- Electrification

- Global

Creating "Art" in xEV Manufacturing with Insert Molding: Part 1 of 2 - The ATECS Approach

The electric powertrain in electric vehicles (EVs) is the core system responsible for driving the vehicle. Among its key components, power modules based on power semiconductors have seen remarkable advancements. Today, we introduce ATECS Co., Ltd. (hereinafter referred to as "ATECS"), headquartered in Higashi-Osaka, with manufacturing sites in Japan and China, and a new facility scheduled to start production in Mexico later this year. ATECS is a partner of NAGASE specializing in power module cases—critical for efficiently transmitting the power converted by power modules.

The Issue

The Shift Towards High-Current, High-Voltage Components

As the adoption of xEVs—including BEVs, HEVs, and PHEVs—continues to accelerate, the demand for higher current and voltage in electrified components is rapidly growing. Driving this trend is the advancement of power electronics, with power modules emerging as a key focus area within the industry.

Inside power modules, power semiconductors such as silicon (Si) chips are embedded. The increasing need for miniaturization and lightweight designs in electrified components has driven continuous advancements in power semiconductor technology. Recently, to meet the growing demands for high-current and high-voltage applications, SiC (Silicon Carbide) power semiconductors are replacing traditional Si-based semiconductors in power modules.

What Is a Power Module?

Power modules consist of multiple key components, including:

Power semiconductors that switch and regulate electricity.

Insulated substrates made of high-thermal-conductivity materials such as copper or ceramics, which dissipate heat.

Encapsulation materials such as silicone or epoxy resin that provide insulation and protection.

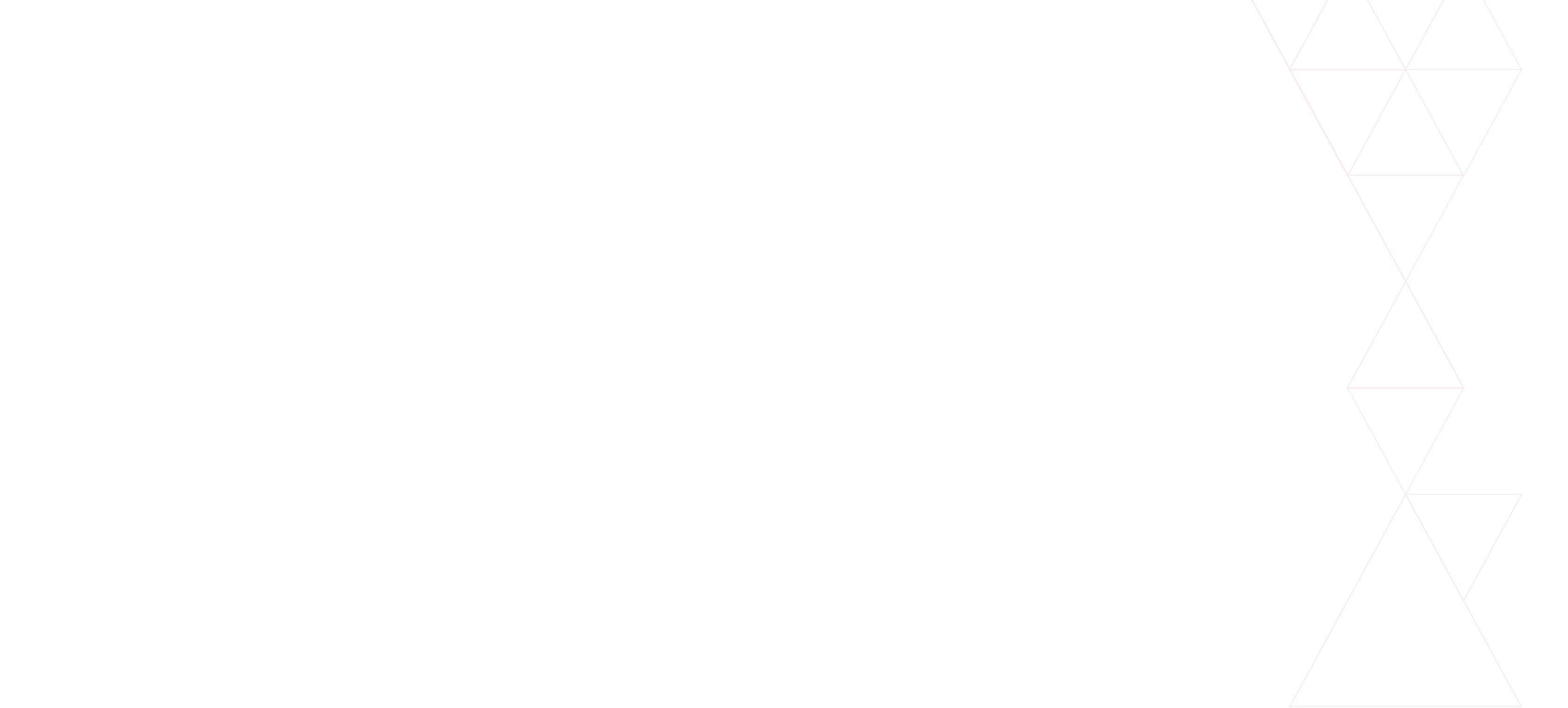

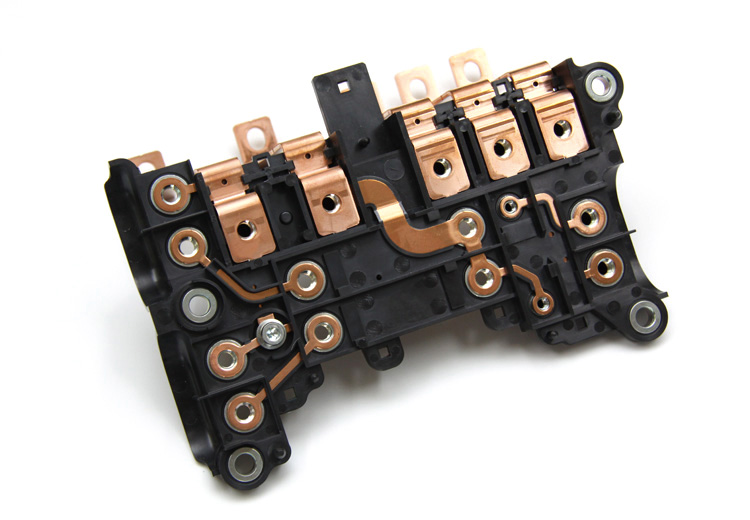

The insulated substrate plays a crucial role in dissipating the heat generated by power semiconductors efficiently. Additionally, power modules must be protected from external environmental factors while ensuring stable electrical connections with external circuits. To achieve this, power module cases—complex structures combining conductive metal terminals (copper) and insulating resin—are used.

Complex Power Module Cases: Adapting to High Current and High Voltage

As power semiconductors operate at ever-increasing current and voltage levels, power module cases must efficiently dissipate heat, protect components from environmental factors, and ensure electrical insulation between multiple power semiconductors and external circuits.

Simultaneously, miniaturization, weight reduction, and low-profile designs are also required, adding to the complexity of power module case structures.

The Solution

ATECS’ Approach: Creating "Art” with Insert Molding

To produce these highly sophisticated designs, the combination of metal terminals and insulating resin must be precisely molded into intricate shapes. Achieving this requires:

Advanced design capabilities to create optimal geometries.

Streamlined manufacturing processes to ensure high efficiency and precision.

This is where ATECS’ unique insert molding technology comes into play.

As a development-focused partner of NAGASE, ATECS excels at highly intricate and technically demanding molding processes.

The company specializes in composite insert molding, where metal and resin are molded together in a single step to form power module cases, battery disconnect units (BDUs), and terminal blocks—all essential xEV components requiring sophisticated design.

ATECS’ strengths include:

Translating customer concepts into detailed design drawings.

Proposing design optimizations for customer blueprints.

Contributing to the miniaturization, weight reduction, and low-profile development of xEV components.

Their expertise ensures that even the most complex designs can be efficiently manufactured using high-precision insert molding.

If you are facing similar challenges, reach out via our form—our specialists are ready to assist.

Looking Ahead to Part 2

In the next section, we will explore ATECS’ advanced automation systems, which maximize productivity and quality. We’ll also dive into their global expansion efforts, including new production facilities in China and Mexico.

Stay tuned for more insights into how ATECS and NAGASE are revolutionizing xEV power module manufacturing!