- Electrification

- Global

Contributing to Compact, High-Output, and High-Efficiency xEV Motors with “Namli®” — a Motor Insulation Material with Exceptional Environmental Resistance

To achieve compact, high-output, and high-efficiency electric vehicle (xEV) motors, the market is responding with higher currents, higher voltages, and faster rotational speeds. As motor speeds increase, heat generated by iron loss at high RPMs becomes a critical issue that necessitates effective cooling methods. One promising solution is oil cooling using Automatic Transmission Fluid (ATF), which has gained industry attention. However, there is a concern that adhesives used in motor insulation may degrade when exposed to ATF. In response to this challenge, NAGASE Mobility, in collaboration with Kawamura Sangyo Co., Ltd., introduces “Namli®,” an adhesive-free insulation material designed to help future-proof xEV motors.

The Issue

To realize compact, high-power, and high-efficiency xEV motors, the market is addressing the need for increased current, higher voltage, and higher rotational speeds.

As motors operate at higher speeds, the resulting increase in iron loss leads to heat generation, necessitating effective cooling methods. ATF oil cooling has garnered attention for its effectiveness. However, a challenge arises as adhesives used in motor components can deteriorate when exposed to ATF.

In collaboration with Kawamura Sangyo, we introduce an initiative supporting the future of motors through the use of the adhesive-free insulating material "Namli®."

xEV Motors Enter the Era of High-Speed Rotation

In xEVs (including BEVs, HEVs, and PHEVs), increasing driving range and reducing charging times are major factors for adopting higher voltage in electrification components.

This trend has spurred innovations such as higher-capacity batteries and advancements in power semiconductors in inverters. Naturally, xEV motors must also evolve.

Rather than increasing motor size, a common approach to boosting output while maintaining compactness and light weight is to increase the rotor's rotational speed.

Among evolving motor technologies, Permanent Magnet Synchronous Motors (PMSMs) have become mainstream in xEVs. There are two primary PMSM types:

- Surface Permanent Magnet Synchronous Motors (SPMSMs): Efficient at utilizing magnetic flux from the magnets.

- Interior Permanent Magnet Synchronous Motors (IPMSMs): Utilize both magnetic torque and reluctance torque.

In IPMSMs, magnets are embedded in the rotor, which reduces the risk of magnet scattering due to centrifugal force, making them suitable and safe for high-speed operation.

However, higher inverter frequencies required for high-speed operation lead to increased iron loss, which causes heat buildup. This can weaken structural compoenets, degrade insulation, and damage bearings, all of which shoten the motor's lifespan.

To mitigate this, efficient heat dissipation through cooling systems such as air, water, or refrigerant cooling are critical for appropriate motor design.

The Solution

ATF-Based Cooling Systems supporting High Speed Rotation and Their Challenges

ATF-based oil cooling systems are gaining traction in the market for their high cooling efficiency.

ATF not only suppresses rises in motor temperature but also acts as a lubricant, reducing heat generation and offering high electrical insulation. These qualities make it ideal for high-output motor cooling.

However, chemicals in ATF can react with adhesives used in insulation materials, potentially degrading motor performance.

Additionally, adhesives are prone to thermal degradation under high temperatures, leading to reduced insulation performance and mechanical strength over time.

Namli®: An Adhesive-Free Insulation Solution

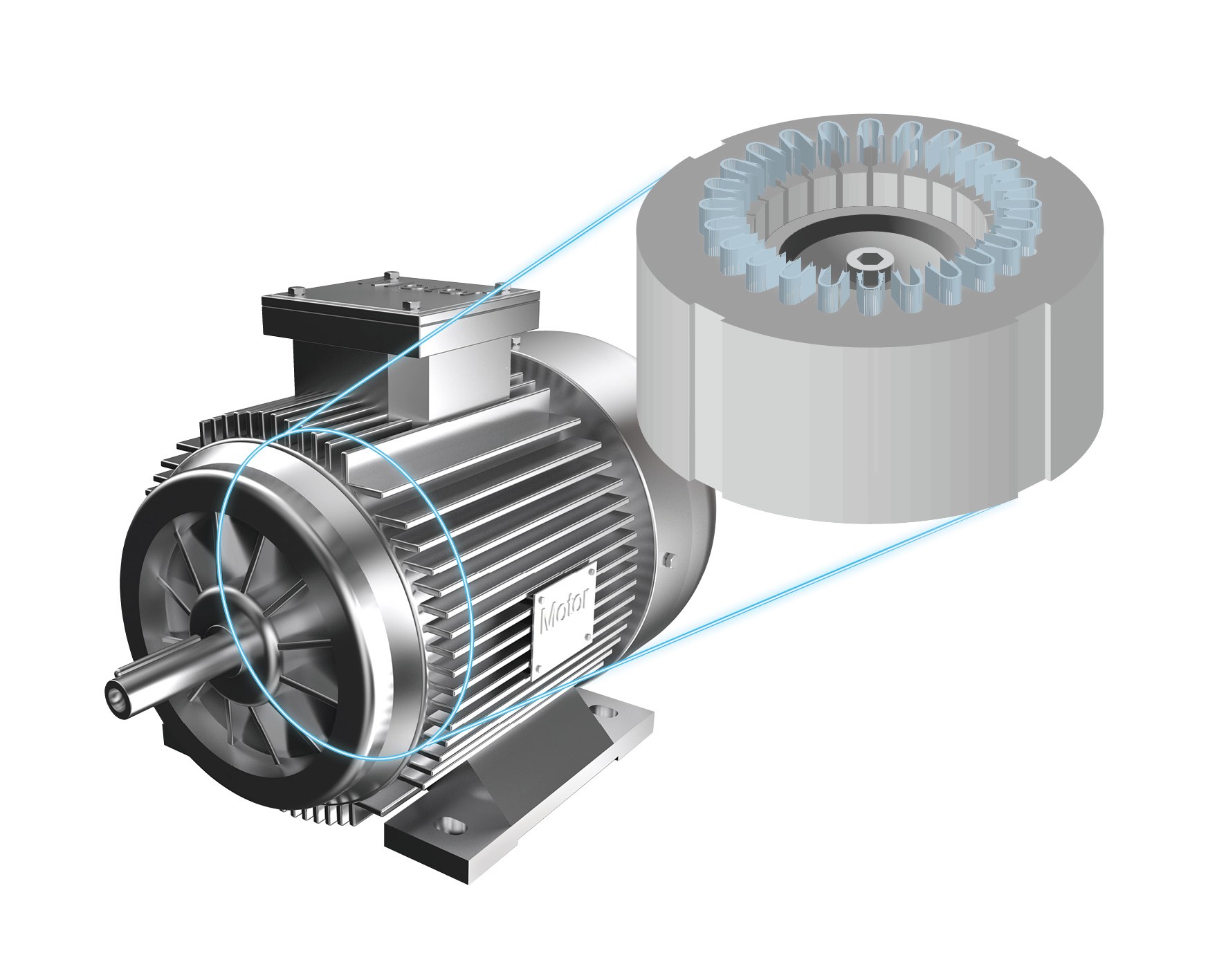

To the address these challenges, NAGASE and Kawamura Sangyo have developed an adhesive-free insulation material: Namli®.

Headquartered in Yokkaichi, Mie Prefecture, Kawamura Sangyo specializes in slitting, pressing, proprietary plasma surface treatment, and thermal lamination technologies.

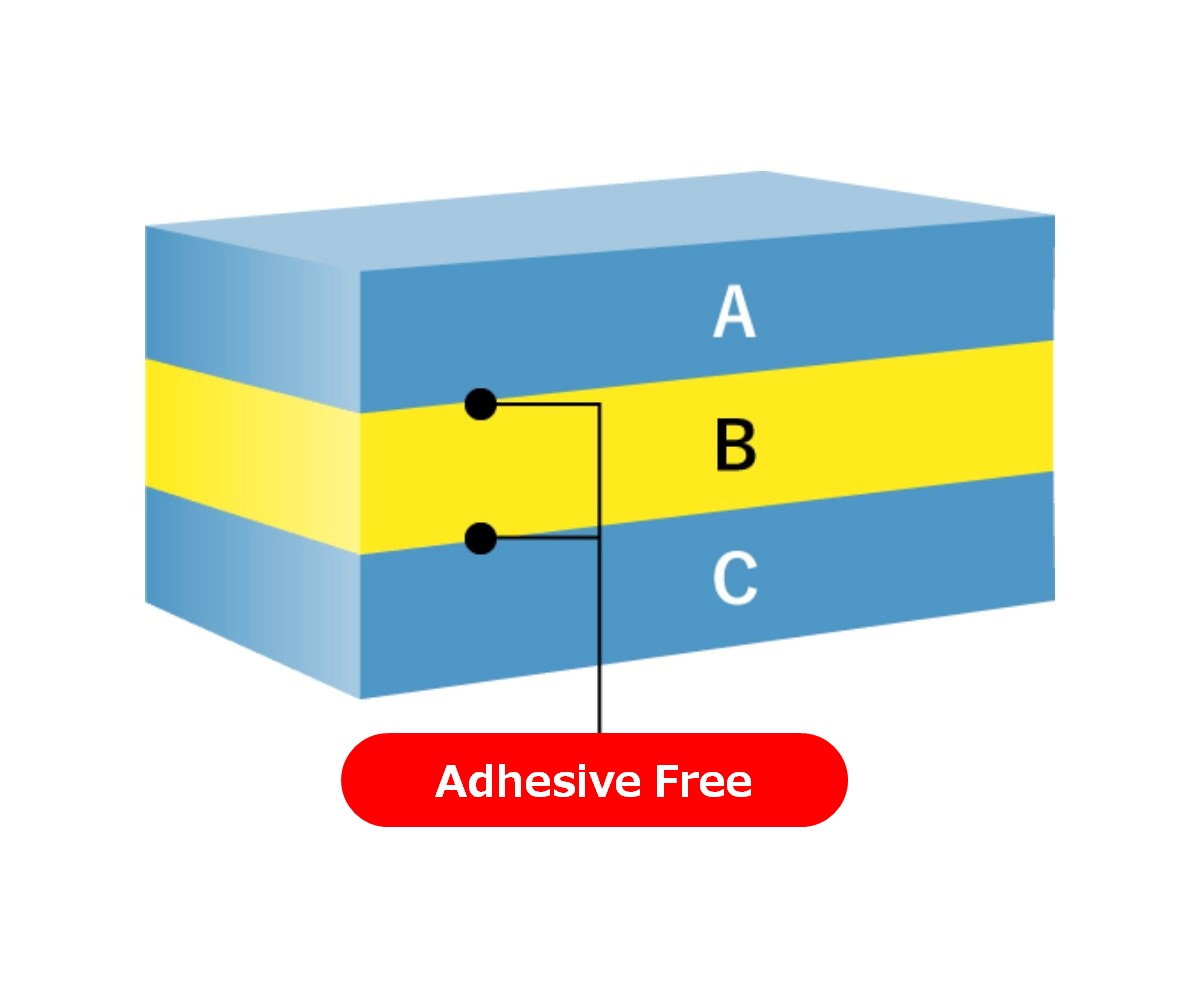

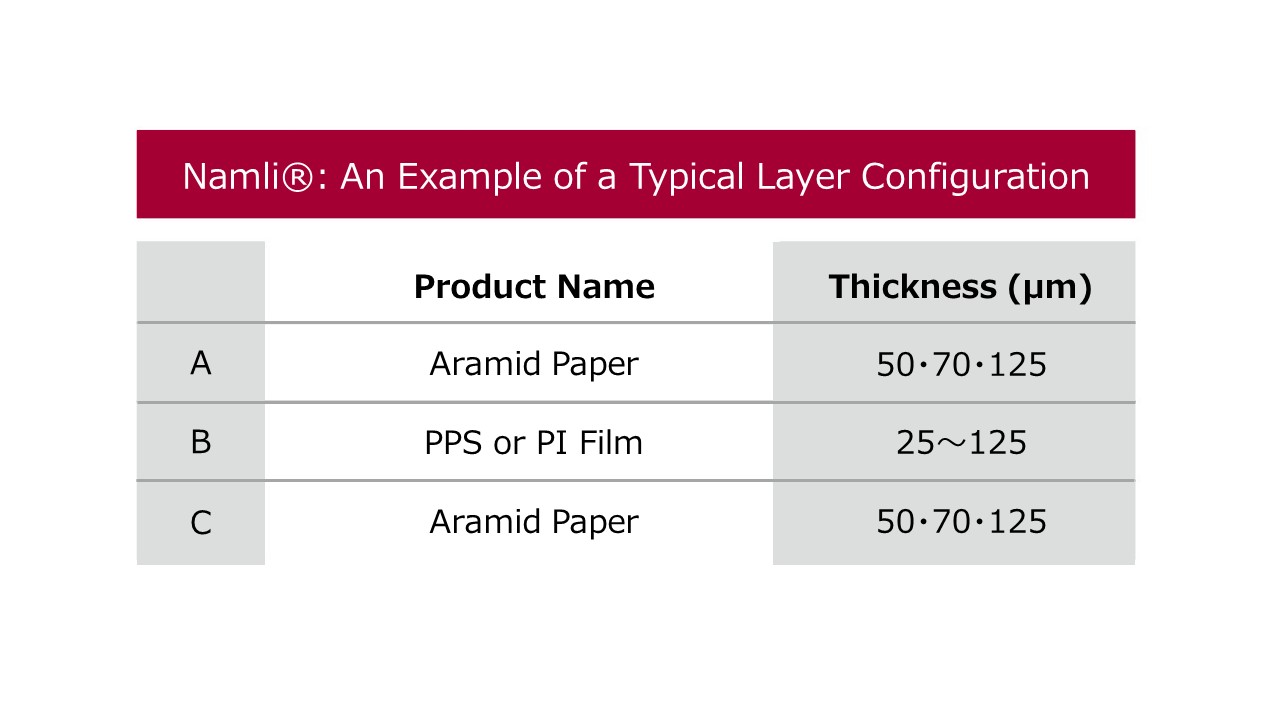

By integrating these proprietary technologies they have development Namli®, an insultating material for motors which bonds high-heat-resistant aramid paper with plastic films such as PPS or PI without using adhesives.

By eliminating adhesives, Namli® avoids performance degradation from ATF exposure and offers excellent insulation and tensile strength even in high-temperature environments.

Advanced Plasma Processing: The Namli® Manufacturing Method

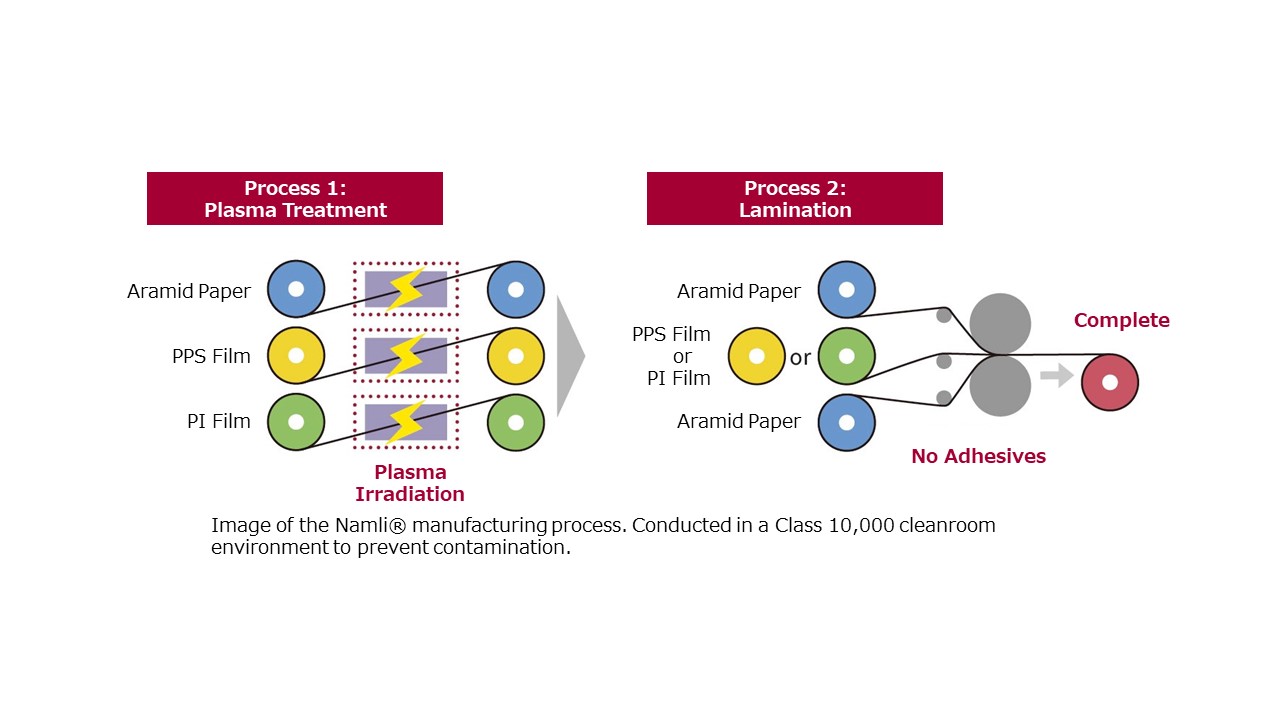

Namli® is produced in a two-step process:

1. Plasma treatment modifies the surface of aramid paper and plastic films (PPS/PI) to improve adhesion.

2. The treated materials are laminated and thermally fused to bond layers without adhesive.

This proprietary vacuum plasma technology from Kawamura Sangyo uses gases such as argon, oxygen, and nitrogen tailored to specific applications and needs.

By optimizing plasma parameters, surface treatment can be customized for diverse materials and client requirements.

Eliminating adhesives also removes volatile organic compound (VOC) emissions, contributing to reduced environmental impact and sustainability.

Namli® is already in use in domestic automotive applications and is drawing interest from international automakers, with future plans for expanded production.

Shaping the Future of Motors Through Insulation Innovation with Kawamura Sangyo and NAGASE Mobility

A rising trend in xEV motor design is increasing the slot fill ratio, the proportion of copper coils within motor slots.

A higher slot fill ratio improves motor efficiency and enables further miniaturization. This has driven demand for thinner insulation materials.

Without an adhesive layer, Namli® is thinner, more flexible for winding, and offers lower thermal resistance making it ideal for high-density coil applications.Namli® is designed to address multiple engineering challenges for xEV motors, from ATF resistance to high heat tolerance and high slot fill factors.

With Kawamura Sangyo’s proven expertise in insulation and NAGASE’s material science capabilities, Namli® offers a forward-looking solution to support the next generation of xEV motors.

For inquiries or collaboration opportunities, please contact us.