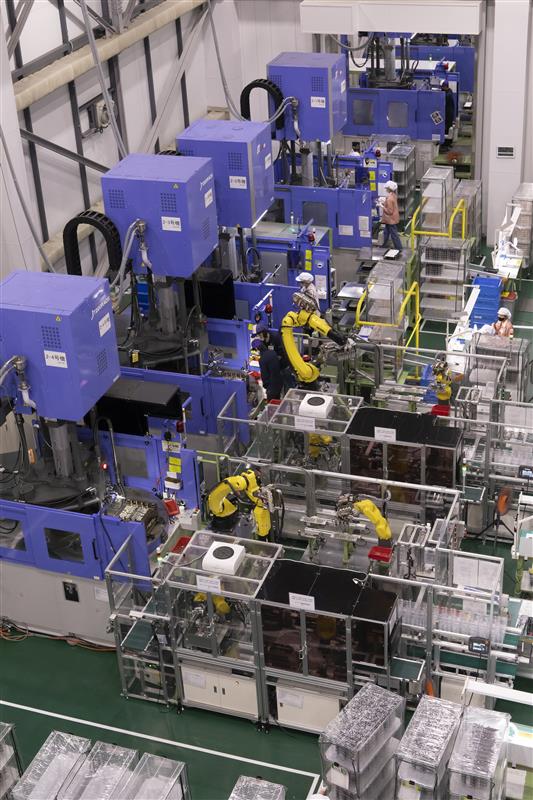

1. Fully Automated Production Line

ATECS has implemented a completely automated workflow—from in-house metal pressing to final visual inspection. This overhaul eliminates manual handling and optimizes every phase of the insert molding process:

Integrated metal pressing eliminates third-party handling and improves precision.

Robotic automation handles terminal positioning and molding with unmatched consistency.

Automated trimming and burr removal reduce downtime and waste.

Automated quality inspections detect micro-defects in real time, ensuring zero-compromise standards.

The result: faster production cycles, greater consistency, and higher output, especially important in volume-intensive markets like North America.

2. Strategic Global Expansion

To support regional supply chains and reduce lead times, ATECS is expanding its manufacturing footprint:

2017, Expanding to China: ATECS and NAGASE co-founded Huizhou Sanli Three Precision Co., Ltd. in Guangdong Province. This facility supports local EV manufacturers with insert molding components built to Japanese quality standards.

2024, Expanding to Mexico: In North America, ATECS and NAGASE have launched a new joint venture: AIM, based in León, Mexico. This site is designed to:

Serve North American OEMs and Tier 1 suppliers

Support local procurement and manufacturing

Simplify logistics and reduce supply chain complexity

By replicating its proven processes abroad, ATECS ensures that global customers benefit from the same quality, reliability, and innovation that define its Japan-based operations.

Partner with ATECS for Scalable, High-Quality xEV Solutions

ATECS, in partnership with NAGASE, is redefining insert molding for the electric mobility era. With end-to-end automation and a growing global presence, we’re ready to support the next generation of power module development—anywhere in the world.

Interested in scalable, high-performance insert molding solutions for your xEV project?

Let’s discuss how ATECS and NAGASE can bring unmatched precision and productivity to your supply chain.

Contact us today to learn more.