- Electrification

- Global

Three Ways to Protect Vehicle from LiB Thermal Runaway: Part 2 of 2

Improving the safety of Lithium-ion Batteries (LiBs) in Electric Vehicles (EVs) has become a top development priority. To prevent ignition from thermal runaway and suppress fire spread, NAGASE Moblity is collaborating with a Chinese partner company (partially funded by NAGASE Mobility) to offer advanced safety solutions. This is the second installment of our series. While Part 1 focused on fireproofing solutions, this article introduces insulation and humidity control materials as essential, complementary measures to enhance overall battery pack protection.

The Issue

For an overview of fireproofing solutions, please refer to Part 1.

The Core Safety Challenges

Thermal runaway is a catastrophic event where an overheated battery cell ignites and transfers heat to surrounding cells, potentially leading to the failure of the entire battery pack.

An often-overlooked risk is moisture buildup. Within the sealed battery pack, condensation can form, leading to short circuits and further safety hazards. Addressing these threats requires solutions that effectively manage both heat transfer and humidity levels.

The Solution

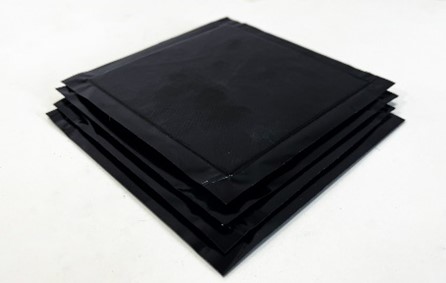

Inter-Cell Insulation: Stopping Cascading Thermal Runaway

To prevent heat transfer between cells and stop the spread of thermal runaway, we introduce Inter-Cell Insulation Material.

Key Features:

Thermal Barrier: Designed to be placed between battery cells to physically prevent heat transmission.

Superior Insulation: It is a lightweight, advanced inorganic fiber nanocomposite that is highly effective at heat insulation, maintaining battery pack integrity.

Extreme Heat Resistance: Exhibits low thermal conductivity at high temperatures. Test results show it can withstand a 1,000°C flame for over 10 minutes.

Long-Term Durability: The durability of the inorganic nanofibers ensures sustained reliability in EVs.

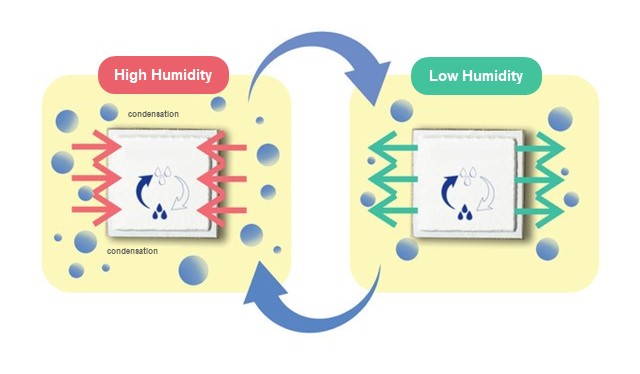

Humidity Control: Preventing Condensation-Induced Short Circuits

To regulate internal humidity and prevent short circuits caused by condensation, we offer Moisture (Humidity) Control Material.

How This Material Works:

Composition: Made by impregnating polyester fibers with high-molecular-weight, water-absorbing polymers.

High Absorption: It can absorb up to twice its weight in water, with an absorption rate of 50–70%.

Semi-Permanent Cycle: It releases absorbed moisture when humidity drops, allowing for repeated absorption cycles and ensuring semi-permanent use.

Proven Technology: Initially developed for anti-fogging in automotive cameras, this technology is now highly effective in battery packs, especially in environments with high humidity or temperature fluctuations.

Comprehensive Safety Measures for LiBs

NAGASE Mobility, alongside our Chinese partner company, is proactively developing solutions to prevent LiB thermal runaway. By integrating fireproofing (Part 1), insulation material, and humidity control material, we implement a multi-layered approach to battery safety.

Elevate Your EV Safety Standards Today

Ready to integrate the next level of thermal and moisture protection? Contact NAGASE Mobility’s LiB safety experts today to discuss your specific requirements and explore how our comprehensive material portfolio can enhance your product’s safety and longevity.