About Deoriser

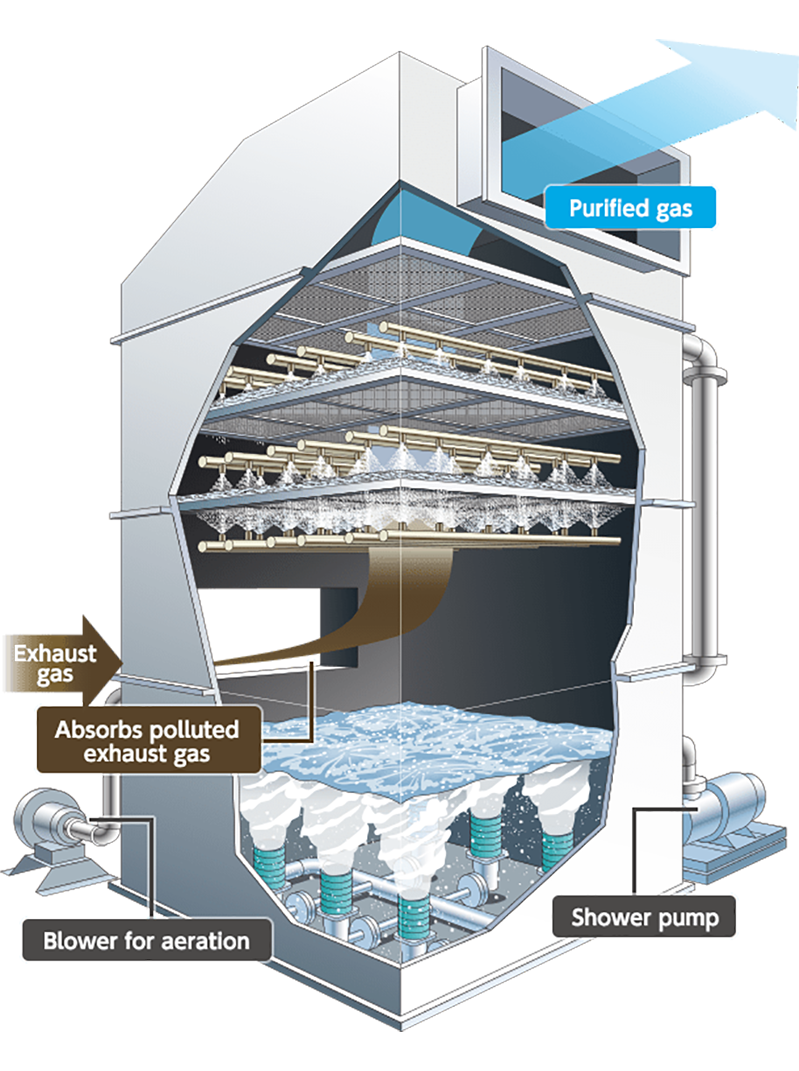

But these problems will go away. Because of the environmental solution of Nagase (Thailand) Co., Ltd., we use a circulating biodiorizer dryer (Biodeoriser) that precisely traps rotten odors and dust. With a water curtain thickness of 40 - 50 millimeters, the machine will be equipped with an aerator Aquablaster with high efficiency in wastewater treatment. Therefore, using the Wet Scrubber odor treatment system from Nagase can treat air and sewage all in one!

Working principle of exhaust gas treatment equipment

NEW!Award of Deoriser Exhaust gas treatment equipment

Feature of Exhaust gas treatment equipment

Water Film Scrubber Deorizer

The Exhaust gas treatment equipment was developed to solve the problem of unwanted odors from industrial processes. It has all the odor-eliminating features:

Water film reliably captures odors and dust

Water film is formed between 40 and 50mm in thickness, which provides outstanding gas-liquid performance to capture soluble odor and dust.

Replaceable cartridge for easy maintenance

The special design of multi-layered stainless screen generates water film and captures even paticulates of 1 micron. Furthermore, it is easy to replace the cartridge by one worker.

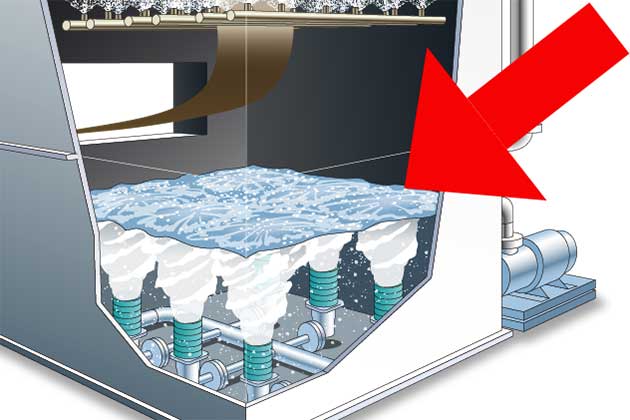

Equipped with high-efficiency "Aquablaster" diffuser pipe

Deoriser is not only a scrubber but also treats water itself by equipping Aquablaster at the bottom of Deoriser. Water circulated increases the duration of the exchange to achieve zero emission.

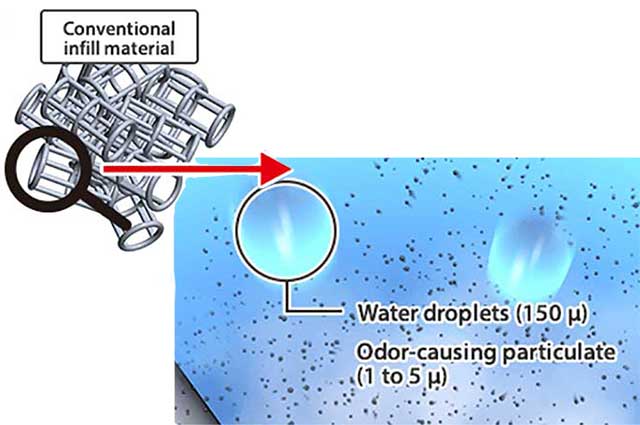

Why is water film necessary?

Examining things at the microscopic level… The width of net-type infill material is approx. 2 mm, and the openings is approx. 5 mm. At the microscopic level, odor-causing particulates have a diameter of one to five microns, and the water droplets that dislodge these particulates are about 150 microns in diameter. If we multiply by 1,000, the particulates will be 1 mm to 5 mm, and the water droplets are the size as a softball, at 15 cm. The infill material will be the width of – 2 m – while the openings are 5 m, and it is easy to see why the gas-liquid contact is poor.

Bio Deoriser odor reduction rates

| Substance | Concentration reduction rate for substance | Solubility in water | Neutralization | Flow-through velocity | |

| Nitrogenous compounds | Ammonia | ○ | 54g/100ml | Required | 0.75~1.0 m/sec |

| Trimethylamine | ○ | 108g/100ml | |||

| Sulfurous compounds | Methyl mercaptan | ○ | 2.3g/100ml | Required | 0.75~1.0 m/sec |

| Hydrogen sulfide | ○ | 0.67g/100ml | |||

| Aldehydes | Formaldehyde | ○ | Completely soluble | Not Required | 0.5~0.75 m/sec |

| Acetaldehyde | ○ | Freely soluble | |||

| VOC | Ethyl acetate | △ | 8.7g/100ml | Not Required | below 0.5m/sec |

| Methyl isobutyl ketone | △ | 1.8wt% | |||

| Fatty acid | Propionic acid | △~○ | Unknown | Required | 0.75~1.0 m/sec |

| Normal butyric acid | △~○ | Unknown | |||

DEORISER's Special Function For Environmental Solution.

Installation Examples of DEORISER Exhaust gas treatment equipment

Casting plant

Casting plant exhaust gas treatment

In the casting line, strong odors such as the smell of resin were generated and it was a problem both inside and outside the foundry. Using 4 units of film type scrubber Deorizer DR-30W, the exhaust gas with a maximum wind speed of 1.83m/sec is treated with a liquid film. The work environment has greatly improved. We also received additional orders for other line deorisers on repeat.

Organic solvent

Organic solvent exhaust gas treatment

The factory's manufacturing process uses organic solvents to purify the equipment. The odor from organic solvents has a huge impact on office workers. For the above reasons, the factory therefore chose to install 1 Deoriser with a wind power of 450㎥/min, which can reduce the odor from 1000ppm down to below 400ppm.

Chemical plant

Chemical plant exhaust gas treatment

The customer demanded to reduce the concentration of formaldehyde gas generated during the production process, which affects the body of the workers on the jobsite. We therefore designed the DR-30W Deoriser with a suitable internal airflow of 0.68m/sec. As expected, only large amounts of carbon disulfide and hydrogen sulfide were captured, but over 95% of formaldehyde was captured.

Why do they have to use exhaust gas treatment equipment

For these reasons, industrial plants need to bring in exhaust gas treatment equipment such as Deorizer to help trap unwanted odors and not to pollute the environment around the factory's air.

Address

ที่อยู่บริษัท

- Nagase (Thailand) Co.,Ltd.

- No.952 Ramaland Building 14th Floor, Rama IV Rd., Kwaeng Suriyawongse, Khet Bangrak, Bangkok 10500 Thailand