Products

NAGASE Mobility delivers innovative solutions and products for automotive applications, including electrification components, interior and exterior parts, and automotive electronics. Our portfolio further extends to wide range of functional materials such as general-purpose and engineering plastics, paints, and adhesives.

Product Categories

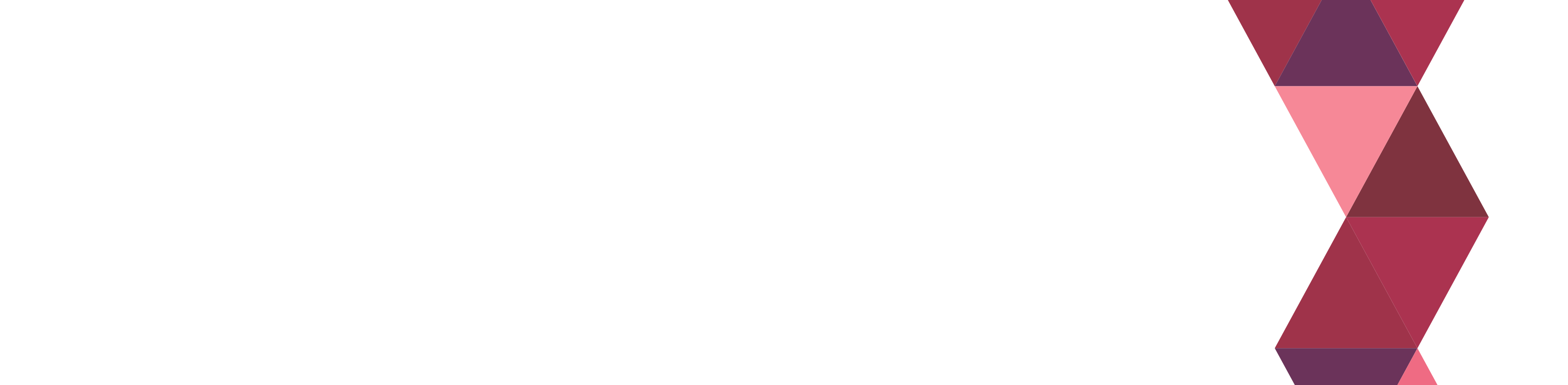

We provide highly efficient, reliable solutions that support a sustainable mobility society through next-generation battery and electrification technologies.

Category

Solutions

- Diversification of Battery Materials Supply Chain Solution

- Low Inductance Solutions

- Bonding Solutions

- Design and Development Support Solutions

- Battery Evaluation Solutions

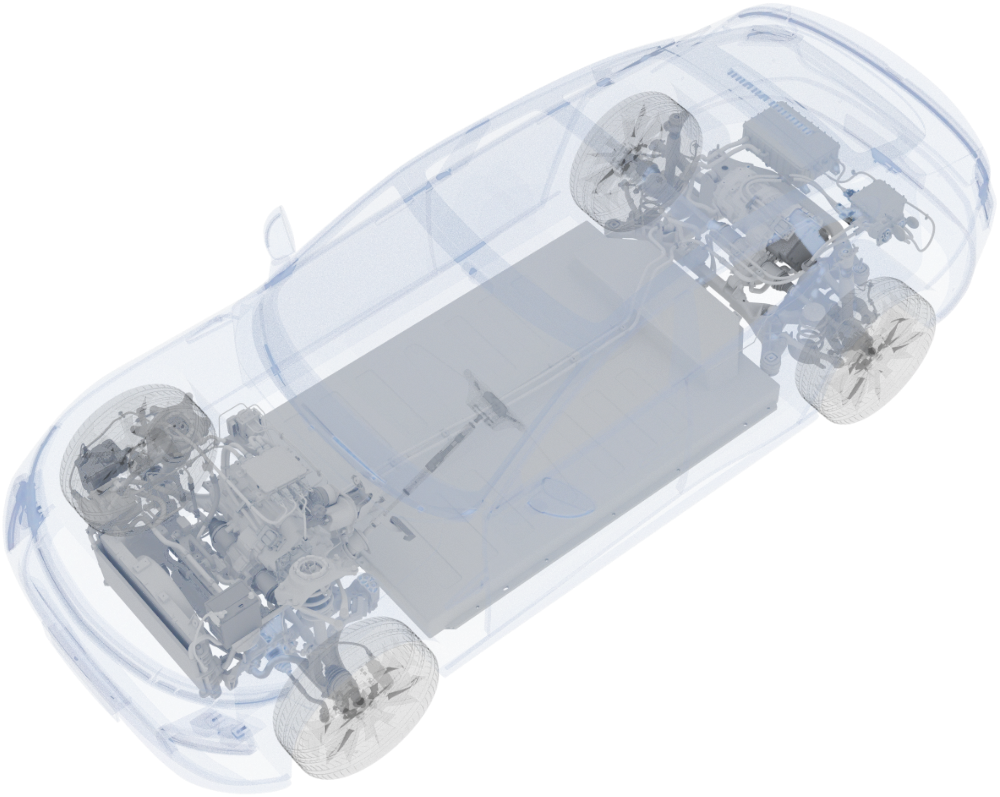

We support the development of interior and exterior components that seamlessly integrate comfort, safety, and design while elevating the user experience and meeting the expectations of next-generation transportation.

Category

Solutions

- Advanced Interior Solutions

By leveraging recycled materials and low-impact advanced substances, we support the advancement of sustainable mobility, contributing to the realization of a circular economy and a more responsible automotive future.

Category

At NAGASE Mobility, we advance eco-conscious transformation in the mobility industry by promoting the adoption of sustainable plastics. Through a multi-faceted strategy that targets greenhouse gas (GHG) reduction, we leverage the broad reach and expertise of the NAGASE Group to recommend optimal materials tailored to the unique characteristics of each product. We also confront regional regulatory landscapes head-on—addressing technical, legislative, and market challenges—to support the mobility sector’s shift to a truly circular economy.

Plastics

- Material Recycled Plastics

- Bio-Based Plastics

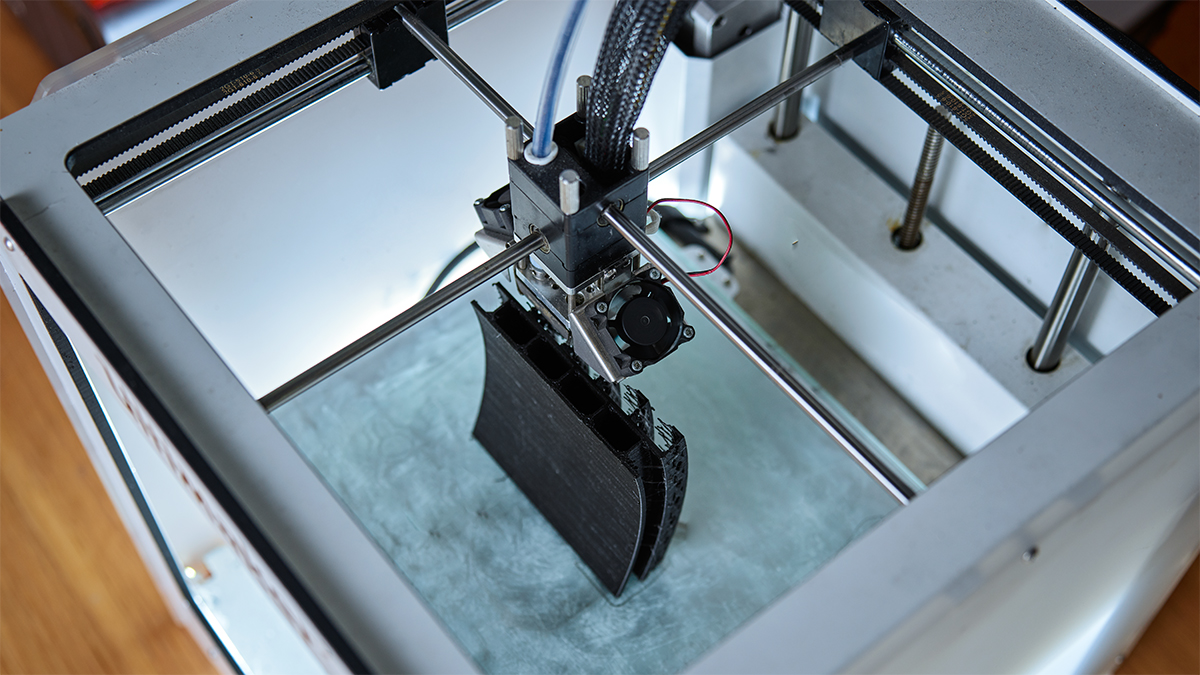

We support a broad range of advanced technologies essential to modern mobility spanning 3D printing, automotive electronics, and autonomous systems.

Category

In the automotive sector, the adoption of 3D printing for functional mass-production parts is accelerating. NAGASE Mobility has engineered improved polypropylene (PP) filaments and optimized printing parameters to enable high-precision, low-warp molding of large, complex parts like liquid flow parts.

From initial design through evaluation to mass-production processes, we offer end-to-end support that elevates 3D printing from prototyping into mainstream manufacturing.

3D Printing

- PP Filament for 3D Printing